Bambu Lab integrates Helio Additive’s sophisticated simulation tool

RECODE.AM #11

Bambu Lab and Helio Additive have announced a partnership that opens up entirely new areas of application for the Chinese manufacturer’s 3D printers.

The integration of Dragon — Helio’s simulation engine — directly into the BambuStudio software means that Bambu printer users (particularly those with H- and X-series models) gain access to industrial-grade thermal simulation and print process optimization without having to switch slicers or install additional hardware.

What exactly does this integration do, and what are the benefits?

Helio Additive has developed a voxel-based simulation approach, in which the printing process is modeled “step-by-step” at the level of small volumetric elements.

The Dragon engine tracks heat exchange between neighboring voxels, predicts local temperature changes, estimates the risk of insufficient layer adhesion or local overheating, and can pinpoint parts of the model prone to deformation or reduced strength.

This allows the operator — before launching the physical print — to receive a “Thermal Index” of the model: a visual overlay showing areas that are too cold, optimal, or too hot, along with recommendations for settings (speed, temperature, interlayer time).

In practice, tests and initial comparisons show a significant advantage for parts printed after Helio optimization compared to default settings: better layer bonding, less deformation, and often the possibility of faster printing while maintaining quality.

Who is Helio Additive?

Helio Additive brings tangible experience and expertise in materials and processes. The company’s founder and CEO is David Hartmann — a specialist with long-standing experience in the materials industry and technology management.

Before founding Helio, Hartmann spent many years in corporations related to materials and chemicals (including Bayer/Covestro), working on strategy, mergers, and business development. This background gave him a deep understanding of how materials behave in production conditions and the importance of modeling the physics of the process.

In numerous interviews, Hartmann has emphasized that the goal of Dragon is “first-time-right” printing — reducing trial and error, minimizing material waste, and making production processes more predictable.

Helio built Dragon as a set of simulation and optimization tools for additive manufacturing, initially focusing on large industrial systems where thermal differences and process scale are critical.

Since showcasing its technology at industry trade shows, the company has been expanding both its material database and its API toolkit, enabling integration with various slicers and OEMs.

Helio’s offering also includes developer tools and process dashboards to help manage simulations, track print parameters, and compare results.

Helio operates on a cloud-based model: the user uploads G-code or print metadata, the engine performs the simulation, and returns the results with a thermal overlay and possible optimization recommendations.

Integration with Bambu Studio

Technically, integration in BambuStudio works as follows: the user enables the Helio option in the program settings, generating a Personal Access Token (PAT), which allows the G-code file to be sent for simulation.

