O Nano Dimension, whither goest thou?

3DP War Journal #63

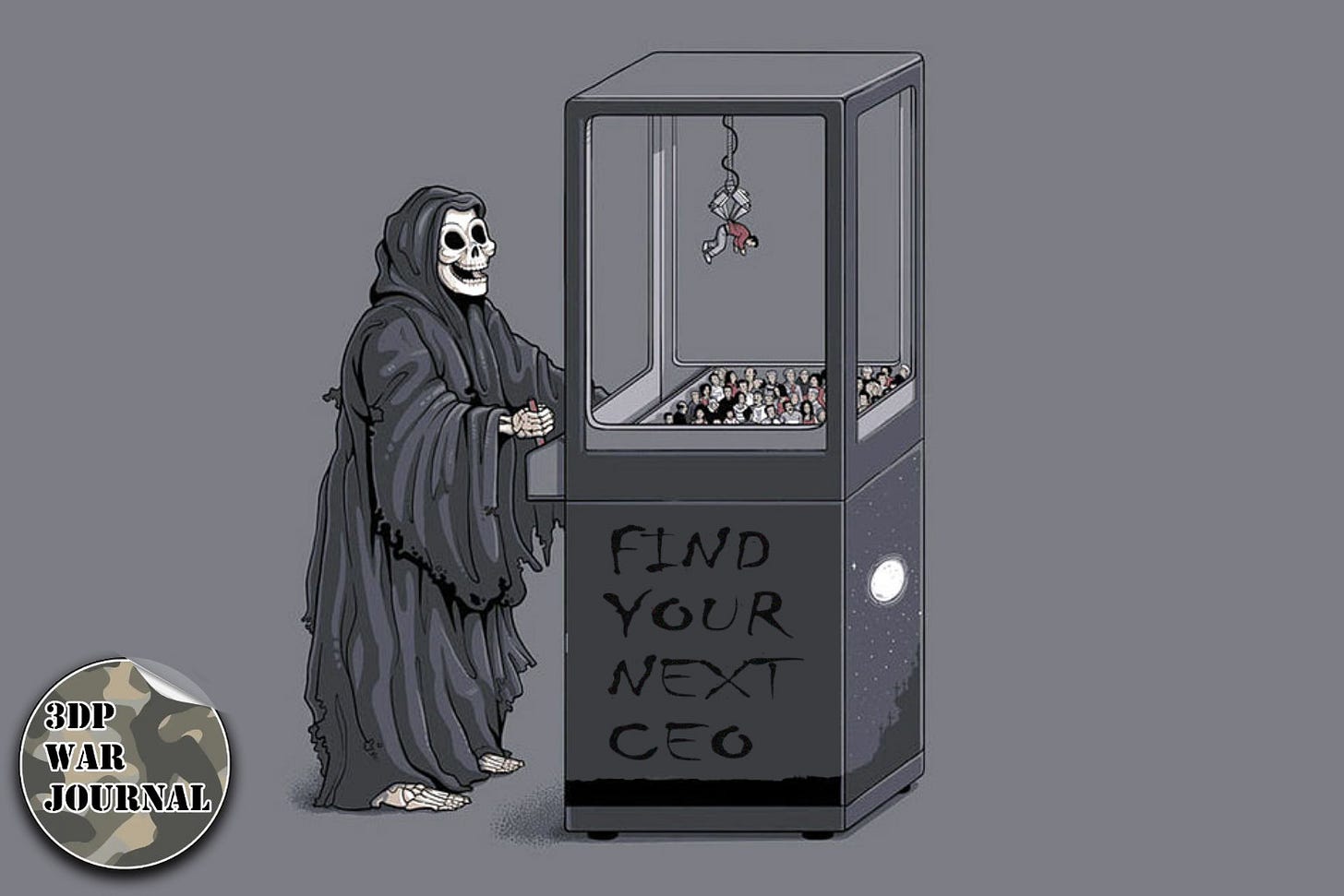

More changes at Nano Dimension! Dave Stehlin has been announced as the company’s new CEO. One might want to congratulate him, if not for one small detail… He’s the fourth CEO in just 257 days [SIC!].

