03-02-2022: BCN3D introduced a new resin-based 3D printing technology

This innovation later led to the creation of the company Supernova

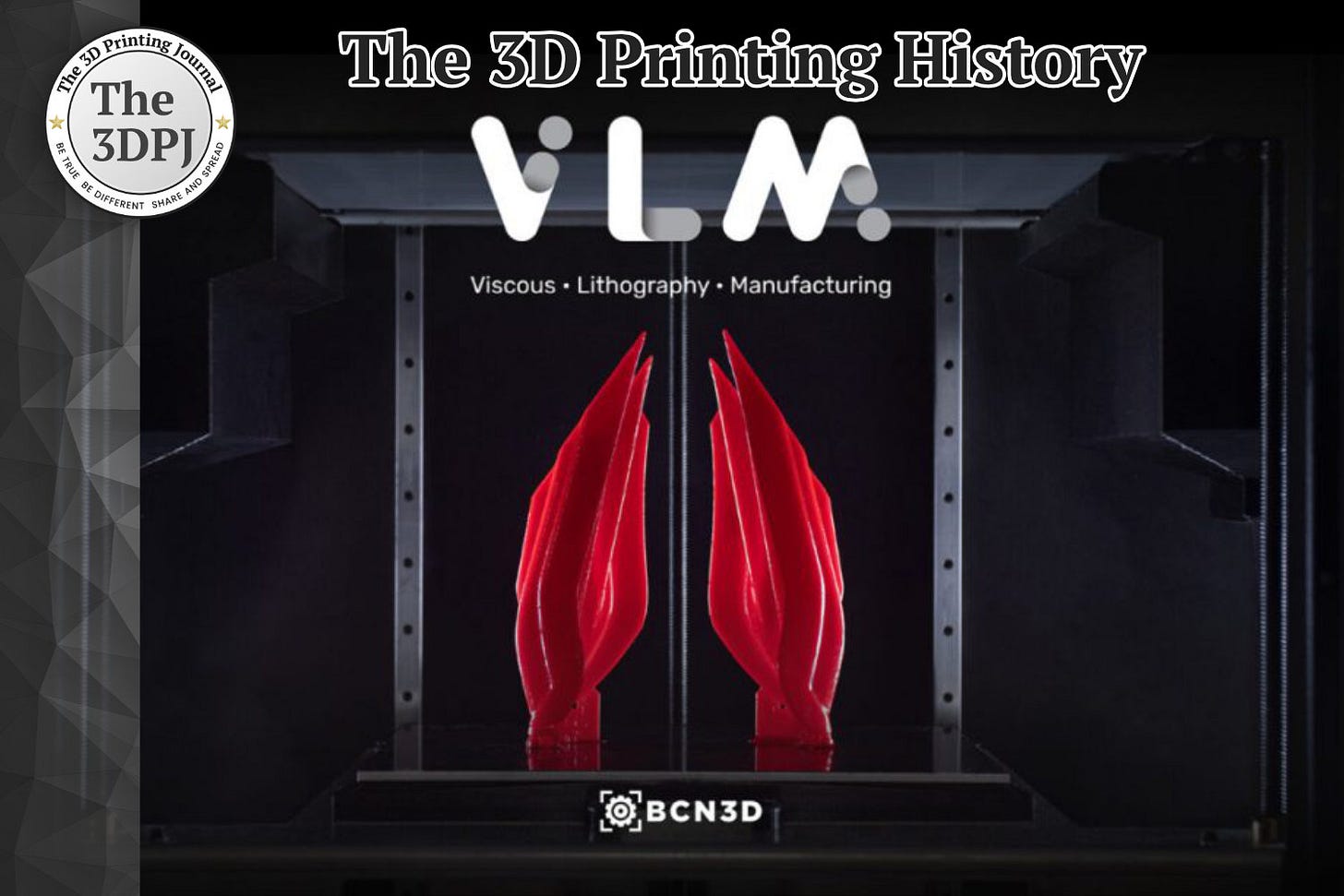

On March 2, 2022, BCN3D unveiled a completely new technological solution in the field of photopolymer resin 3D printing—Viscous Lithography Manufacturing (VLM). This process utilized high-viscosity photopolymer resins that were selectively cured using UV light, resulting in enhanced physical and chemical properties not achievable with other resin-based technologies. These improvements included triple the impact resistance and twice the tear strength compared to conventional resin-based prints.

What set VLM apart from SLA or DLP was its radically different approach to part fabrication. In typical desktop resin printers, the light source is positioned at the bottom, with a resin vat above it. The build platform descends into the resin, and the 3D model adheres to it as it is built layer by layer. VLM, however, flipped this process entirely.

Instead of a single resin vat, the VLM machine housed two separate resin reservoirs on either side of the printer. Each reservoir had a roll of film coated with a layer of resin, which was then advanced into the center of the printing chamber. The build platform moved upward from below, pressing against the resin-coated film at the first layer's height, while an LCD screen above selectively cured the resin. After exposure, the platform lowered, detaching the printed layer from the film, which was then rewound into the resin reservoir. Excess resin was collected, and a fresh resin layer was applied to the cleaned film, repeating the process layer by layer.

The dual-resin system allowed for two possible advantages - the ability to print with two different resins (e.g., a structural resin and a dissolvable support resin with distinct chemical properties), or faster printing, as while one section of the film was being cleaned and recoated with resin, another section was already undergoing photopolymerization.

The first beta users of VLM technology were major players in the automotive industry: Saint-Gobain, a leading manufacturer of automotive glass, and Prodrive, a world-renowned motorsports and advanced technology company.

In January 2024, BCN3D spun off its VLM division into an independent company called Supernova. The new company is registered in the United States and operates from Austin, Texas, as well as Barcelona, Spain.

Supernova focuses on implementing VLM technology for production applications, offering solutions that combine high quality, productivity, and competitive cost per part. In August 2024, the company announced the launch of a Defense & Space division, expanding its focus into the aerospace and defense sectors.

Source: www.centrumdruku3d.pl