01-27-2014: Markforged introduced the Mark One 3D printer

It was the company’s official debut in the market

On January 27, 2014, during the SolidWorks World conference in San Diego, an unknown startup named Markforged unveiled a prototype of the world’s first 3D printer capable of printing with continuous carbon fiber. This groundbreaking event introduced a technological solution that allowed the creation of high-strength, lightweight components—previously achievable only through advanced industrial processes.

It was also the official debut of one of today’s most influential companies shaping the global AM market.

The 3D printer, called the Mark One, was developed by Gregory Mark, the founder of the company and an aerospace engineer from MIT. Mark had previously worked on producing high-performance wings for race cars at Aeromotions. His experience with composites, including carbon fiber, inspired him to create a 3D printer that could automate the process of laying composite layers. Carbon fiber, a key material for the Mark One, stood out for its exceptional strength and stiffness paired with low weight, making it ideal for applications in the automotive and aerospace industries.

The Mark One utilized a proprietary technology called Composite Filament Fabrication (CFF), which combined traditional FFF 3D printing with the ability to embed continuous carbon fibers into the print structure. This innovation allowed the printed parts to achieve strength surpassing that of aluminum used in the aerospace industry.

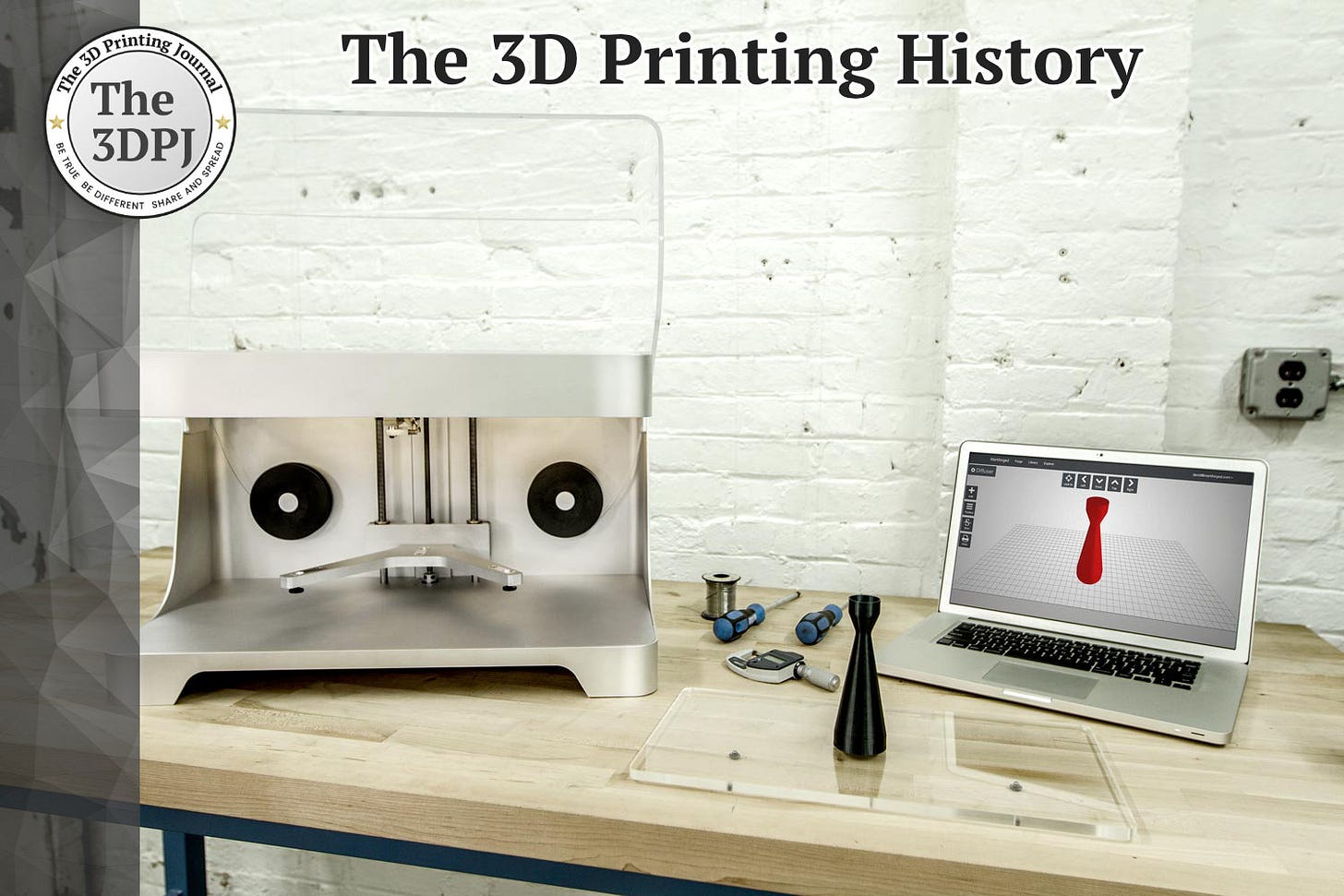

The 3D printer featured a build volume of 305 x 160 x 160 mm, dual interchangeable print heads, and support for materials such as carbon fiber, fiberglass, nylon, and PLA. The Mark One was also notable for its design—an anodized aluminum frame and a precision bed-leveling system made it both functional and user-friendly.

The printer was priced at $4,999, with pre-orders announced for February 2014.

In subsequent years, Markforged continued advancing carbon fiber printing technology, releasing new models like the Mark Two and X7. The company gained industry recognition for its innovative solutions, enabling the production of functional, high-strength parts without the need for traditional CNC machining.

Markforged’s technology significantly influenced the 3D printing industry by popularizing composite printing. The company expanded its range of usable materials to include fiberglass, Kevlar, and high-temperature-resistant materials.

Of course, the history of Markforged is much more complex—ranging from infamous patent wars with Desktop Metal to the “theoretical” acquisition of the company by Nano Dimension. However, those stories are for another occasion.

As for Greg Mark, he left Markforged on December 31, 2021, and is now developing a software startup called Backflip.

Source: www.markforged.com