Full-color revolution

3DP War Journal #61

The past week may go down in history as a breakthrough moment in the development of full-color FFF 3D printing technology.

Snapmaker, with its new U1 printer equipped with an affordable toolchanger, raised such an enormous amount on Kickstarter ($14 million at the time of writing) that the campaign entered the top five most funded projects in the platform’s history.

At the same time, Bambu Lab surprised the market by announcing the Vortek system – a completely new approach to multicolor 3D printing, based on swapping hotends instead of filament. The company did this barely an hour after the launch of its long-awaited single-extruder 3D printer, the H2S.

Just a few hours after Bambu Lab’s reveal, Prusa Research also teased a new full-color printing system based on Bondtech’s INDX, suggesting that the company had no intention of ceding ground to its competitors.

These events are part of a long history of attempts to develop solutions that would make multicolor FFF printing practical, affordable, and, most importantly, free from the drawbacks of material waste.

And this story is already 13 years old!

Color mixing and the first major hoax in desktop FFF 3D printing

The first attempts at multicolor printing appeared long before Bambu’s AMS or Prusa’s MMU reached the market. As early as 2012, the RepRap community was buzzing about experiments by RichRap, who developed the concept of hotends capable of mixing several filaments inside a single nozzle.

It was not yet a path to full CMYK, but the idea of gradients and smooth color transitions attracted significant attention among hobbyists.

The next chapter in this story was the loud and controversial case of botObjects. In April 2013, the startup founded by Mike Duma and Martin Warner announced the launch of ProDesk3D – the first consumer FFF printer allegedly capable of full-color printing.

The machine was supposed to use five PLA cartridges in a CMYKW system and mix colors in real time inside the nozzle.

The announcements also included a dual-extruder head with soluble supports, auto-calibration, an anodized aluminum casing, and 25-micron resolution. This sparked enormous media enthusiasm, but also a wave of skepticism. The lack of evidence of working prototypes, vague information about the engineering team, and a secretive pre-order policy raised growing doubts.

Only in 2014 did the company release a video showing a gradient print, which partially confirmed the existence of the technology but did not dispel suspicions. The story ended in January 2015, when botObjects was acquired by 3D Systems.

