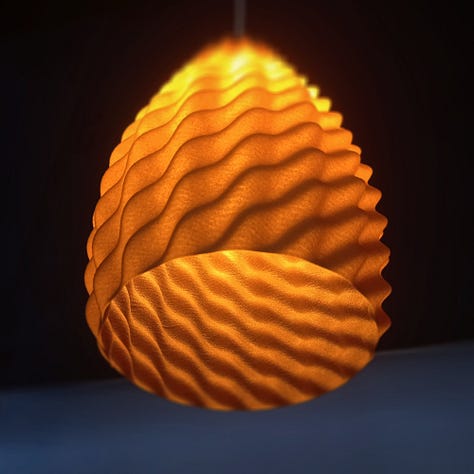

3D printed light

3DP War Journal #68

Signify opens a European 3D printing hub in Poland! Hundreds of 3D printers will produce lighting fixtures, creating 150 new jobs. Production will begin in Q1 2026 and reach full capacity by mid-next year.

The new Signify plant is being established in Piła, a city in northwestern Poland. Several hundred automated 3D printers will be installe d there to produce lighting fixtures made from recycled granulate. According to Signify, this allows for up to a 70% reduction in carbon footprint.

Additionally, 3D printing will shorten the time to market for new products from 1.5 years to just 14 weeks, offering the company tremendous flexibility.

The investment in Piła complements Signify’s existing R&D and distribution hubs, further strengthening Poland’s position as a key additive manufacturing market in Europe.

Formerly known as Philips Lighting, Signify has long held its position as a global leader in smart and energy-efficient lighting. In 2018, the company rebranded and officially separated from the Philips Group. Today, Signify manages such brands as Philips Hue, Interact, and MyCreation - the latter being entirely based on 3D printing technology.

MyCreation will be the main beneficiary of the new production center in Piła.

Around 300–400 fully automated 3D printers will be installed in the new factory. These industrial machines will operate continuously, day and night, producing lighting fixtures for markets across Europe. Signify has announced that in the first phase it will employ around 60–70 people, but the team is expected to eventually reach 150 employees.

Producing lighting accessories with 3D printers is one thing, but what’s equally intriguing is Signify’s approach to materials.

Instead of traditional injection molding or casting with virgin plastics, the Piła plant will use polycarbonate granulate derived from oil-based waste - both petrochemical and food-related.

In other words: the lamps hanging from your ceiling will be made from processed waste.

Additionally, 70% of the fixtures will be fully recyclable, and 65% of the raw materials used in their production will come from recycled or bio-based sources.

Industrial 3D printing of light

3D printing in the lighting industry is not a new concept. Several years ago, companies began experimenting with printed shades and lamp housings, mainly in the design segment.

However, it is only Signify that has managed to transform this idea into a real industrial process operating at the scale of a large factory.

According to company data, additive manufacturing technology allows the time to market to be reduced from the typical 18 months to just 14 weeks. This is a revolution - not only in production but also in how companies think about design, storage, and sales.

3D printing also enables experiments with forms that were previously impossible. A lamp can now have a structure resembling tissue, mesh, or organic patterns.

In 2023–2024, I personally experimented with 3D printing in the lighting industry. As GREENFILL3D, we created biodegradable and compostable eco-lampshades printed from proprietary filaments blended with wheat bran or potato starch.

Of course, the scale was incomparable to Signify’s, but I fully understand the immense potential in combining light and 3D printing - and how difficult it is to harness that potential in practice.

More than just a plastic lampshade

Producing such objects requires not only precise machines but also a deep understanding of the material. Every change in temperature, speed, cooling, or material composition can completely alter the final result.

Printing lamps is not just “printing plastic” - it’s the creation of delicate structures that must simultaneously transmit light, dissipate heat, and maintain aesthetics. It’s a combination of physics, chemistry, and design.

Everything suggests that 3D printing in lighting will become a standard in the coming years - perhaps not the only one, but certainly one of the key production models. For companies like Signify, it’s not only a way to lower costs and speed up production but also a real step toward a circular economy.

At the same time, 3D printing revives something the industry has long lost - a human scale.

