Revival of European AM industry will start in overlooked countries

3DP War Journal #70

3D printing was born in the Western world – in the USA, France, Germany, the Netherlands… But today, the leading position in this field belongs to Asian companies, which set the tone and direction of its development.

Western manufacturers are losing their relevance. Service providers are starting to feel pressure from Chinese companies. End users are guided purely by economics and return on investment – not by who made the machines they buy, or where they were made.

Industry analysts and commentators are asking themselves where the mistakes were made – and how to fix them. How to go back to the way things were?

But that’s no longer possible.

The world we knew in the 2000s and 2010s is gone. What we have now is new. Different.

But that doesn’t mean that 3D printing will disappear from Europe or from the Western world altogether. Quite the opposite.

The 3D printing industry will be reborn – but in completely different places, in places no one is looking at right now, places no one takes seriously.

Because honestly… Who among you wouldn’t smile dismissively if I said that today, the best places for the development of the AM industry are Poland, the Czech Republic, Romania, Bulgaria, or Serbia?

Has anyone even been there? Has anyone paid attention?

Well, I have…

And I’ll tell you this – you might not see it yet, but just beneath the surface, a fire is already burning.

Next Layer Conference in Romania

Last Friday, October 31, 2025, I had the pleasure of attending Next Layer – the first (or at least one of the first) AM conferences ever organized in Romania. The event was organized by 3D InBox – a leading reseller of Bambu Lab and other 3D printer brands in the country.

The conference took place in the conference halls of the Novotel Hotel, right in the heart of Bucharest, the capital city. Nearly 200 people attended – professionals, engineers, business owners, as well as representatives from universities, including student clubs.

An important point – this was not a free event!

Every participant bought a ticket, which – given the number of attendees – is a huge success for the organizers. It also shows how hungry for knowledge Romanians are!

And judging by the audience’s reactions, I know no one left disappointed.

Speakers included:

Davide Sher – CEO, co-founder, and chief editor of Voxel Matters, and one of the most renowned journalists in the AM industry.

Manuel Jiménez García – co-founder and CEO at Nagami, a robotics manufacturing company specializing in large-scale 3D printing applications using recycled materials.

Neha Sharma – co-founder and medical director of POC APP AG, a Swiss MedTech company specializing in MDR-compliant production for point-of-care medical applications.

Călin Gruia – Founder of Plastic3D and Romania’s most well-known 3D printing content creator.

Roxana Hurducaș – Brand Strategy Advisor at Arrow and co-founder of Drivion, a strategic marketing agency.

Dr. Bogdan Acatrinei – dentist with over 20 years of experience, specializing in implantology and prosthetics; one of the pioneers of digitally guided implantology in Romania.

Ciprian Marinescu – Head of Creativity and Innovation at Creative Lab and corporate trainer for Renault Technologies Roumanie.

Dr Adrian Rotaru - Scientific Researcher at Extreme Light Infrastructure - Nuclear Physics Center.

And then there was me...

The whole event was hosted by the fantastic Marian Andrei – journalist and producer at PRO TV, and a member of the iLikeIT team.

Now read this…

In 13 years of my career, I’ve attended nearly a hundred AM conferences in Poland and across Europe.

I’ve organized or co-organized almost twenty of them myself.

And this Romanian conference was the best-organized AM event I’ve ever attended.

The professionalism, the scale, the visuals – this wasn’t a conference, it was a freaking AM Show!

Davide Sher can confirm it – we talked about it. It was a completely different level and standard.

None of us expected that. Not in Romania.

Events like this are supposed to happen in the “big and well-known cities,” in the “cradles of AM.” Not in post-communist republics that most people can barely find on a map...

Well, take a look now…

No, Romania isn’t a big 3D printing market today. It’s not even a big industrial production market. But give them a little time – let them build up momentum. You’ll see in 5–8 years...

All photos courtesy of Next Layer / 3D InBox. All right reserved.

Central Europe

But the same thing is happening in other places “forgotten by the god of 3D printing.”

In September, I visited Serbia, where in Belgrade, at the headquarters of 3D Republika, I attended a smaller mini-conference. It was meant to be a modest local event showcasing the new 3D printer – Bambu Lab H2D Pro.

My participation was supposed to be purely symbolic – just to support the local distributor as a CSM representative.

But dozens of people showed up! After my talk, there was a long discussion with participants, followed by many more conversations in the showroom and during later presentations. Fantastic atmosphere, great people.