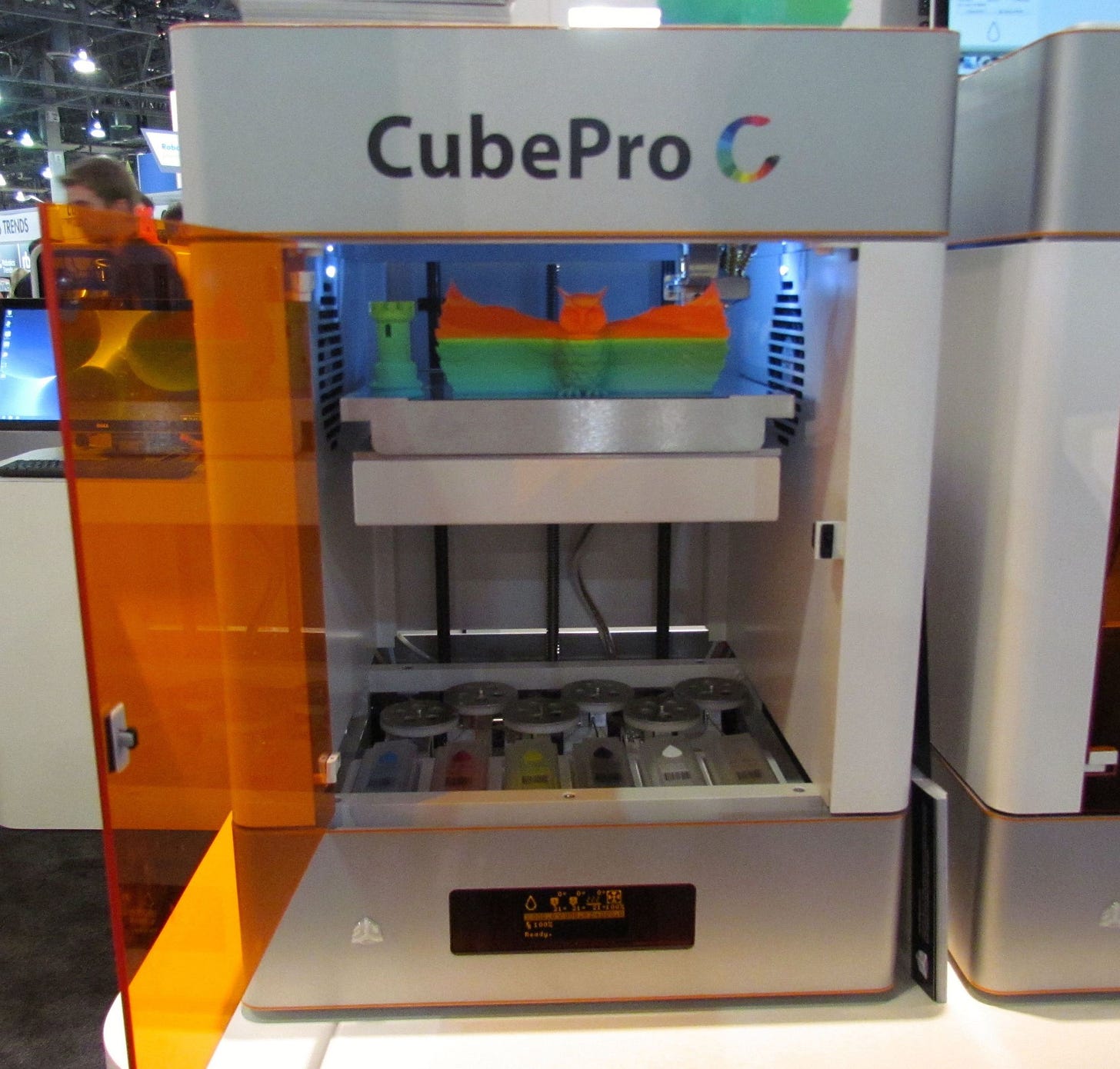

As a result, the CubePro C appeared on the market, actually using the five-cartridge concept but not offering true, unrestricted full-color printing.

Just a few months later, following management changes at 3D Systems, the entire consumer line was shut down, and the CubePro C went down in history as a major unfulfilled promise.

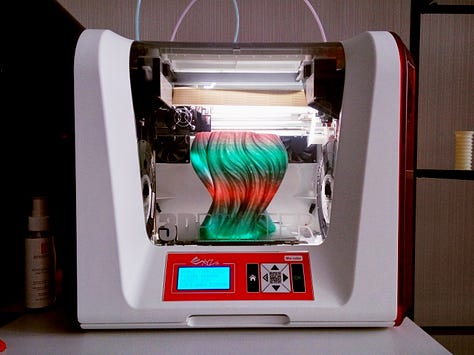

The idea was briefly revisited by Taiwan’s XYZPrinting, which presented the da Vinci Junior 2.0 MIX.

Despite its intriguing functionality and unusually low price for 2017, it failed to gain popularity, and the concept of filament mixing in a single nozzle was consigned to the annals of history.

Full color on the layers – XYZprinting, Rize3D, and OVE

Parallel to filament-mixing systems, a second path was being developed – attempts at true CMYK full-color printing, similar to inkjet technology.

In 2017, Taiwan-based XYZPrinting showcased the da Vinci Color – a 3D printer that applied CMYK ink onto filament during printing. It was the first widely available model to offer photorealistic colors, albeit with limitations: it required special PLA filament, struggled with coating spherical surfaces, and printed relatively slowly.

It was the first – and only – fully commercialized attempt to combine filament-based 3D printing with inkjet technology.

At the same time as XYZPrinting, two other companies, from very different corners of the world, were working on similar solutions.

The American company Rize3D developed APD technology, which combined thermoplastic filament extrusion with an inkjet head applying both colored and functional inks (CMYK) onto the printed parts. An additional release agent ink allowed supports to be removed easily, without the need for finishing work.

Meanwhile, in Poland, the company OVE presented its solution based on Memjet technology. Each layer of the print was coated with ink in a single fast pass of the printhead, producing fully uniform coverage.

The A4-format machine, with a 300 mm build height, was intended for industrial applications and priced at around €10,000. Although it never reached the mass market, it remained the only European attempt to create a system combining FFF with inkjet-based full-color 3D printing.

From Palette to AMS – the road to full color through waste

In 2016, the Canadian startup Mosaic introduced the Palette device, which “welded” segments of different filaments into a single strand, synchronized with a 3D model. This allowed virtually any FFF printer to print in four colors.

It was a clever solution, but burdened with a typical problem – each filament change required nozzle cleaning and generated waste in the form of a so-called or purge blocks.