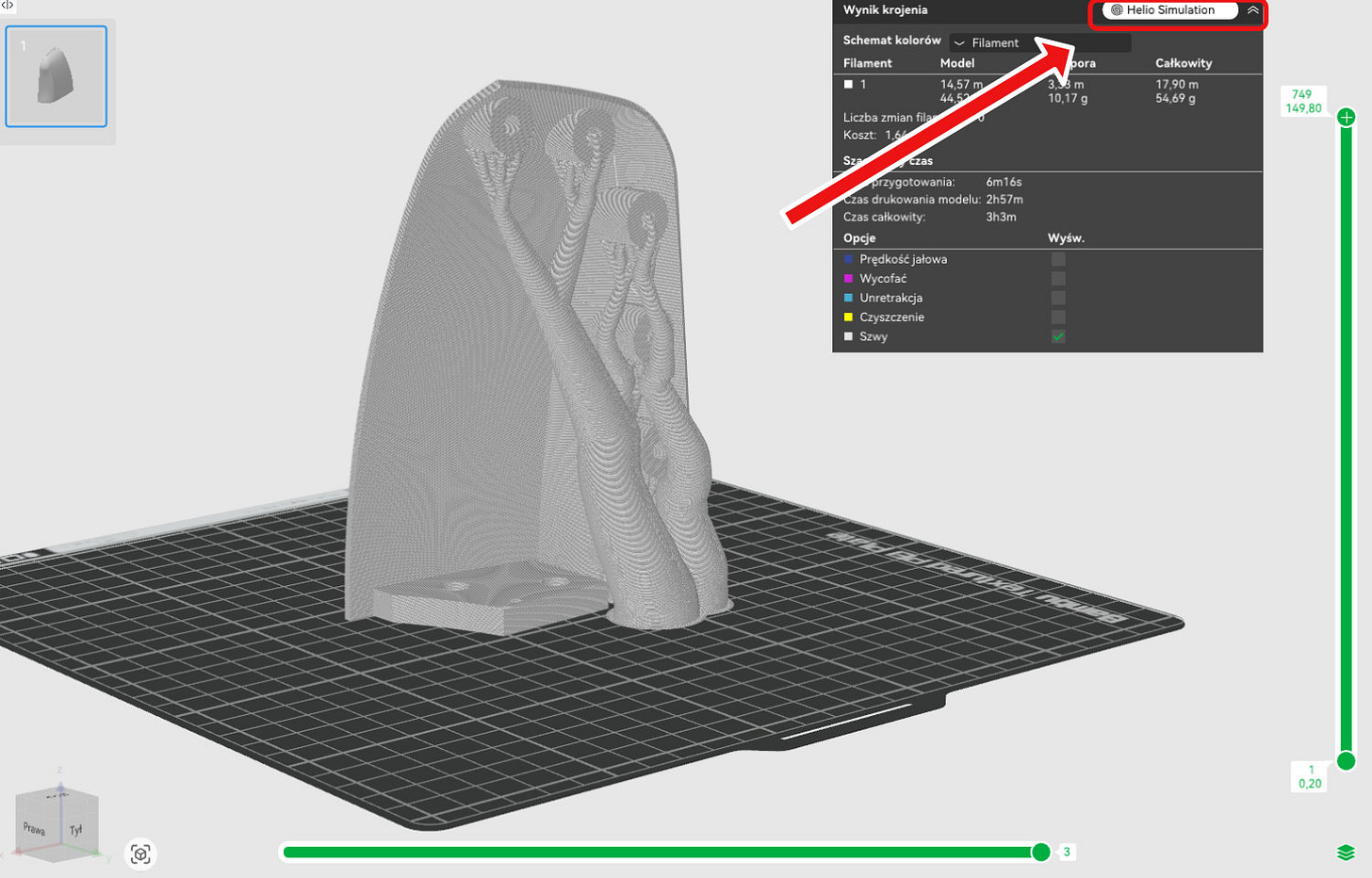

After completing the regular slicing process, a “Helio Action” button appears in BambuStudio, launching the simulation. The user enters an approximate chamber temperature and observes the simulation progress bar.

Once the process finishes, the previously mentioned Thermal Index is displayed, with the option to preview details layer by layer.

In the beta phase, the integration supports specific Bambu printer models (including X1C, X1E, and H2D) and a selected set of filaments. However, there are some limitations — no support yet for multi-material or multi-color printing.

Using Helio’s solutions is not entirely free — all BambuStudio users on H-series and X-series printers receive 25 free simulations per month. For more demanding use cases, users can upgrade to a $15/month subscription managed directly by Helio Additive.

Bambu Lab moves toward more professional users

Finally, it’s worth placing this news in the broader strategic context of Bambu Lab.

Contrary to popular belief, Bambu Lab’s 3D printers were not initially intended to be engineering or industrial devices. The company positioned itself from the start as a manufacturer of consumer devices aimed at home users.

Of course, everyone at Bambu Lab was aware that their printers were being used by professionals in serious industries. It’s just that — apart from the X1E model — there were no dedicated, targeted initiatives in this direction.

