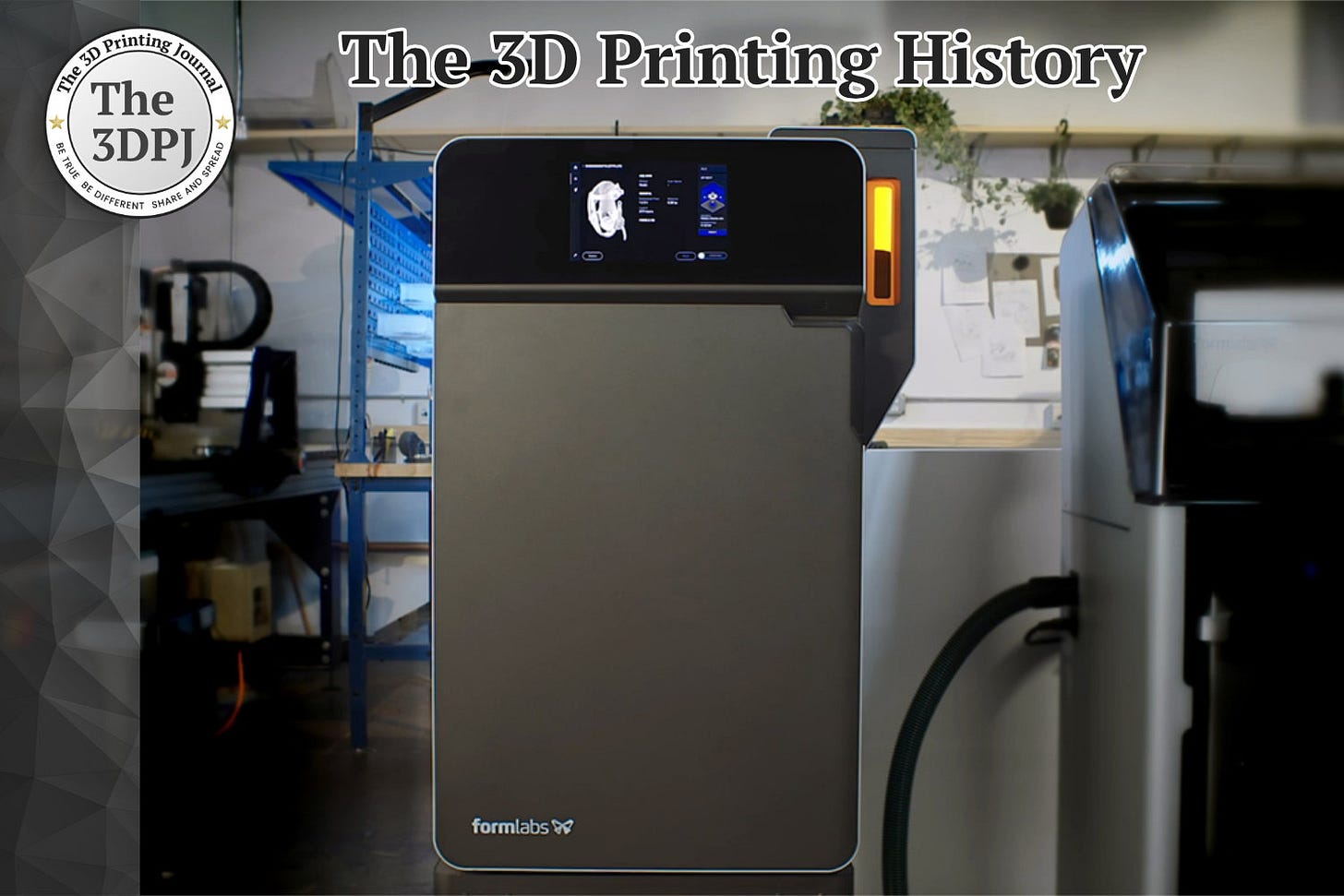

01-26-2021: Formlabs (finally) launched Fuse 1 – its first SLS 3D printer

The company also introduced the Fuse Sift post-processing system and Nylon 12 Powder material

On January 26, 2021, Formlabs announced the market launch of Fuse 1, its first desktop-grade 3D printer using Selective Laser Sintering (SLS) technology. Along with Fuse 1, the company also introduced the Fuse Sift post-processing system and Nylon 12 Powder material, aiming to provide users with a comprehensive SLS workflow.

Formlabs' Fuse 1 entered the desktop SLS 3D printing market as a key competitor to Swiss-based Sintratec and Polish company Sinterit, both of which had been operating for seven years by then. However, compared to these relatively small startups, Formlabs – already a leader in the desktop 3D printing market thanks to its photopolymer-based Form 1, Form 2, and Form 3 printers – was a force to be reckoned with. In fact, thanks to solid technological solutions, a complete ecosystem, and relatively low pricing, Formlabs quickly gained the upper hand in the market.

Today, the company claims to deliver 50% of all SLS systems globally. Sintratec couldn’t keep up and declared bankruptcy last year, while Sinterit is no longer in a position to pose any serious threat to Formlabs.

But back in 2021, the situation didn’t look so promising. Fuse 1 was initially unveiled in 2017 and presented as the result of years of R&D efforts. However, in the years that followed, little progress seemed to be made. While beta testing of the device was announced in 2018, Fuse 1 remained a virtual product, apart from promotional materials.

By 2021, SLS at Formlabs was mostly discussed in the context of potential failure. A three-year delay in market release raised serious concerns about the project, which was seen as major false start.

However, those fears turned out to be unfounded. The company delivered a fully functional 3D printer that immediately began to dominate the still-nascent desktop SLS market.

Fuse 1 featured a 10 W laser that provided print precision down to 110 microns. The Surface Armor technology patented by Formlabs created a semi-sintered shell around the printed object, protecting it from mechanical and thermal damage during the printing process. The minimum material refresh rate was 30%, and the printer came with a modular build chamber measuring 165 x 165 x 320 mm.

Accompanying the Fuse 1 was Formlabs' proprietary Nylon 12 powder, which offered high strength, flexibility, and abrasion resistance, making it ideal for functional prototypes and end-use parts. The printer was also compatible with the Fuse Sift system, which automated cleaning and powder recovery.

The Fuse 1 3D printer launched at a starting price of $18,499, significantly lowering the entry point for SLS technology compared to traditional industrial-grade SLS machines.

Source: www.formlabs.com