Yes, my friends, the CEO chair at Nano Dimension is currently the hottest seat in the entire AM industry.

Damn, so many interesting things happened last week… LEGO revealed its first mass-produced 3D printed part, Apple announced the use of metal PBF for manufacturing the new iPhone Air and Apple Watch, and Raise3D presented a new 3D printer.

But once again, all the attention was captured by negatives. German injection molding giant Arburg announced its exit from the AM industry after 12 years. And then this unexpected CEO change at Nano Dimension… The weight of the news remains on the bitter side.

Many wise people have already commented on Arburg, so I won’t repeat what’s been said… Instead, I’ll focus on the fate of Nano Dimension, over which the sky remains cloudy.

Although let’s be honest – hardly anyone cares about Nano itself, but rather about its most valuable asset – Markforged. Because one’s troubles mean the other’s troubles. And from a broader perspective, the future of Markforged looks filled with challenges.

And the main challenge is called FibreSeeker.

You could say that, similar to what happened with Stratasys, Markforged has found its own Bambu Lab. A product that renders its solutions completely unprofitable.

But maybe let’s start from the beginning…

Last Tuesday Nano Dimension announced major leadership changes and the launch of a strategic review. Ofir Baharav was removed from the position of president, and the new CEO became Dave Stehlin, until now a board member.

Stehlin is a US Marine Corps veteran with over forty years of experience managing technology companies.

In parallel with the leadership change, the company hired Guggenheim Securities and Houlihan Lokey as financial advisors to conduct a formal review of strategic alternatives. The goal of this process is to “maximize shareholder value,” which may involve restructuring or divesting key assets.

Yes, you read that right: “formal review of strategic alternatives.” Historically, such wording always means trouble.

And those go back to last year, when the previous CEO, Yoav Stern, was ousted after a failed attempt to acquire Stratasys, as well as absurd acquisitions of Desktop Metal, Markforged, and a series of smaller companies and startups.

On top of that came an internal boardroom power struggle with the main shareholder – Murchinson – which Stern ultimately lost.

On December 26, 2024, Yoav Stern said goodbye to his position, and interim CEO Julien Lederman stepped in. His tenure was relatively short, only 103 days. But that was essentially his role – to lead the company until a new leader was found.

That turned out to be Ofir Baharav, who began by reviewing all assets acquired by Stern and deciding which ones were worth keeping and which had to be sold or shut down.

This is how he described his strategy in a May letter to shareholders:

Transform Nano Dimension into a leader in digital manufacturing of industrial parts, combining advanced software, machine learning, materials engineering, and hardware.

Focus on cooperation with leading industrial companies to produce advanced, complex parts at scale, rather than just prototyping.

Execution discipline and a path to profitability while maintaining a strong capital base.

Rationalize the product portfolio, keeping only those offerings that ensure category leadership and strong returns.

Optimize the operating model by reducing unnecessary G&A costs, breaking down silos, and flattening the organizational structure.

It sounded really reasonable, and moreover, the market – companies and partners within the Nano Dimension conglomerate – was sending very positive signals. Unofficially, people said that Baharav and his team brought an entirely new quality after years of organizational chaos caused by Stern.

Unfortunately, it now turns out that Baharav also failed to stabilize the situation.

During his brief 154-day tenure, Desktop Metal – bought for $179.3 million and once valued at $3 billion – quickly went bankrupt, with its key assets ultimately sold for just $7 million. That included ExOne and EnvisionTEC.

Now the new, fourth CEO – Dave Stehlin – together with board chairman Robert Pons, declare that they will implement changes to rebuild investor confidence, focus on fiscal responsibility, and drive targeted growth.

Nano Dimension promises to continue its work in digital manufacturing solutions for key industries such as defense, aerospace, automotive, electronics, and medical devices.

