It’s unbelievable how much has changed in just two years…

The Atomic Layers: 00303

Atomic Layer of the Week:

As some of you probably know, in 2023 I completely stepped away from the 3D printing industry and started exploring the local interior finishing market.

It was a time of total loss of my senses. I was working in the stretch ceiling sector and later expanded into eco-lampshades and exclusive Art Nouveau - style furniture.

Madness. Complete recklessness. For those who don’t know what this is about, I described that whole story here…

In any case, in mid-2024 I returned to normality and continued my interrupted career as a journalist, consultant, and analyst in the AM sector.

Nevertheless, this week I visited an old friend from that period - a co-owner of a company producing aluminum profiles for residential construction, distributor of LED lighting, and a whole range of other tools and accessories needed to install those stretch ceilings.

There were three reasons for my visit.

First, a very simple one: we hadn’t seen each other in a long time and wanted to catch up.

Second, because the company recently moved close to where I live, so it was a good opportunity to see their new headquarters.

Third, my friend needed my consultation in the area of 3D printing.

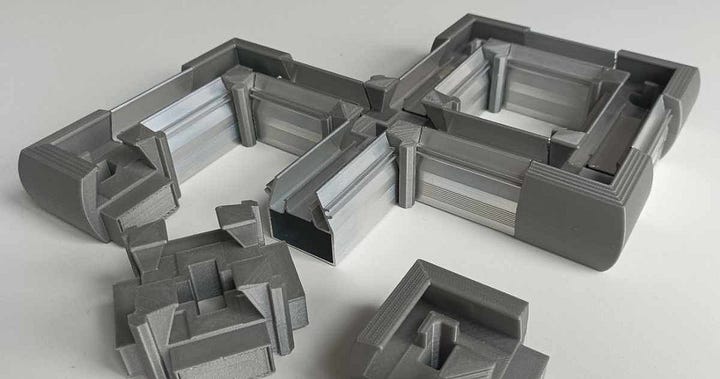

I should add that although I left the 3D printing industry in 2023, I never abandoned the technology itself or the printers. Quite the opposite - we designed and printed many of our own original projects, from lampshades and mounting accessories to specialized tools.

At the time, they enjoyed moderate interest. Yes, people bought them, but not at a scale that would allow us to sustain a company and its employees.

Meanwhile, it turned out that at after two years, some of our solutions did catch on!

One company, for example, started producing its own proprietary versions of our aluminum profile connectors. And, just like us, they use 3D printers to do it.

My friend decided to return to the topic - and meet with me to talk it through.

Of course, he knew Bambu Lab brand very well, but he didn’t know that I work with them. So at first he thought about outsourcing the production of those corner parts to me – which, obviously, was no longer possible.

After a short introduction of who I am now and what I do, I started convincing him not to outsource the production of these components, but to handle it in-house. No, not because I get a commission from selling Bambu Lab 3D printers (because I don’t), but because, considering the expected scale of the business and the final price of the product, it was simply the best and cheapest solution.

And during that conversation, both of us - my friend and I - realized just how much had changed in the 3D printing industry since the time we worked together.

And it had been barely a year and a half. Well, not even two years.

The prices of 3D printers have dropped. Or rather - the quality of what you get for roughly the same money as in 2023 has increased dramatically.

Filament prices have fallen dramatically. We used to buy them at very large discounts from our friendly manufacturers for €12–13 per kilogram, whereas today that is essentially the standard retail price. On promotion you can get them much cheaper, and in bulk even more so.

Operating 3D printers has become trivially simple. No training or onboarding is needed. You just turn them on and they work.

We were printing our parts on three Bambu Lab P1P machines (which had barely just debuted on the market) and on a fleet of heavily modified Creality Ender 3 MAX printers (anyone who owned them knows the pain).

Today, if you want to build a 3D printer farm with 100 machines, all you really need is money… and a hundred electrical outlets.

You don’t need a large workforce, specialized software, or a maintenance department. When we had around 70 3D printers, we were always servicing about ten of them at any given time…

My friend listened, asked questions, and still couldn’t quite believe it.

Two years ago he used to visit us often and saw how everything worked, how we operated, and what the quality of selected parts looked like.

And I kept explaining to him that all of that is already prehistory. That today, things are completely different.

He ordered his first P2S with AMS. We’ll see what happens next. We’ll see how many units he gets to by the end of the year…

Atomic Layer from the Past:

Two years ago, Synopsys announced a $35 billion acquisition of simulation software leader Ansys. The merger aimed to integrate electronics design with physics simulation, expanding Synopsys into automotive, aerospace, and industrial sectors.

The EU granted conditional approval, requiring Synopsys to divest its optical/photonics software and Ansys to sell its PowerArtist tool. The deal also transfered Ansys’s suite of CAD and process simulation tools for additive manufacturing to Synopsys, impacting the 3D printing software market.

Read all:

News & Gossip:

#1

In May last year, AMETEK Inc. acquired FARO, a renowned manufacturer of large-format 3D scanners. The company has now decided to realign both FARO and Creaform - another established company, which was part of AMETEK for over a decade.

As a result both 3D metrology units have been merged into a new business unit, FARO Creaform. This restructuring aims to establish clearer responsibilities and better-integrated workflows, linking measurement data more closely with industrial and additive manufacturing processes.

More on: www.3druck.com

#2

3D Systems is expanding its Littleton, Colorado Aerospace & Defense Center of Excellence by adding 80,000 square feet. The facility, selected for certification under the America Makes JAQS-SQ framework, will focus on accelerating the qualification and deployment of AM parts for defense. This move aligns with a U.S. Air Force-sponsored program for next-gen metal 3D printing. The company forecasts over 15% growth for its A&D business in 2025, driven by demand for qualified, scalable solutions.

Yes, American AM companies must love Donald Trump!

More on: www.tctmagazine.com

#3

Sounds a bit controversial? So how about this: Velo3D has entered a Cooperative R&D Agreement with the U.S. Army’s DEVCOM Ground Vehicle Systems Center (GVSC) to address supply chain challenges. The collaboration will leverage Velo3D’s Rapid Production Solution to rapidly develop and qualify additively manufactured, complex parts and assemblies for ground combat vehicles.

The work will explore qualified alloys and utilize large-format 3D printing to prototype alternatives to traditional manufacturing. Upon qualification, these parts will be available to the U.S. Army’s supply chain, aiming to enhance resilience, reliability, and surge capacity.

More on: www.tctmagazine.com

#4

Voxeljet is seriously reactivated itself, and announced developing the VX7000, a new large-format binder jet 3D printer for industrial production. The system features a massive build volume of 7000 x 7000 x 1000 mm, capable of processing over 60 tons of sand per job.

More on: www.voxelmatters.com

#5

Replique has expanded its collaboration with Alstom to become a global supplier for projects worldwide, including in Singapore, Brazil, and Europe. Initially providing 3D-printed door stoppers and tank caps, the partnership now produces parts in the lower five-digit volume range, using materials from stainless steel to flame-retardant plastics. Successful applications include replacement impellers in Asia and casting molds in Italy.

#6

And finally - a report from China’s National Bureau of Statistics indicates that the country’s output of 3D printing equipment surged by +100.5% in the past year. Obviously, I can’t say who’s mainly responsible for this growth, but I’m sure you already know… 😏

More on: www.stats.gov.cn via Fabbaloo.com