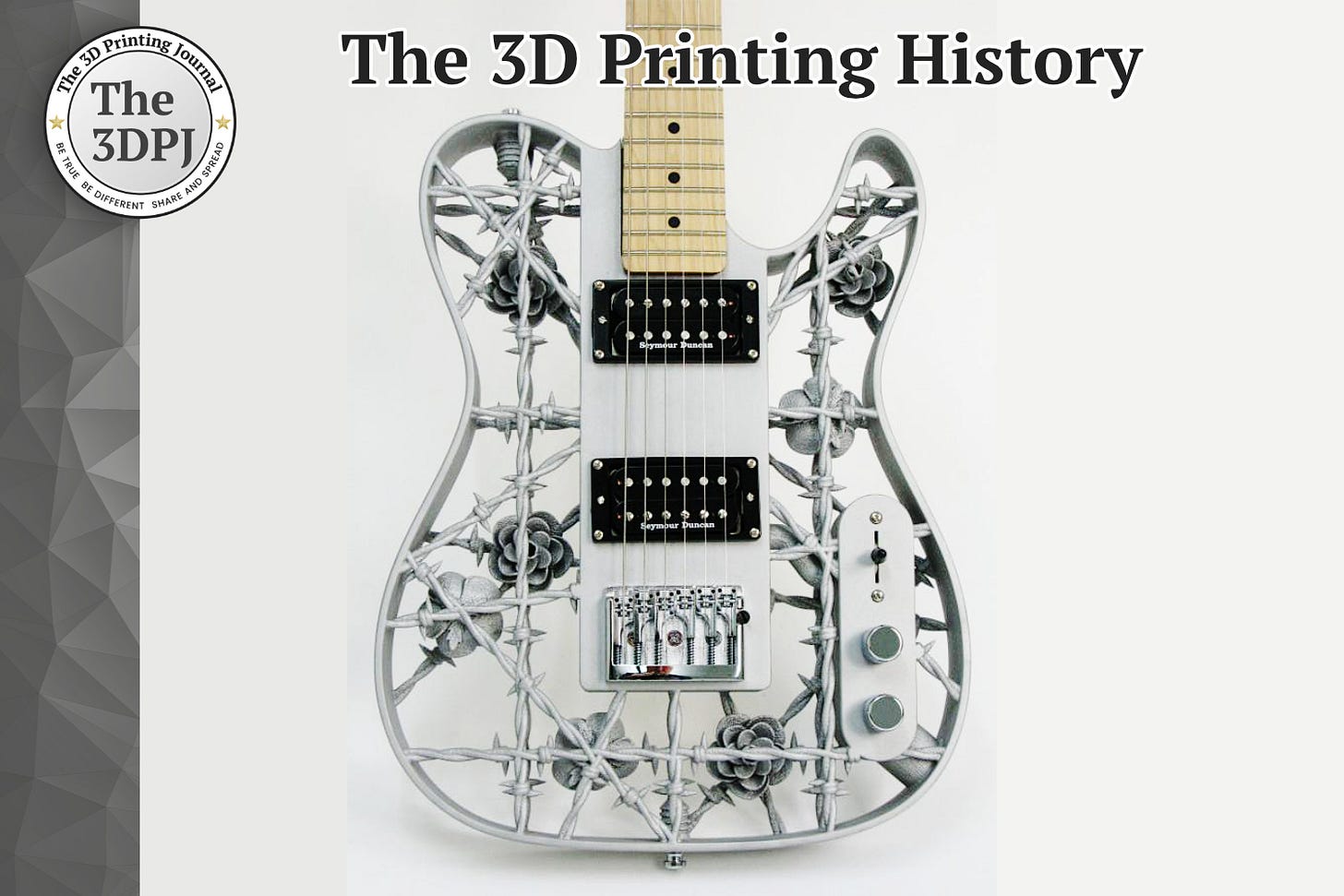

05-05-2016: Olaf Diegel presented Heavy Metal – the world’s first guitar 3D printed from aluminum

Olaf Diegel gained international recognition as the creator of extraordinary musical instruments produced through 3D printing

On May 5, 2016, Olaf Diegel announced the creation of the world’s first guitar made of aluminum using 3D printing technology. The instrument, named Heavy Metal, was designed as a showcase of the capabilities of metal additive manufacturing, while also serving as an artistic expression of the potential of digital fabrication. Diegel, a professor at Lund University, was widely known in the AM industry for combining advanced engineering with music.

Olaf Diegel gained international recognition as the creator of extraordinary musical instruments produced through 3D printing. He designed numerous guitars with unique styles, including steampunk-inspired models and a custom guitar for the Steve Miller Band. His portfolio also included a fully functional 3D-printed saxophone and an entire line of instruments showcased during the world’s first concert performed entirely with 3D-printed instruments. He also collaborated with students on medical design projects, including innovative prosthetic solutions. Diegel earned a reputation as a true “Renaissance man” in the world of additive manufacturing.

The Heavy Metal guitar was developed as a research experiment to test the limits of metal 3D printing. The body of the instrument was designed in SolidWorks CAD software and printed in aluminum using the Powder Bed Fusion (PBF) process on an EOS M400 industrial printer. This method involves depositing thin layers of aluminum powder, which are selectively melted by a laser. Due to the high temperatures required for sintering metal and the complex geometry of the part, special support structures were needed to act as heat sinks — dissipating excess heat to prevent stress buildup and warping.

While the outer shape of the guitar was inspired by the classic Telecaster model, it was radically reimagined with intricate industrial and floral motifs — including barbed wire and roses. All of these fine details were printed as a single piece, something that would be virtually impossible using traditional manufacturing methods. Once printing was complete, an intensive post-processing phase began. Diegel had to first saw the printed body off the build plate, then manually remove all support structures — a process that took about four days.

After cleaning the model, the finishing phase began. The printed metal had a rough, matte texture similar to raw sand-cast aluminum. To give the guitar a refined appearance and smooth texture, Diegel spent an additional four days manually filing and sanding the details using precision hand tools. The body was then shot-peened with glass beads, resulting in a satin-like, uniform surface finish. This was a highly time-consuming process, but essential to ensure the guitar not only sounded good, but also looked like a work of art.

After final assembly — including the neck, internal wooden core, bridge, and electronics — the Heavy Metal guitar weighed just around 3.6 kilograms. Its light weight was one of the key reasons for choosing aluminum as the structural material. Despite its aggressive name and styling, the instrument proved to be surprisingly ergonomic and fully functional.

Source: www.3dprint.com