07-03-2014: colorFabb presented the first consumer version of 3D printing pellets

The new product was aimed mainly at hobbyists and amateurs

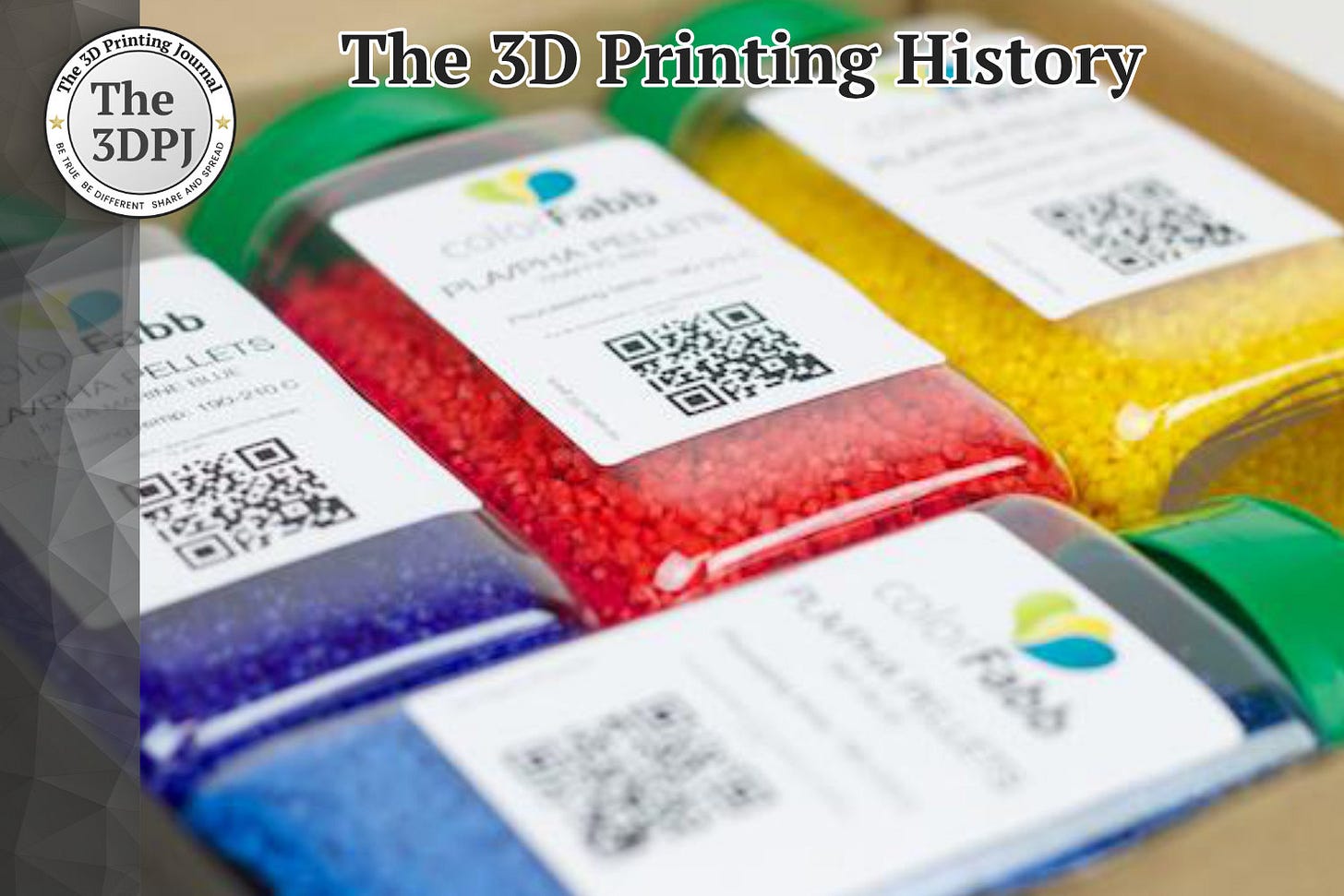

On July 3, 2014, colorFabb announced the start of sales of 3D printing materials in FDM/FFF technology in the form of pellets. The new product was aimed mainly at hobbyists and amateurs who had their own, home filament extruders like Filabot. colorFabb offered customers test kits containing four jars of pellets, which could be selected in any color combination. Each kit weighed 1.2 kg.

Although today the purchase of pellets is clearly associated with 3D printing on a dedicated 3D printer, in 2014 this product was targeted at a completely different group of users and other devices. And the reason was quite prosaic - lowering the price...

colorFabb (rightly!) noticed that 3D printer filaments are very expensive, which discouraged many potential users from buying 3D printers. Granulate is a cheaper alternative to traditional filaments on spools, which is why the company decided to introduce five granulates to the market: colored PLA/PHA, PLA/PHA, PLA, woodFill and XT-kopolyester. The price was about twice lower.

The new product was intended mainly for DIY enthusiasts and small companies involved in the production of filaments, but in the future it was also to serve other start-ups involved in the production of 3D filaments. To use the granulate, a filament extruder was needed, which processed the raw material into filament, which could then be used in a 3D printer.

The machines for amateur production of filament from granulate that were on the market at that time included Filabot, FilaFab and Filamaker (the popular 3Devo was created only in 2016).

Unfortunately, the concept of producing filament at home – whether from professional granulate from companies such as colorFabb, or from the remains of failed 3D prints, or plastic waste – never gained wider recognition. Or rather – everyone praised it and encouraged its use, but few actually did it. There were many reasons for that – the most important being the very low production efficiency and low quality of the final product.

Source: www.3dprint.com