03-04-2016: Autodesk revealed Project Escher for super-fast, multi-head 3D printing of large-scale parts

Never commercialized, it’s worth preserving it from being forgotten

On March 4, 2016, Autodesk launched Project Escher, aiming to accelerate the 3D printing process by utilizing multiple print heads simultaneously. Thanks to advanced control software, it was possible to coordinate the operation of several heads, significantly reducing the time required to print very large objects. Unfortunately, despite its intriguing approach and theoretically high potential, Project Escher was never commercialized, and its further fate remains unknown.

From the very beginning of 3D printing technology, production speed has been one of its most controversial aspects. While common sense suggests that compared to traditional manufacturing methods, it is unquestionably faster (and often cheaper), in the eyes of ordinary people who have only encountered consumer-grade 3D printing or serial production, additive manufacturing is perceived as slow. This was particularly emphasized in the mid-2010s, though in 2023, Bambu Lab significantly changed this perception.

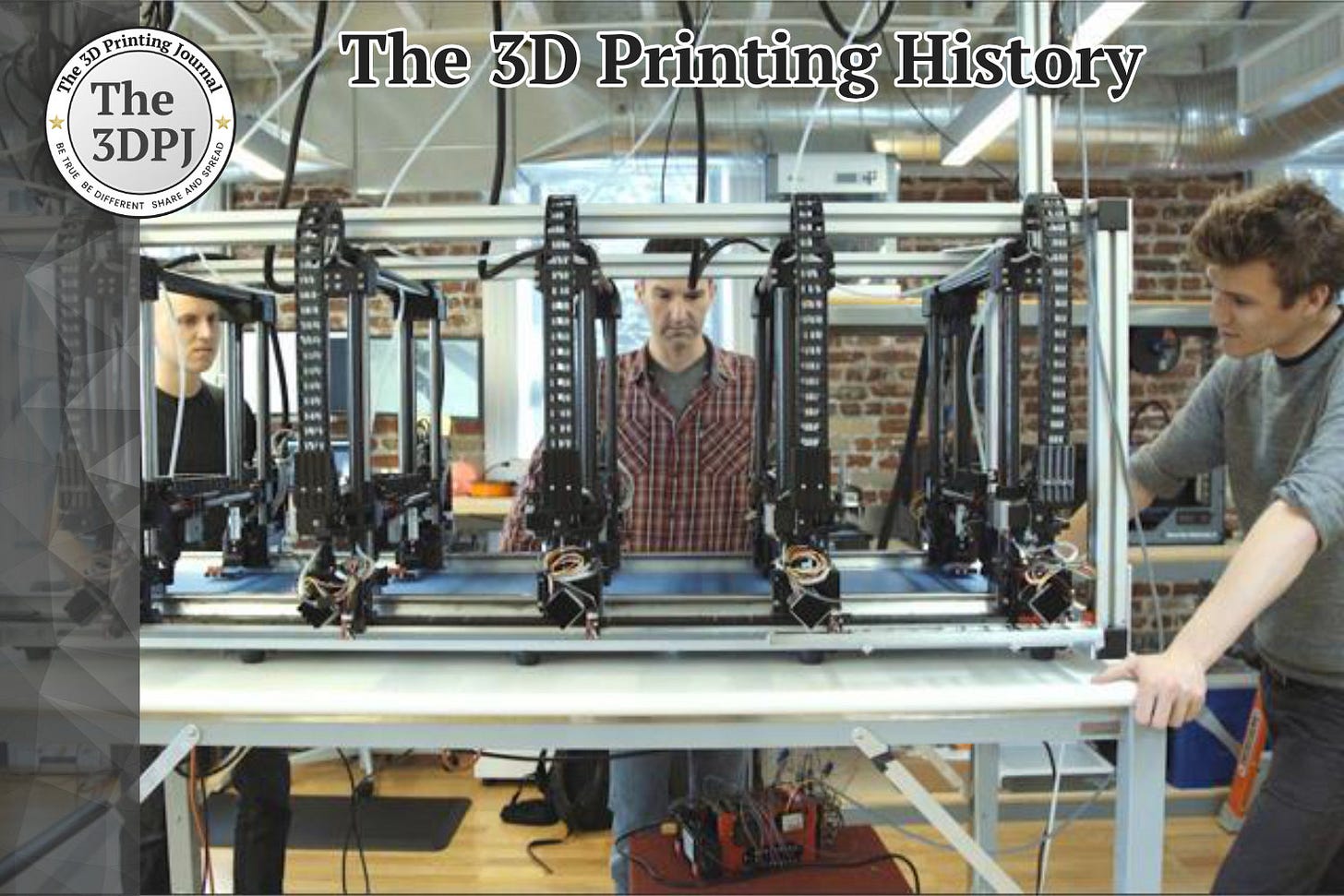

Since the consumer 3D printing revolution, Autodesk had been strengthening its position in the additive manufacturing industry by creating various intriguing projects (such as the Ember 3D printer, Spark software, and the 3MF format). Project Escher, in turn, was intended to dramatically accelerate FFF 3D printing. The 3D printer went far beyond conventional notions of such devices, resembling a professional production line rather than a standard printer.

Escher consisted of a massive frame with five print heads mounted on it, moving independently along the XYZ axes. During operation, the print heads moved separately along the XY axes, layering the material. Once a layer was completed, they would lift in the Z-axis and continue the process.

The key to success was the software, which enabled the simultaneous operation of up to five independent print heads. Since each head was dedicated to building a different section of the model, the process was theoretically five times faster than with traditional single-head printers. In reality, the speed increase depended on the size and geometry of the object. Escher was designed for large-scale 3D printing, and its application made sense only in such cases.

This innovative 3D printing process was developed by Autodesk’s research team under the leadership of Andreas Bastian. It was given the working name "collaborative fabrication" and was powered by software based on Autodesk’s Conductive Player architecture.

Bastian believed that Escher would become a refined enough manufacturing system to begin commercial implementation as early as 2017–2018. The project was not intended to be limited to 3D printing. Theoretically, each head installed in the machine could be equipped with a different tool, offering vastly greater manufacturing capabilities. The system could also be expanded with additional heads, meaning the number of processes that could be performed depended largely on the user's needs.

Unfortunately, that never happened. But it's worth remembering as one of the many accomplishments of the past.

Source: www.centrumdruku3d.pl