AM companies must return to the "old-school" way of doing business

The Atomic Layers: S7E27 (00205)

Atomic Layer of the Day:

Today, I recorded another episode of my podcast, and my guest was the great John Kawola—CEO of Boston Micro Fabrication (BMF) and former CEO of Ultimaker North America and Z Corporation, among others. Another fantastic conversation—you won’t be disappointed.

One of the many topics we covered was the profitability of legacy AM companies. Because, in case you didn’t know, back in the early days—the ’90s and ’00s—companies producing 3D printers or offering 3D printing services actually made money.

If they didn’t, they went out of business. It was that simple.

Investment funds weren’t as enthusiastic about "rapid prototyping" back then as they later became about "3D printing" after 2010. The only 3D printing companies publicly traded at the time were Stratasys and 3D Systems, and they weren’t exactly raking in cash.

So, back then, the only way to be successful in this industry was to generate profit from selling products or services.

Then MakerBot and its crew arrived, promising that 3D printers would be in every home and that everyone would become a maker. 3D Systems and Stratasys also jumped on the bandwagon, and soon, money started flowing like never before. And when the money came, companies were eager to spend it.

During an off-the-record conversation with Jonathan Jaglom about MakerBot, I wondered whether the company had ever been profitable. We couldn’t find a clear answer, and getting full historical financial reports was impossible. But the question remains—did the company that created the desktop 3D printing market ever turn a profit in any given year? Maybe at least in the first one…?

When the second wave of industrial AM companies arrived—led by Desktop Metal, Carbon, and Velo3D—there was more "free money" than ever before. Burning cash became the standard way of doing business.

Now, we know how things turned out—free money is gone and won’t be coming back anytime soon. AM companies must return to the old-school approach—making money through operations, not by selling dreams of future growth.

For some, that could mean a death sentence.

Atomic Layer from the Past:

02-27-2021: the last Stratasys patent on the heated build chamber for FDM technology expired.

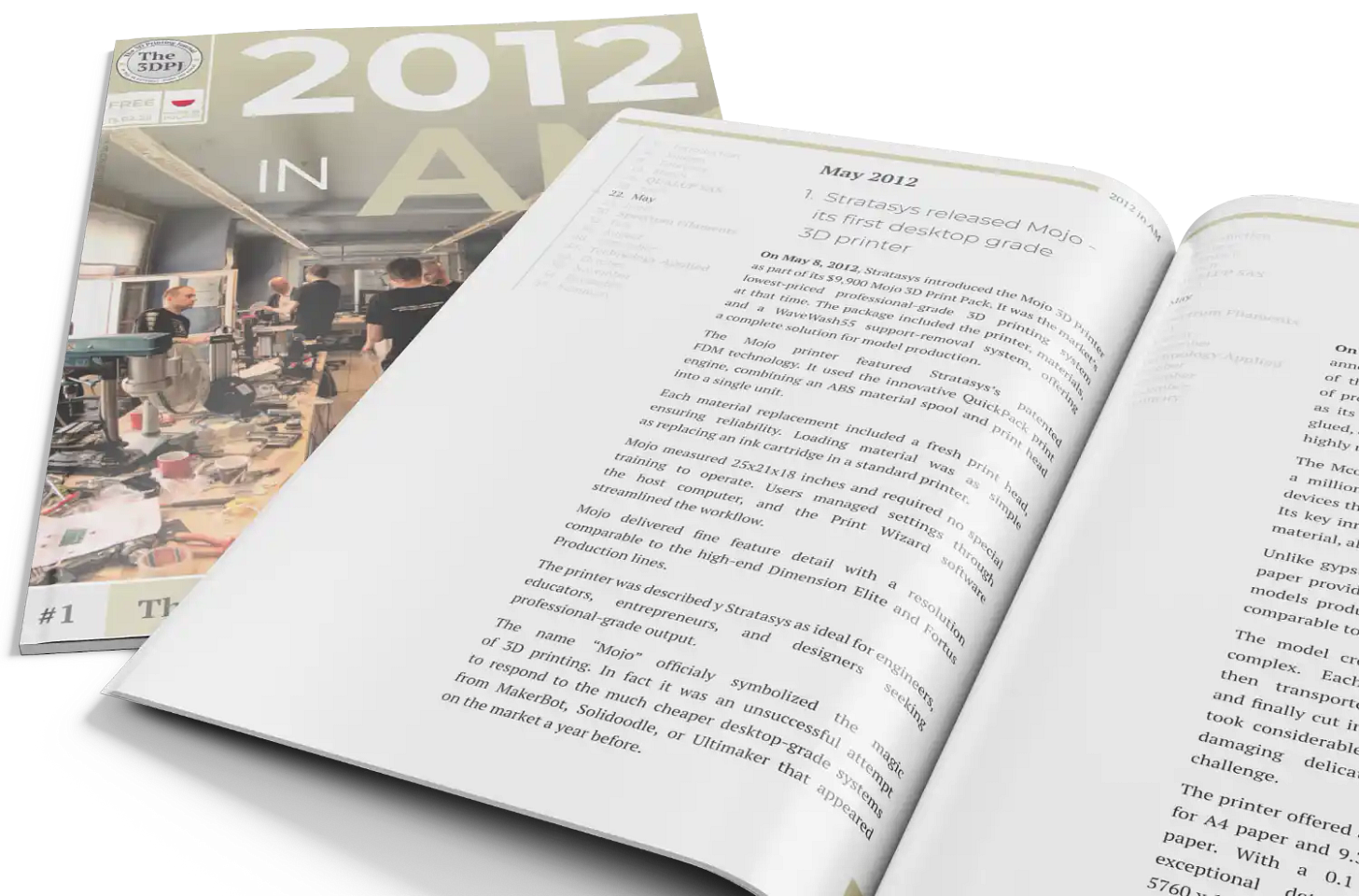

GET FREE HISTORY BOOK: ‘2012 in AM’

News & Gossip:

Bambu Lab has expanded material support in its Bambu Studio slicer. Version 1.10.2 now includes official Sunlu filament profiles, and supported materials include PETG, PLA+, and more. The update is available in Bambu Studio, with more materials expected in the future.

There has been a lot of talk lately about the incoming death of desktop FFF printers based on Cartesian kinematics (so-called bed slingers). In the meantime Sovol introduced the SV06 Plus ACE, a high-speed FDM 3D printer with Klipper firmware. It prints up to 500 mm/s with advanced vibration reduction for better quality. Featuring a 300 × 300 × 350 mm build volume, 300°C hotend, WiFi, LAN, USB, and remote monitoring, it’s priced at $299.

And finally, I highly recommend watching this video by Erik Patak, where he showcases his unique business—creating miniature machines using 3D printing. The miniatures are somewhat functional—you can open them, light them up, or remove certain parts. They are designed for events, conferences, or client demonstrations. Overall, it’s a fascinating and highly practical idea. You can find more photos here.