10-16-2013: Arburg unveiled Freeformer

A 3D printer using granules in its proprietary AKF (Arburg Plastic Freeforming) technology

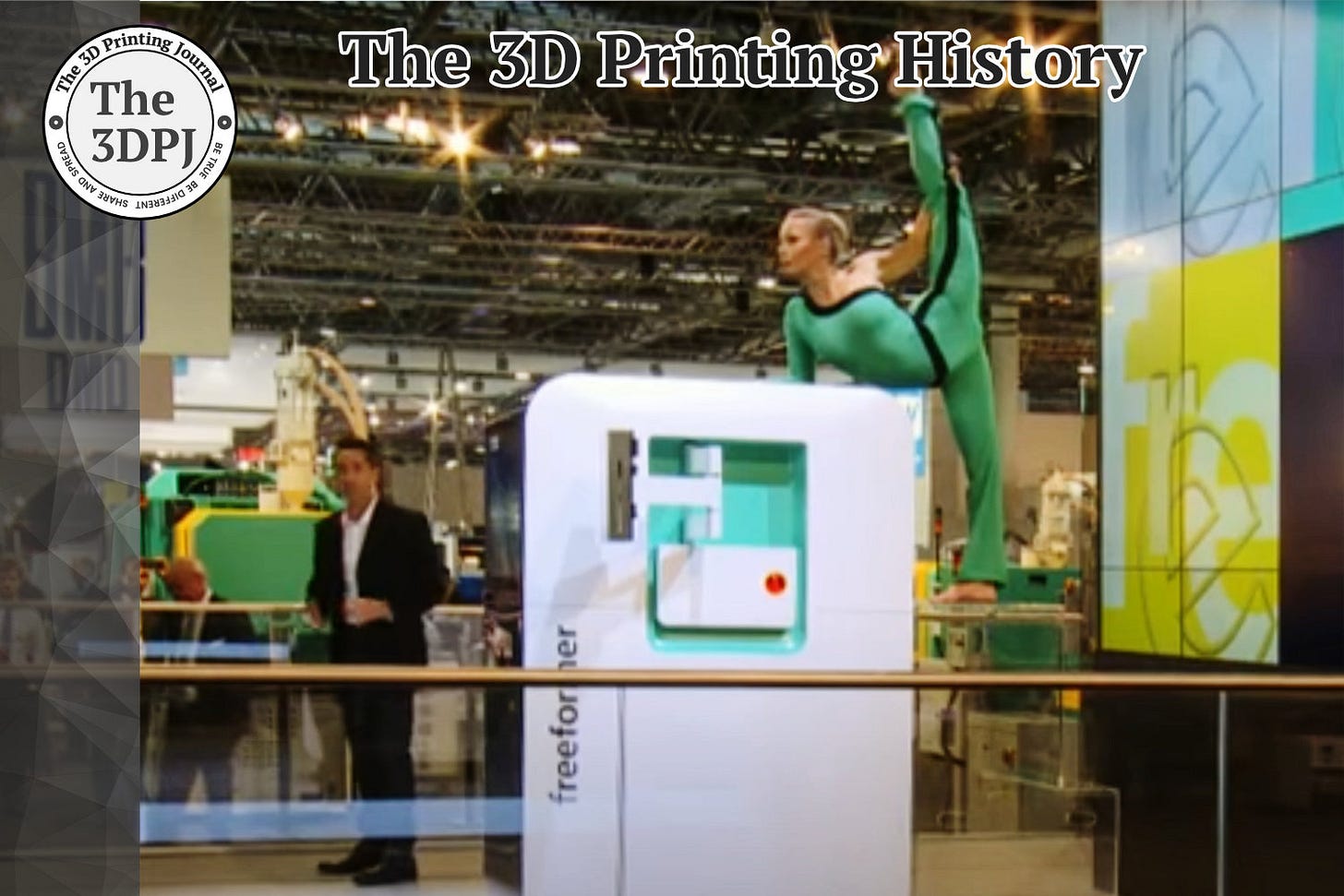

On October 16, 2013, Arburg, a German machine manufacturing company specializing in injection molding technology, unveiled its first 3D printer, Freeformer. The launch took place during the K Show in Düsseldorf. The machine used a proprietary and unique 3D printing technology called AKF (Arburg Plastic Freeforming), which enabled the use of the same granules used in injection molding machines. The Freeformer product line is still in development today, with three models: the 750-3X, 300-3X, and 200-3X.

Arburg's technology was a unique combination of additive manufacturing and injection molding. Instead of using filament, it used standard granules. Unlike other machines on the market, the melted plastic wasn't continuously extruded from the print head but was sprayed in tiny droplets that fused into a single path. This micro-droplet deposition allowed for more precise application compared to continuous extrusion methods (such as FFF).

The 3D printer's launch was spectacular, with visual effects, curtains, and a gymnast performing complex moves around and on the machine. It was as unique as Arburg's technology itself.

Initially, the company promised another innovation – a 5-axis rotating build platform to eliminate the need for support structures, but this solution never made it to market.

The the actual market debut took over a year... And when Freeformer finally arrived it did not instantly capture the market as expected. The high price (starting at €120,000) and relatively small build volume (less than 20 cm in XYZ axes) made it a very specialized solution, despite its great potential (granules!).

Source: www.3dprintingindustry.com