How do they plan to achieve this? Well, of the entire conglomerate, four key assets remain:

the original proprietary 3D electronics nanoprinting technology (DragonFly series)

Swiss company Essemtec, a manufacturer of advanced assembly and electronics printing systems

British company Global Inkjet Systems (GIS), specializing in advanced control systems and software for industrial inkjet printers

Markforged

The first three form one logical whole, though this technology is quite niche and highly specialized. This very characteristic led Yoav Stern, lacking a better scaling idea, to first attempt buying Stratasys, and when that failed, to go on a wild acquisition spree, which claimed Desktop Metal and Markforged as victims.

Thus, the only truly promising asset is the last one. The key rival to Stratasys in the industrial FDM/FFF systems market.

The problem is, the market is steadily turning away from industrial FDM systems, shifting toward cheap yet highly capable desktop 3D printers like Bambu Lab.

Bambu Lab’s H2D and the recently released H2S have caused such significant disruption to Stratasys’ 3D printer sales that the company sued the Chinese manufacturer last year for patent infringement (partly its own patents, partly MakerBot’s).

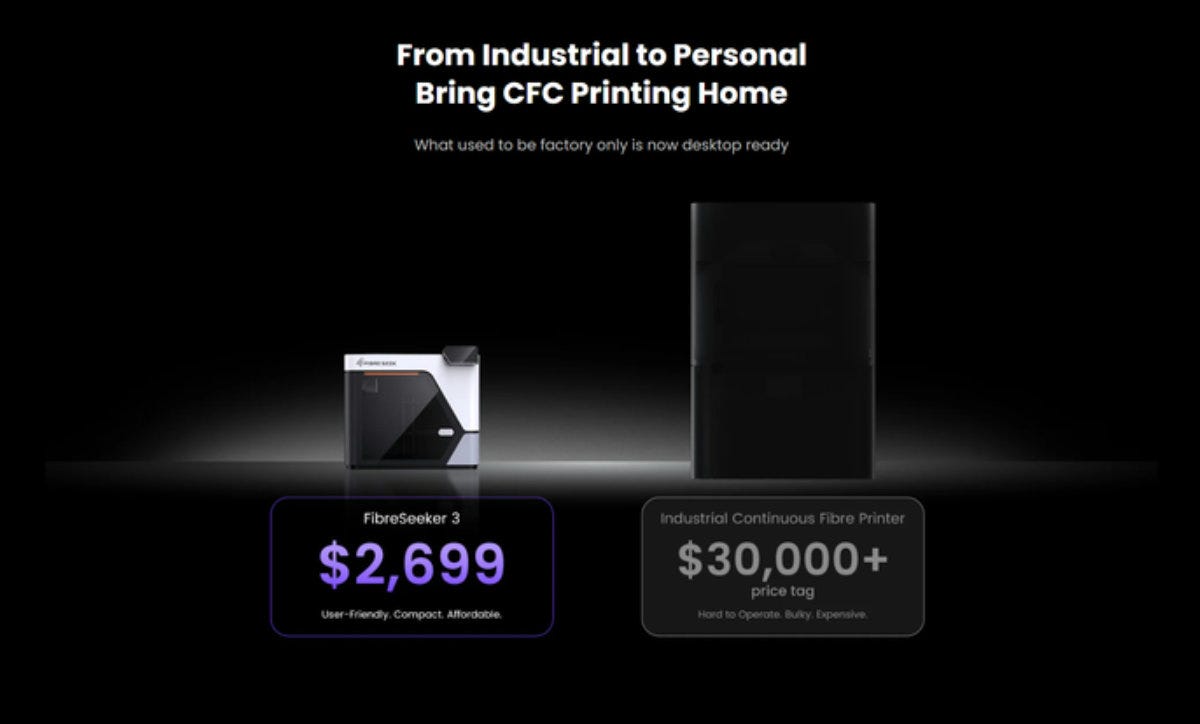

Meanwhile, a completely new competitor has emerged for Markforged in the form of the FibreSeeker 3, advertised as “the First Consumer Continuous Fibre 3D Printer.” Absurd as the phrase “consumer” and “continuous fibre 3D printer” sounds together, the fact is that it has the potential to seriously weaken the already struggling Markforged.

