08-24-2016: Stratasys presented Infinite Build and Robotic Composite demonstrators

Although groundbreaking, both remain among the most obscure Stratasys products ever introduced to the public

On August 24, 2016, Stratasys unveiled two innovative additive machines: the Robotic Composite 3D Demonstrator and the Infinite-Build 3D Demonstrator. The company announced their public debut during the IMTS 2016 trade show, held in mid-September in Chicago. As part of their “SHAPING WHAT’S NEXT” vision, Stratasys offered a preview of what was to come in their product lineup and additive manufacturing as a whole.

Unfortunately, beyond these demonstrations and alleged implementations in select companies and institutions, the technologies were never truly commercialized. As we know, Stratasys eventually moved in a much more conventional direction.

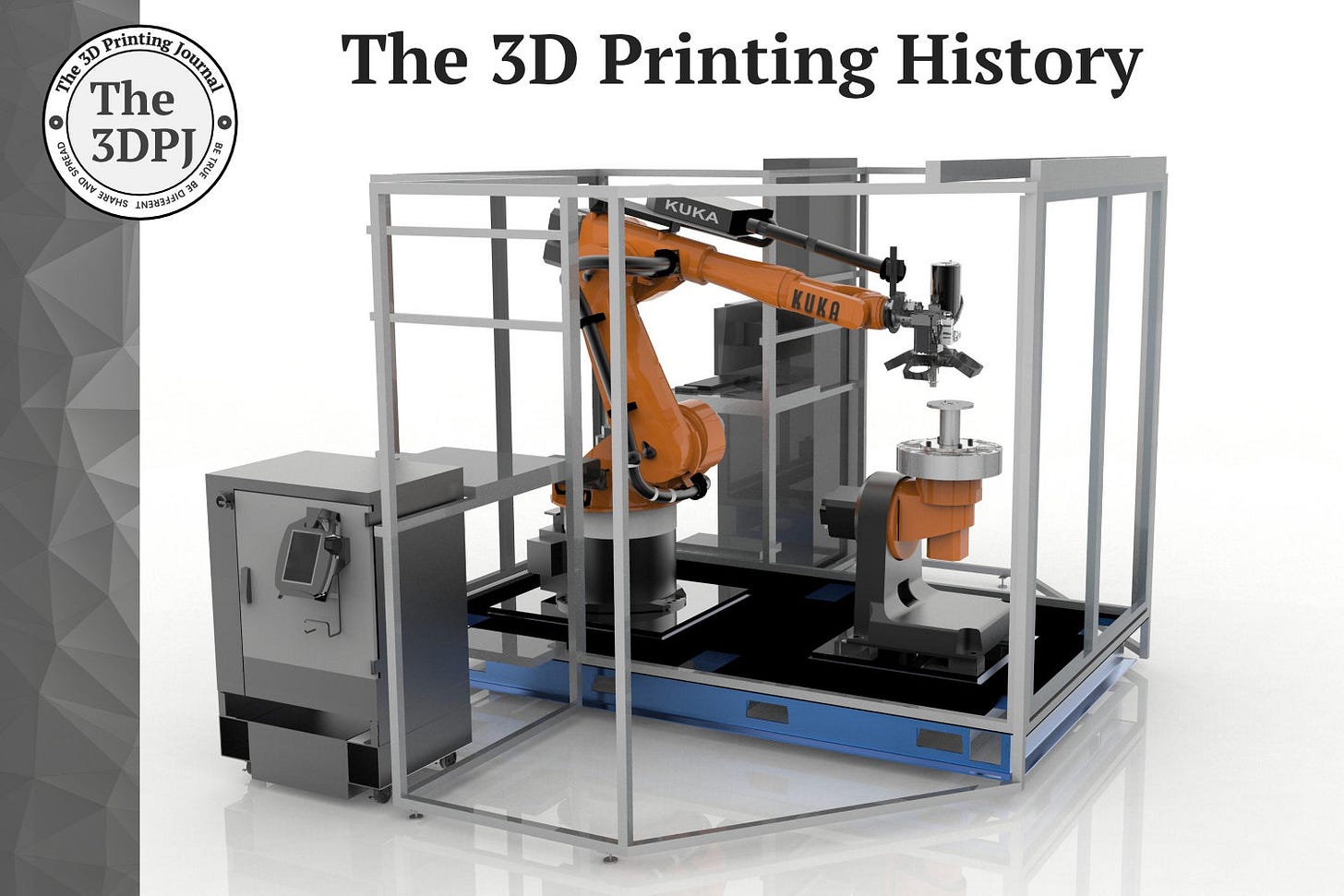

The Robotic Composite 3D Demonstrator was developed in collaboration with Siemens. Stratasys combined their manufacturing processes with Siemens’ industrial motion control hardware and software. The demonstrator used an 8-axis motion system for precise, directional material placement, enabling the production of strong parts without the need for support structures. It was also designed for the use of composite materials to produce strong, lightweight structures.