In the additive model, you don’t produce hundreds of thousands of identical objects but exactly as many as you need. Each product can be different, unique. In this way, technology brings individuality back into the world of manufacturing.

It’s a return to craftsmanship - but in a modern, digital form.

All lampshade photos used in this article are the property of GREENFIELD & COLORISED

#7. Michael Kenworthy joined Relativity Space as Vice President, Engineering

Michael Kenworthy, one of the most prominent AM specialists in area of industrial manufacturing, has joined Relativity Space as Vice President, Engineering. Previously, Kenworthy served as Chief Product Officer at Seurat Technologies and Divergent.

Relativity Space experienced a turbulent period last year, and the company’s future seemed briefly in jeopardy. Fortunately, in January of this year, Eric Schmidt, the former CEO of Google (now Alphabet Inc.), came to the rescue and has invested in the company. Kenworthy’s joining the team seems to be proof that the company is past its worst days.

READ MORE: www.linkedin.com

#6. Zellerfeld launched 3D printed footwear hub in Texas

Zellerfeld has inaugurated its first U.S. production facility in Austin, Texas, expanding its distributed manufacturing network. The new hub will serve the American market, eliminating transatlantic shipping and tariffs. The launch coincides with the deployment of Zellerfeld’s new GEN3 3D printer. This system is three times faster, offers multi-color printing, and operates fully autonomously, enabling a shift from thousands to millions of mass-customized shoes annually.

READ MORE: www.voxelmatters.com

#5. HP and Continuum Powders partnered on high-performance 3D printing alloys

HP is partnering with Continuum Powders to develop high-performance metal alloys for its Metal Jet S100 binder jetting system. The multi-phase program will begin by characterizing Continuum’s sustainable OptiPowder M247LC, a nickel-based superalloy.

The collaboration aims to optimize process parameters to achieve part densities exceeding 98% and confirm aerospace-grade performance. This will enable the industrial-scale production of high-temperature, corrosion-resistant parts, reducing supply chain risks and accelerating production for customers.

READ MORE: www.tctmagazine.com

#4. Nanoe launched new ultra-high-temperature ceramic composite

Nanoe is expanding into the UHTC market with a new ZrB₂-SiC composite for extreme aerospace and defense conditions. The material is available as both powder for traditional manufacturing and filament for additive manufacturing.

A key innovation is the material’s formulation, which enables pressureless sintering at 2000°C. This overcomes a major industry limitation, as UHTCs typically require pressure-assisted sintering that restricts part geometry and scalability. The company states this allows for complex designs without compromising density. Early adopters include major research institutions like NASA and ONERA.

READ MORE: www.voxelmatters.com

#3. Amnovis shipped 100,000th 3D-printed implant on fifth anniversary

Belgian Amnovis is celebrating its fifth anniversary by shipping its 100,000th 3D-printed medical implant. This milestone part was an FDA-approved SI fixation system, accelerated to market using Amnovis’s own regulatory master file.

The company has established a strong reputation in regulated industries, achieving a 99.9% customer acceptance rate and over 90% on-time delivery. While focused on medical devices, Amnovis also produces parts for aerospace and semiconductor sectors.

READ MORE: www.3printr.com

#2. Caracol secured $40M in Series B

Caracol has raised $40 million in a Series B round co-led by Omnes Capital and Move Capital. The oversubscribed funding will accelerate its international expansion into the US, Middle East, and Asia-Pacific markets. The company plans to enhance its multi-material robotic manufacturing platforms, focusing on software and AI-driven process control. Caracol will also ramp up its metal additive manufacturing for aerospace and energy sectors, building on its existing global footprint of over 100 installed robotic systems.

READ MORE: www.voxelmatters.com

#1. Bambu Lab launched P2S 3D printer

Bambu Lab has launched the P2S, a complete redesign of its iconic P1 Series. The new model integrates technologies from the recent H2 Series, including the DynaSense extruder and an Active Airflow system.

It also features a 5-inch touchscreen, advanced AI error detection, and a quick-swap nozzle. Priced at just €519, the P2S aims to be an ultra-affordable and reliable foundation for print farms, combining a compact design with enhanced productivity for mass production of end-use parts.

READ MORE: www.bambulab.com

Is that filament from https://printonion.com or where can I find it?