FibreSeeker is a brand developed by Chinese company Anisoprint. It’s soon set to debut on Kickstarter at a price of $2,699. That’s significantly cheaper than “other systems of this type on the market.”

When that happens, and if FibreSeeker 3 proves fully functional, Markforged’s key offering – the continuous fibre 3D printer – will become secondary, and the company’s printers overall will be reduced to mere alternatives to Stratasys’ systems.

Which, in turn, is already losing ground to Bambu Lab, as well as Creality and the rest of the Chinese 3D printer manufacturers.

So the company’s future is uncertain, which naturally translates into uncertainty for Nano Dimension.

I can’t say for sure whether the above topic influenced the latest CEO change, but I’m certain that Mr. Dave Stehlin faces a truly massive challenge…

For now, I just hope his tenure lasts longer than 200 days (a milestone his last two predecessors couldn’t reach).

#7. Zellerfeld introduced a new footwear 3D printing system

Zellerfeld has announced the launch of advanced GEN3 3D printing system. The new technology increases production capacity from thousands to millions of pairs, making printed shoes for the masses a reality. GEN3 prints three times faster than its predecessor, uses multiple colors, and operates fully autonomously. The company has also opened its platform to all designers worldwide, inviting a wave of new on-demand creations.

READ MORE: www.voxelmatters.com

#6. Phase3D has launched Fringe Inspection M2 Series 5 Kit

Phase3D has launched its Fringe Inspection M2 Series 5 Kit, bringing real-time, in-situ quality assurance to the widely used GE Additive M2 Series 5 metal 3D printers. The kit provides operators with objective, layer-by-layer measurement data, enabling them to detect process deviations before they become costly defects. Designed for seamless and reversible integration, it can be installed in under 24 hours.

READ MORE: www.voxelmatters.com

#5. Raise3D has launched the E3 IDEX 3D printer

Raise3D has launched the E3, a new and more affordable version of its IDEX 3D printer. Starting at $2,499, it is significantly cheaper than its predecessor, the E2. The E3 introduces a Flexible Filament Auxiliary Feeder for improved TPU printing and a Pro Ironing feature for superior surface quality. It supports various materials, including composites, with print speeds reaching 200 mm/s.

READ MORE: www.all3dp.com

#4. Apple used metal 3D prinitng for the new iPhone Air and Apple Watch

Apple has officially unveiled its new iPhone Air and Apple Watch Series 11, featuring 3D-printed titanium components for the first time. Using selective laser melting, Apple produces parts that are thinner and stronger than those made conventionally. This process uses 33% less material for elements like the USB-C port.

READ MORE: www.3druck.com

#3. LEGO Group has unveiled its first mass-produced 3D printed piece

LEGO Group has unveiled its first mass-produced 3D printed piece in the new LEGO Icons Holiday Express Train set. The functional train component, manufactured on an EOS FDR system, features internal functionality only possible with additive manufacturing. This move represents a significant step for LEGO, which had previously only created prototype 3D printed pieces. The 956-piece holiday set, priced at $129.99, demonstrates the company's commitment to integrating AM into mass production while meeting its stringent quality and safety standards.

READ MORE: www.voxelmatters.com

#2. Nano Dimension changed CEO (again)

Nano Dimension has appointed a new CEO and launched a strategic review. Dave Stehlin, a board member and veteran executive, replaces ousted CEO Ofir Baharav. The company has retained financial advisors to explore options for maximizing shareholder value, which may include restructuring or asset divestment.

READ MORE: www.3dprint.com

#1. Arburg left the AM industry

German machinery manufacturer Arburg is discontinuing its additive manufacturing activities, closing its ARBURGadditive unit by the end of 2025. The company will refocus entirely on its core injection molding business. Arburg cited a failure to meet economic targets and a slower-than-expected development of the industrial 3D printing market as key reasons. Support and spare parts for existing Freeformer systems will remain available long-term. Approximately 40 employees from the division will be reassigned within the company.

READ MORE: www.3druck.com