10-04-2022: SPEE3D launched the XSPEE3D – the metal AM system for cold spraying

The innovative 3D printer was designed for operation in challenging battlefield conditions

On October 4, 2022, Australian SPEE3D introduced the XSPEE3D, a groundbreaking containerized system designed to revolutionize the production of metal parts in the field. With its ability to print metal parts up to 1,000 times faster than traditional systems, the XSPEE3D marked a new chapter in defense manufacturing, offering a solution to supply chain disruptions that often hamper military operations.

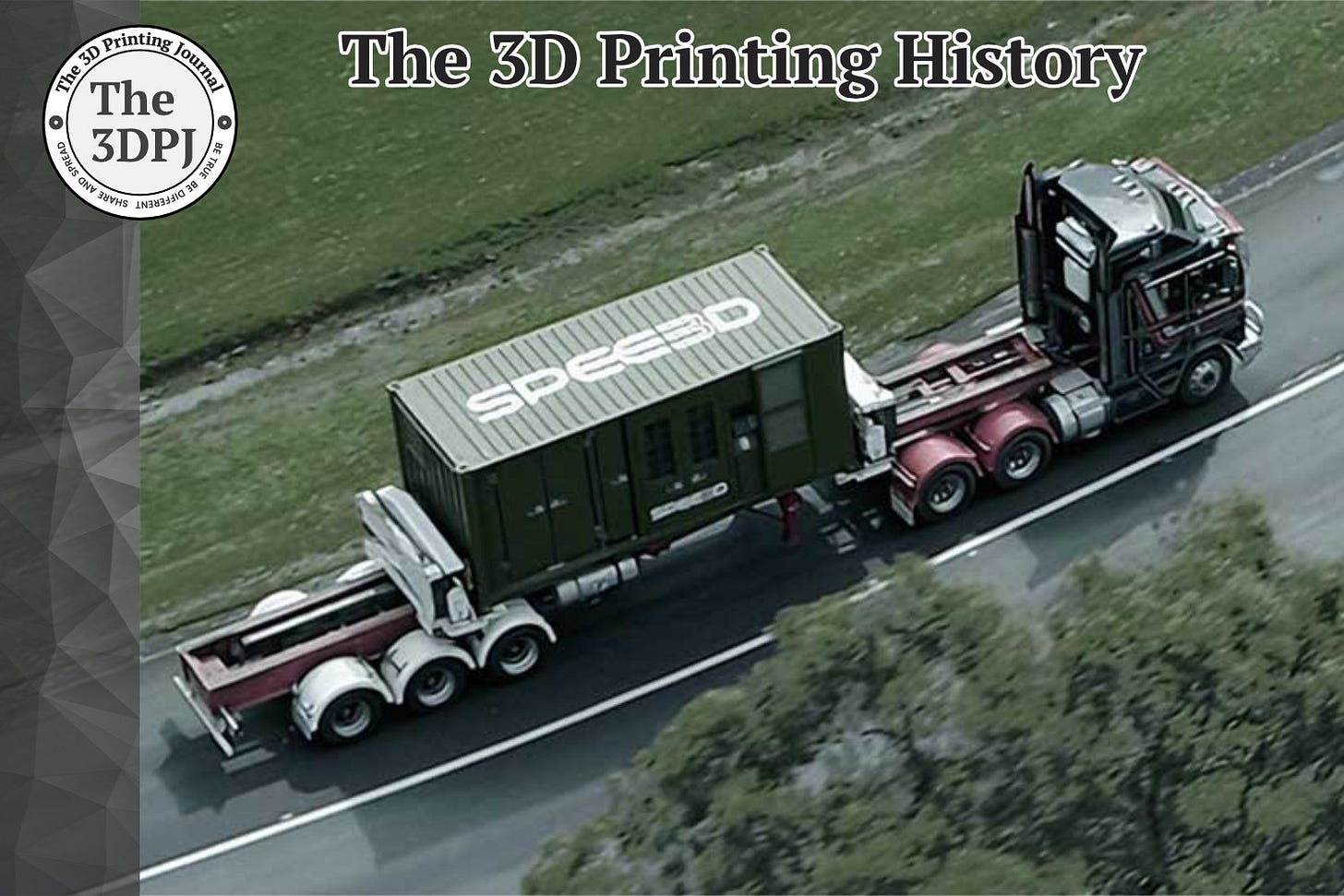

The unveiling of XSPEE3D took place following extensive collaboration with the Australian Army, where the machine was tested in rugged environments to ensure its deployability. Built within a standard 20-foot shipping container, the XSPEE3D is easy to transport and operate in remote or hostile locations. Capable of producing parts weighing up to 40 kilograms, the system enables the military to address urgent spare part needs without relying on unpredictable global supply chains.

SPEE3D’s innovation lies in its proprietary cold spray technology, which differs from conventional metal 3D printing methods. Instead of using lasers to fuse metal powders, cold spray propels particles at such high speeds that they fuse upon impact. This process not only makes printing faster but also allows for the use of materials like copper, nickel carbide, and titanium.

Founded by Byron Kennedy and Steven Camilleri, SPEE3D’s mission was to solve the challenge of producing metal parts quickly and efficiently. Prior to XSPEE3D, the company launched other models such as LightSPEE3D and WarpSPEE3D, both known for their high throughput and use in industries from aerospace to military.

SPEE3D’s work with the Australian Army helped showcase the potential of cold spray 3D printing in military applications. During testing, the WarpSPEE3D system was moved over 1,200 kilometers across rough terrain to demonstrate its durability. This paved the way for XSPEE3D’s success, providing a solution to the military’s supply chain challenges by allowing the production of spare parts on-demand in extreme conditions. The launch of XSPEE3D was a pivotal moment in both the history of SPEE3D and the future of military logistics.

Source: www.spee3d.com