Soon after, Prusa Research launched its Multi Material Unit (MMU), which enabled feeding five filaments into a single nozzle.

The first generation was difficult to use and discouraged many users, but subsequent iterations improved reliability, leading up to the MMU3, which today is a relatively stable solution.

A similar technology was developed by Bambu Lab, which in 2022 unveiled AMS – an intelligent multi-filament feeding system. AMS was the first mass-market solution to gain huge popularity, selling in the hundreds of thousands and making multicolor printing a real option for thousands of users.

This success fueled a boom in multicolor 3D models. However, the fundamental problem remained – with frequent color changes, waste could far exceed the weight of the actual print.

Toolchangers and the new “zero-waste” era

Meanwhile, a fourth path was maturing – toolchangers. The concept of swapping entire toolheads was introduced by E3D in 2019, but the high cost and mechanical complexity prevented it from gaining traction.

The idea was later adopted by Prusa Research, which released the Prusa XL with the option to install up to five independent tools. The toolchanger solved the biggest problem of AMS and MMU systems – there was no need to purge the nozzle with every filament change, since each head worked only with its own filament.

The printer gained significant attention, but the very high cost of a fully equipped system kept it a relatively niche solution.

The breakthrough only came in 2025. First, the Chinese startup WonderMaker launched the ZR Ultra on Kickstarter, raising about $0.8M in May. In July, Snapmaker unveiled a nearly identical device called the U1 and launched its Kickstarter campaign in August.

The success exceeded expectations: customers rushed to back it, and within a week the campaign reached the TOP 5 most funded in Kickstarter history. The message was clear – users want multicolor printing, but they don’t want to pay for it with wasted filament.

And then Bambu Lab stepped in, introducing Vortek – a system for swapping hotends instead of entire extruders. This was an even more radical idea: lightweight, swappable modules with onboard electronics and wireless communication, designed to eliminate waste and enable fast material changes.

The company announced that 3D printers equipped with Vortek, branded as H2C, would ship to customers before the end of the year – a move that could completely shift the balance of power in the industry.

Meanwhile, Bondtech also entered the scene, announcing its INDX system – passive, low-cost tools with inductive heating, likely to appear in future generations of the Prusa CoreONE.

Are toolchangers a revolution?

Let me start this way: “I wish I could tell you more...”

Earlier this year, I saw a video recorded in 2012 in the R&D department of a very large corporation that once operated in the AM market (I’m writing in the past tense to obscure the source of the video). It showed an FFF 3D printer equipped with a toolchanger (three extruders). My contact told me the department heads considered the solution not groundbreaking enough, and the project was abandoned.

The printer I saw in the video did not differ structurally from what we know today. At the same time, MakerBot Replicators and wooden-framed Ultimakers dominated the market. Shocking, but true.

So the question of whether toolchangers are the long-awaited revolution is a little late. Technically, this revolution has existed for quite some time – only now has someone decided to seriously commercialize it.

Experiences with AMS and MMU showed that multicolor FFF is possible, but comes at the cost of massive material waste. In projects requiring many switches, the waste volume could be several times greater than the model itself.

Toolchangers – in the form of the Prusa XL, Snapmaker U1, WonderMaker, or ultimately Bambu Lab’s Vortek – eliminate this problem almost entirely. Each toolhead prints only with its own filament, so there’s no need to generate purge towers.

This translates into lower total cost, higher surface quality, and the ability to use materials that cannot tolerate contamination.

But is it truly a revolution? From a market perspective – the coming months will show whether users will abandon AMS and MMU en masse in favor of toolchangers.

Pricing will be a key factor: if the cost of entry for a toolchanger drops to the level of popular AMS-equipped printers, the difference in operating efficiency could convince the mainstream audience.

Who will win the race?

The history of full-color FFF printing is a story of big promises, painful disappointments, and unexpected successes. From RichRap’s experiments in 2012, through the controversial botObjects, the innovative yet imperfect approaches of XYZprinting and OVE, to the spectacular success of AMS and today’s pivot to toolchangers – it’s clear how long the market has matured to reach the point we’re at now.

Who will ultimately win this race? Snapmaker has proven that customers want affordable toolchangers and are willing to pay upfront to get them. Bambu Lab, with Vortek, may introduce a new standard that completely eliminates waste and defines the future of multimaterial printing.