The intended recipients of this technology were (as always) the automotive and aerospace industries, as well as the oil and gas and medical sectors.

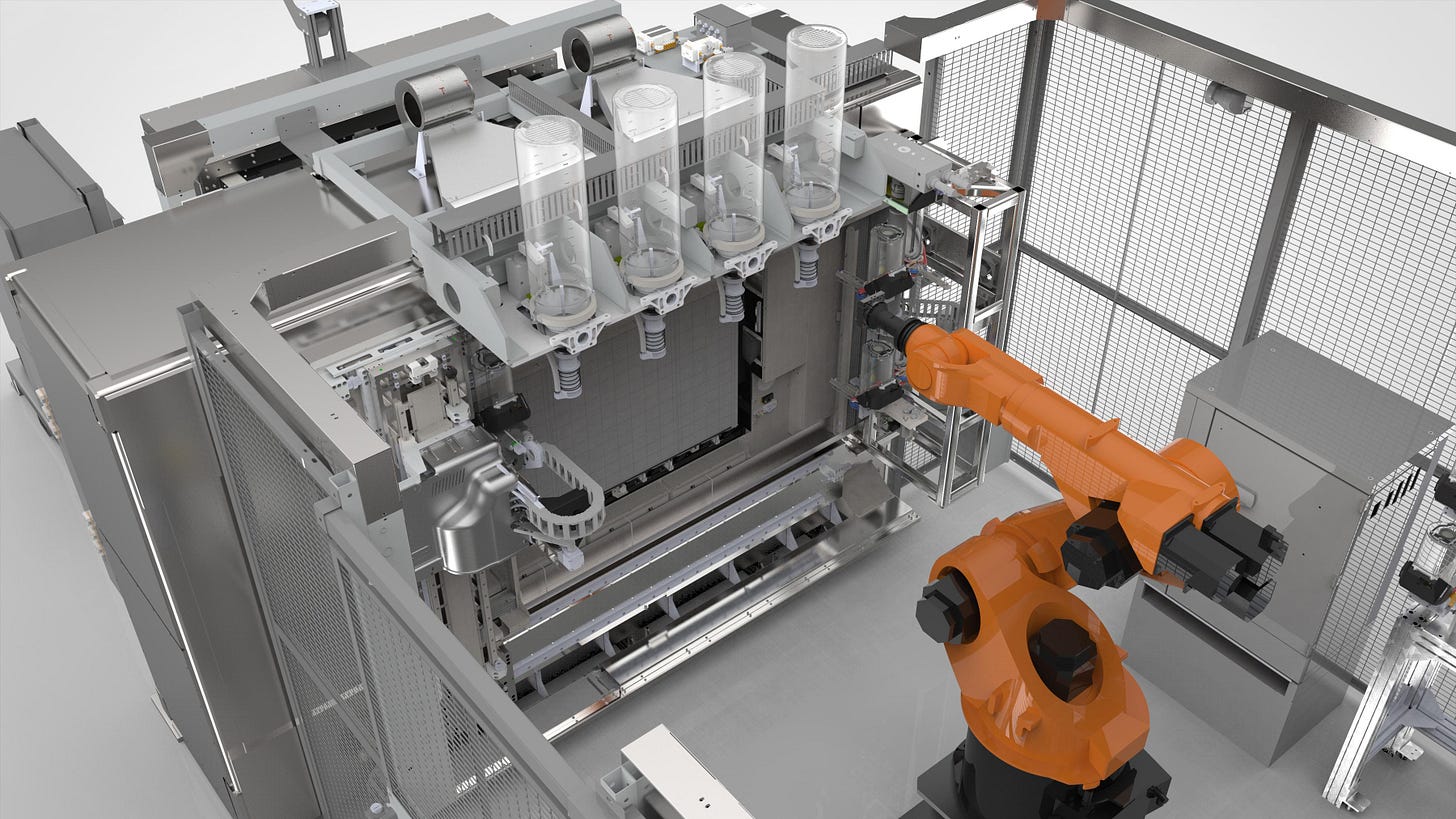

The Stratasys Infinite-Build 3D Demonstrator featured a brand new approach to FDM extrusion that reportedly increased throughput and repeatability. The system’s “infinite-build” approach involved 3D printing on a vertical plane, allowing for practically unlimited part size in the build direction.

It was said that Boeing played an influential role in defining the requirements and specifications for the demonstrator. Boeing was supposedly using the Infinite-Build 3D Demonstrator to explore the production of low-volume, lightweight parts. Additionally, Ford was exploring new automotive manufacturing applications for this demonstrator and was evaluating the new technology. Ford and Stratasys worked together to test and develop new applications for automotive-grade 3D printed materials that were previously not possible.

Despite considerable media buzz and potential interest from other customers, the project was never commercially mass-produced. The only brief mention of these technologies can be found in the “demonstrators” section on the Stratasys website, although most of the other videos presenting them are no longer available.

Source: www.stratasys.com