Then came the Bambu Lab MeetUp in Warsaw, organized by Edutech Expert. Again, nearly 100 people. Again, lots of discussions and conversations.

Finally, the event in Zagreb, Croatia, organized by 3DPrintaj in mid-October. Unfortunately, I couldn’t attend due to a scheduling conflict (we had the P2S launch at the same time), but judging by the photos and reports, the same pattern repeated once more.

Alright, I know what you’re thinking – “Dude, what’s the big deal? That’s normal stuff. That happens everywhere. Really...? Seriously?”

Yes! Seriously!

Because this is about emotion – about interest – about the enthusiasm of the participants.

It’s exactly the same as 10–12 years ago. The same spark, the same hope.

Attending these events – in Bucharest, Belgrade, or Warsaw – I feel like I’m going back to the roots.

The audiences are mixed – some are old 3D printing veterans who started before 2015. But others are newcomers, who got into it only after the pandemic. Who are just now discovering this world.

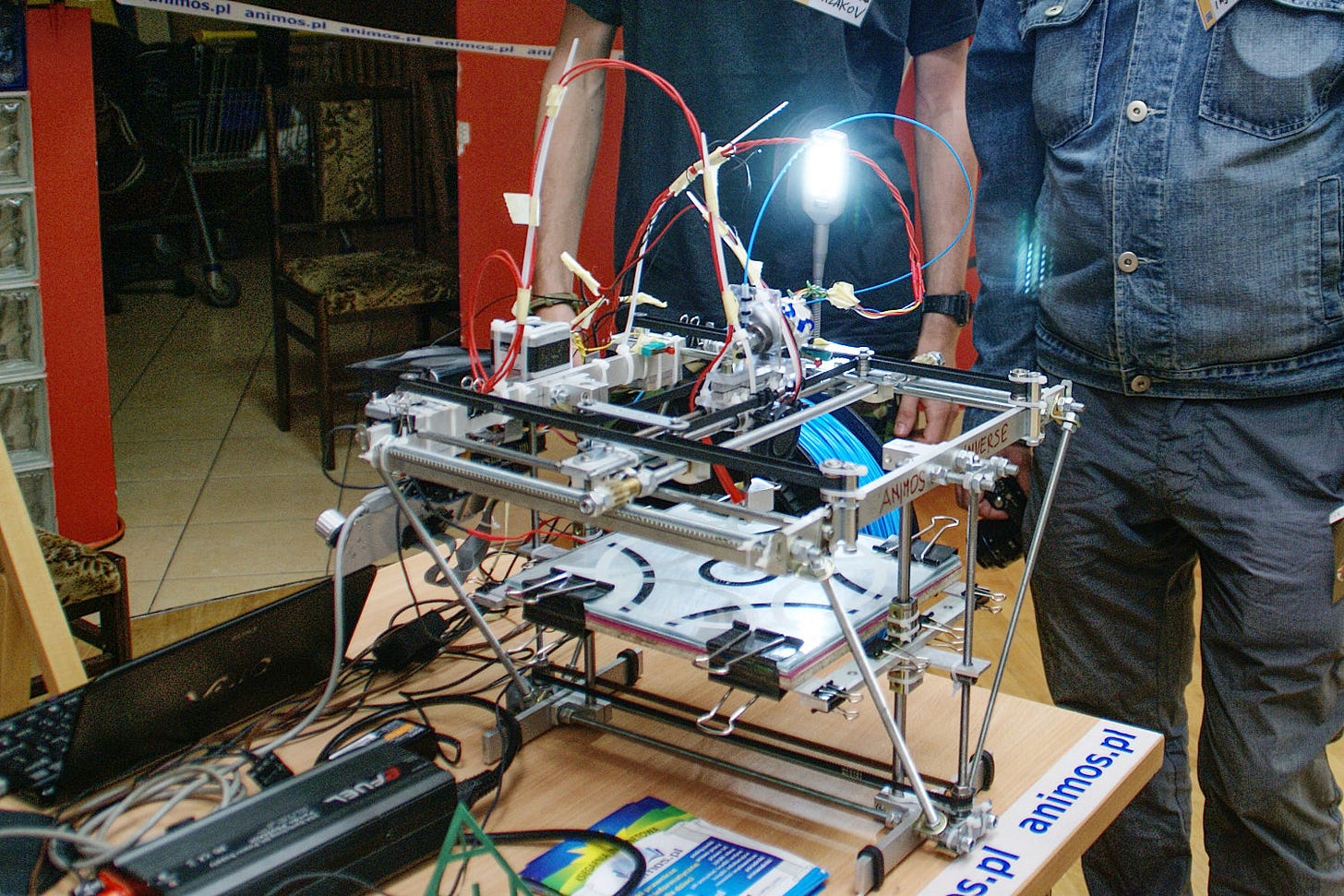

Fortunately for them, today’s 3D printers are different. They’re no longer those wooden, cable-tangled DIY machines where success meant simply finishing a print – without it failing halfway through.