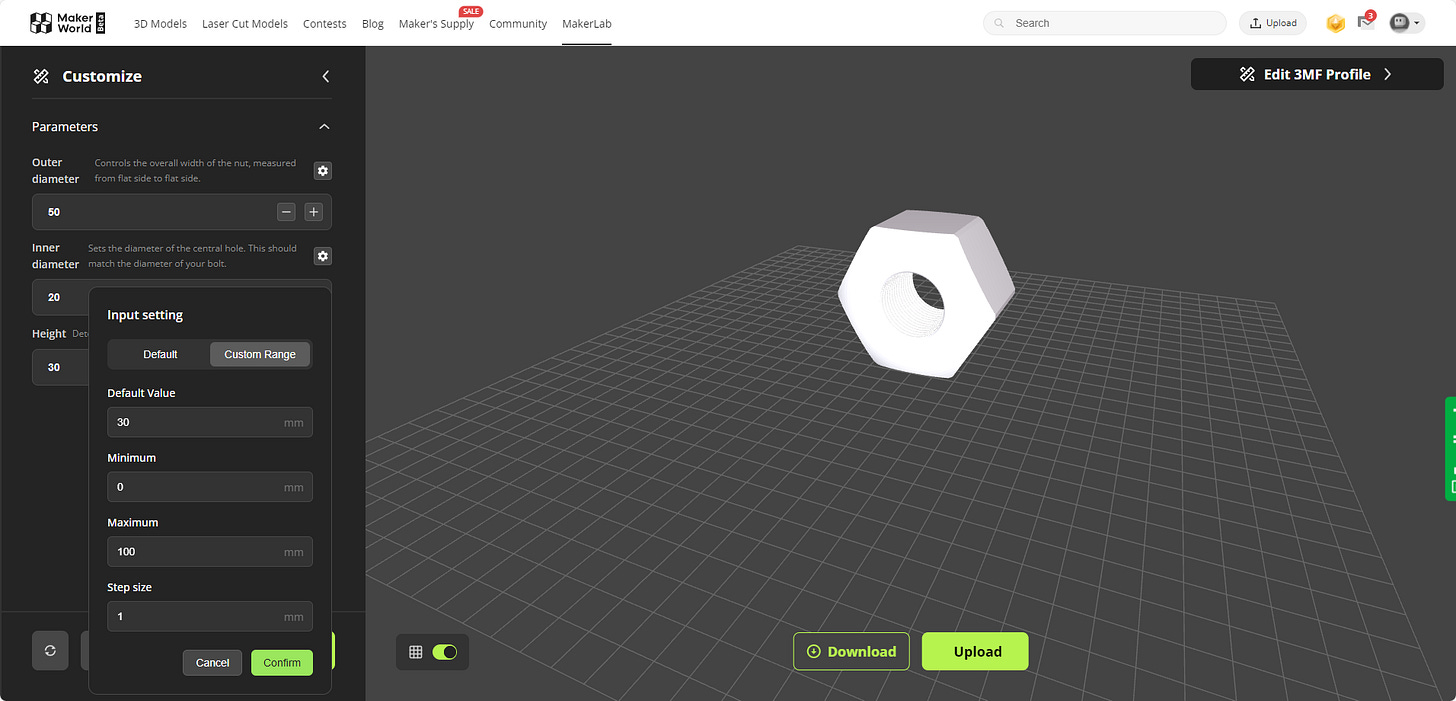

But now, this is slowly changing. Examples include not only the cooperation with Helio Additive, but also the launch of the new H2D Pro 3D printer — clearly targeted at businesses — and last month’s announcement of the integration of the Parametric Model Maker in MakerWorld, Bambu Lab’s 3D model platform, with Autodesk Fusion 360.

Does this mean a shift in strategy and a focus on industrial solutions?

Absolutely not. The consumer market remains the core business and identity of the company.

It’s just that professional users are now getting completely new tools and capabilities compared to before. And there’s more exciting stuff to come…

Quick cheat sheet - how to enable and use Helio in Bambu Studio:

In BambuStudio, go to Preferences → Helio Options, enable Helio, and generate your PAT.

Slice your model as usual, then click the “Helio Action” button to send the G-code for simulation.

Enter a realistic chamber temperature, wait for the simulation to complete, and review the Thermal Index overlay:

Values close to 0 = optimal conditions.

Negative values = risk of poor layer adhesion (increase nozzle temperature, reduce speed, or increase interlayer time).

Positive values = risk of overheating and deformation (lower temperature, increase cooling, or shorten heating time).

After adjustments, re-slice and re-run the simulation until you achieve a satisfactory thermal distribution.

Keep in mind: the current integration works via the cloud (PAT is used for authorization), supports selected Bambu models (X1C, X1E, H2D) and specific filaments, does not yet handle multi-material prints or fully automated G-code optimization. The free token limit and subscription plans may change — if your company has file security policies, check with your IT department before uploading G-code.

My notifications from Bambu Lab and/or Formlabs: "Hey, here's new functionality, material, or upgrades an low or no-cost!"

My notifications from Stratasys: "Hey, here's another price increase for the same materials, parts, or services!"

Amazing solution and very well explained. I hold the reading of your column so I was not "inspired" (subconstiouns copying), and now I see you made a way better explained material. That aside, it is great to see professionals tools such this arriving in the Bambu environment.