Prusa stands at a crossroads – on one hand, it has a loyal community and deep experience, but on the other, it must quickly decide whether to keep developing MMU or move toward zero-waste toolheads.

And in the background remain Creality and Elegoo, who have yet to show their hand.

One thing is certain: full-color FFF printing, which for years was only a promise and a dream, is now becoming a real standard.

And 2025 will go down in history as the year this technology moved beyond experiments and prototypes to become a real tool in the hands of thousands of users worldwide.

#7. Air Force awarded 3D Systems another $7.65M contract

In September 2023, 3D Systems secured an initial $11 million U.S. Air Force contract to develop a large-format metal 3D printer for hypersonic applications. The company has now received a further $7.65 million to begin the project's second phase. Following this news, 3D Systems' stock jumped 25% intraday, with Velo3D shares also rising 19% amid new DoD contract announcements. This reflects the Pentagon's sustained investment in hypersonic tech, including a successful missile test in late 2024, positioning the DoD as a key demand driver for the additive manufacturing industry.

READ MORE: www.3dprint.com

#6. Addireen launched ADDIREEN 400G metal 3D printer with four green lasers

Chinese firm Addireen has launched the ADDIREEN 400G, a large-format metal 3D printer. It features four synchronized green lasers and a 400 mm³ build volume, specifically engineered to process highly reflective pure copper and its alloys. The machine enables high-precision, maintenance-free continuous production for industries like aerospace and electronics. Key advantages include dramatically reduced build times, 99.8% part density, and the ability to create intricate structures with wall thicknesses as fine as 0.08 mm.

READ MORE: www.voxelmatters.com

#5. IperionX received $12.5 Million from the DoD

IperionX has received $12.5 million from the U.S. DoD as part of a larger $47.1 million agreement to scale domestic titanium production in Virginia. The funding aims to secure a U.S. titanium supply chain, critical for defense and 3D printing, reducing reliance on foreign sources. IperionX will use the investment to acquire equipment, targeting an annual capacity of over 1,000 metric tons. This initiative supports the production of more affordable and sustainable titanium powder for both additive and traditional manufacturing.

READ MORE: www.3dprint.com

#4. Sandvik launched Osprey MAR 55 tool steel powder

Sandvik has launched Osprey MAR 55, a new patent-pending tool steel powder for additive manufacturing. It bridges the gap between maraging and tool steels, offering excellent weldability, high wear resistance, and a hardness exceeding 50 HRC without requiring complex heat treatments. The material also provides a sustainability benefit, reducing embedded CO2 by 21% compared to standard maraging steels. It is optimized for LPBF and DED processes and is targeted for demanding tooling applications in sectors like aerospace and defense.

READ MORE: www.voxelmatters.com

#3. restor3d raised $104m in funding

Medical device company restor3d has secured $104 million in a funding round. Private investment firm Partners Group led the investment with $65 million for a significant minority stake, while existing shareholders contributed $39 million. The company utilizes AI-driven software and in-house 3D printing to create patient-specific orthopedic implants. The new capital will accelerate product innovation and commercial growth, expanding access to personalized surgical care. A representative from Partners Group will join restor3d's board of directors.

READ MORE: www.tctmagazine.com

#2. Bambu Lab released H2S 3D printer

Bambu Lab has launched the H2S, its new flagship FDM 3D printer. Priced from $1,249, it features a 340x320x340 mm build volume, which is 220% larger than the company's X1C model. The H2S is compatible with a 10W laser engraving and cutting module, positioning it as a versatile "Personal Manufacturing Hub." It boasts a high printing speed of 1000 mm/s, a 350°C nozzle temperature, and advanced features like HEPA filtration. Targeted at both hobbyists and professionals, it offers a streamlined alternative to more complex dual-extruder systems.

READ MORE: www.all3dp.com

#1. Bambu Lab announced the new Vortek hotend change system

Bambu Lab has announced the development of the H2C, a revolutionary 3D printer featuring the new Vortek wireless hotend swapping system. This technology eliminates filament waste ("poop") by allowing the printer to automatically change entire hotends for each color, instead of purging. The compact, 10-gram hotend uses induction heating and wireless communication for reliability. Targeted for a late 2025 release, an upgrade path for existing H2D and H2S owners will be available, though it will require technical skill. This innovation aims to transform multi-color 3D printing by combining speed with minimal material waste.

READ MORE: www.voxelmatters.com

As always Pawel, great summary and interesting insights. 👍