The new generation of 3D printers allows users to focus purely on what the technology can give us, not on how to fix, upgrade, or rebuild the printer itself.

This enthusiasm is very strong in Central and Eastern Europe – in places where no one ever looked, and where no one ever expected anything.

No one looked at us – at Poland – for years either…

If it weren’t for Zortrax, no one would have even known we existed. And now we’re one of the five largest markets in Europe. And we’re still growing...

And as for the rest – you may not see it yet, but just beneath the surface, the fire is already burning!

#7. Josef Průša honoured by Czech Republic President

President Petr Pavel awarded state honours at Prague Castle. Among the 48 recipients was Josef Průša, one of the youngest Czech billionaires (in Czech currency). He was recognized for his economic merits in the 3D printing revolution. The ceremony also honoured other prominent figures from science, sports, and culture.

READ MORE: www.forbes.cz

#6. BYD’s 3D-printed supercar breaks record

BYD’s Yangwang brand has revealed the 3D-printed chassis behind its U9 supercar’s record-breaking Nürburgring lap. The vehicle is the first production EV to complete the circuit in under seven minutes. Its chassis uses a laser-melted, high-strength aluminum alloy, making it exceptionally strong and light. A parametric modeling technique created a honeycomb-like internal structure, boosting torsional stiffness by over 200%.

READ MORE: www.voxelmatters.com

#5. New ASTM standard for faster material testing in AM

ASTM has published a new standard, E3499-25, for Profilometry-based Indentation Plastometry (PIP). Developed by Plastometrex with partners like Airbus and Renishaw, this method allows for the rapid and material-efficient determination of mechanical properties. It is particularly useful for testing small or thin-walled additively manufactured samples where traditional tensile tests are impractical.

PIP reconstructs stress-strain curves by analyzing the indentation profile and using inverse finite element analysis. It provides key values like yield strength and tensile strength. This standard is expected to accelerate parameter studies and quality checks in AM workflows, offering a reliable alternative to conventional testing methods.

READ MORE: www.3druck.com

#4. Apple expands 3D printing for new devices

Apple is increasing its use of additive manufacturing, creating a new engineering role in Shenzhen to scale metal 3D printing processes. This expansion supports the production of the new iPhone Air and Apple Watch Series 11. Both devices feature titanium components, such as the iPhone’s USB-C port, made with this technology.

Apple states that 3D printing creates stronger parts while using less material, contributing to the company’s sustainability goals by reducing waste and incorporating more recycled content. This move solidifies additive manufacturing’s role in Apple’s future supply chain.

READ MORE: www.voxelmatters.com

#3. SHINING 3D launched All-in-One inspection scanner

SHINING 3D Metrology has launched the FreeScan Omni, a portable, wireless 3D scanner. The device is a complete inspection solution, integrating high-speed scanning and onboard data processing. Its key feature is the PTB-certified inspection module, which allows for instant automated analysis and reporting directly on the device.

READ MORE: www.voxelmatters.com

#2. Stratasys launched hardware-agnostic iAM marketplace

Stratasys has launched the iAM Marketplace, an independent and hardware-agnostic platform. It aims to streamline purchasing and make AM supply chains more agile. The platform unites the expertise of iSQUARED and Forward AM, also utilizing assets from Nexa3D. It offers a wide selection of certified polymer materials, services, and products.

READ MORE: www.tctmagazine.com

#1. Prusa introduced larger Core One L 3D printer

Prusa Research has launched the Core One L, a larger version of its Core One printer. It features a significantly increased build volume of 300 x 300 x 330 mm, doubling the original’s capacity while only increasing the printer’s physical footprint by 10%. Key improvements include a new convection heating system for faster chamber warm-up and several quality-of-life upgrades, such as an automated vent and an enhanced webcam. Priced at $1,699, the printer is factory-calibrated for easy setup. A security-focused version without networking is also available.

READ MORE: www.all3dp.com

I visited a trade fair in Brno, Czechia last November and was excited to see a vibrant set of 3D printing displays. I head to Romania later this month and will keep my eyes open!