Sinterit gets another drip feed

3DP War Journal #64

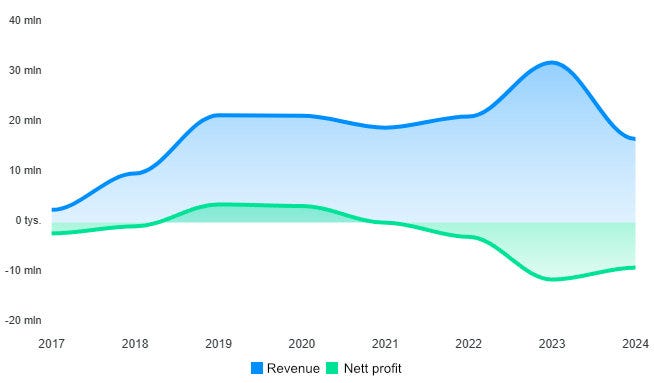

Sinterit, a pioneer of desktop SLS printing, is facing challenges. The company has once again been funded by its main shareholder, FIT AG. This “financial drip-feed” strategy raises doubts about its condition – especially in the face of Formlabs’ Fuse 1 market dominance.

Poland was once one of Europe’s leading producers of 3D printers. 8–10 years ago, we had an impressive portfolio of companies: Zortrax, Zmorph, Sinterit, 3DGence, Omni3D, Hbot3D, Verashape, Monkeyfab, Sandmade, and many others. Today, only three from that list still operate globally – the rest either no longer exist, have changed their business profile, or are simply fading away…

Practically all Polish manufacturers built 3D printers using FFF technology – with the notable exception of Krakow-based Sinterit, which specialized in SLS. Together with Swiss company Sintratec, it was a pioneer in transforming this expensive, industrial production method into an affordable desktop solution.

In the second half of the 2010s, both companies created an entirely new market segment, becoming its natural leaders. Unfortunately, this changed in 2021, when Formlabs launched the long-awaited Fuse 1. The American manufacturer quickly took the lead, practically taking ownership of the desktop SLS market.

Sintratec couldn’t keep up and declared bankruptcy in early 2024. Sinterit is still fighting. But judging by recent press reports, it’s a truly exhausting fight…

For those who don’t remember how it all looked – a quick recap…

Sinterit was founded in 2014 in Krakow by Michał Grzymała-Moszczyński, Konrad Głowacki, and Paweł Szczurek. At that time, the SLS 3D printer market was dominated by expensive industrial machines costing hundreds of thousands of euros, which severely limited access to the technology.

Sinterit’s first 3D printer – the compact Lisa – became a breakthrough in the desktop segment. When it hit the market in 2015, it cost just a few thousand euros, creating a new category of machines.

In the following years, Sinterit grew dynamically, building a network of distributors and expanding its portfolio. The company stood out from the competition with its “open parameters” feature, allowing the use of third-party materials and research experiments.

In 2016, the company secured its first international resellers, enabling expansion beyond Poland and solidifying its position as a leader in affordable SLS printers.

2017 brought a key financial milestone – Sinterit raised €1.1 million in a share issue financed by German company FIT AG, a leader in prototyping and additive manufacturing services.

In 2020 came another important round – a $2.58 million seed round, led by the Polish fund EEC Ventures.

These funds allowed for further scaling of production and R&D, including the development of new models like Lisa Pro.

By that point, the company had raised a total of around $3.76 million, including earlier support from PFR Ventures and the Małopolska Centre for Entrepreneurship.

Unfortunately, 2021–2023 brought serious market challenges, as in January 2021 Formlabs introduced the Fuse 1, which quickly captured nearly half of the entire SLS 3D printer market, putting Sinterit in a very tough competitive position.

Nevertheless, the Polish company continued to innovate, introducing improvements to the Lisa X line and focusing on low-cost materials like PA11 powder.

In early 2024, the original competitor – Sintratec – couldn’t keep up and closed down.

Shortly after, in mid-2024, Sinterit secured additional funding from its main shareholder – FIT AG. In July of the same year, it raised $1.85 million in a share issue guaranteed by existing investors, including FIT and EEC Magenta.

These funds were allocated to increased marketing spending, productivity improvements, and the development of a new generation of printers.

At the same time, there was a management shake-up – Albert Klein, an experienced German manager, became the new CEO, initiating stronger integration with FIT AG and transferring operational control to the German team.

Konrad Głowacki – the original CEO – was gradually marginalized, eventually leading to his departure from Sinterit.

In March 2025, Sinterit unveiled its newest printer, Suzy – one of the cheapest SLS machines produced in Europe, targeted at small-batch production and prototyping.

But perhaps not everything went as planned…

Last week, Sinterit announced that FIT AG had ordered “more than thirty Lisa X and Suzy 3D printers.” FIT also provided a second round of funding within the year to support further development, including a new, competitively priced PA11.5 powder.

Unfortunately, this shows that Sinterit’s situation is rather bleak, and the company is struggling to sustain itself independently in the market.

The fact that FIT AG has to intervene annually, buying dozens of printers and injecting new capital, is a telling sign of the company’s declining business health.

This looks more like artificial life support than organic growth – and casts doubt on the real value and competitiveness of Sinterit’s offering.

Formlabs, which is becoming increasingly aggressive in the SLS market, now competes only with large-system manufacturers (such as EOS or 3D Systems). Sinterit can only try to catch up, but it won’t achieve that by announcing the sale of 30 printers to its own owner…

For me personally, this is a rather sad turn of events for what was once an extremely promising Polish startup – in its pioneering years, it inspired great hope as a technological gem and proof that Polish companies could compete with innovation on a global level.

PS: Some of you may have been expecting an article commenting on last week’s resurrection of Desktop Metal? Well, sorry, but after reviewing the official press release I concluded that, for now, there’s nothing to write about. Maybe at some point it will turn out to be significant? Here-and-now – Meh...

#7. Caracol expands US footprint with new Austin headquarters and production hub

Caracol has inaugurated its new US headquarters and production center in Austin, Texas. The 10,000-square-foot facility triples the company's capacity for systems production and application development. The facility is equipped to produce up to 100 Heron AM and Vipra AM robotic platforms annually.

READ MORE: www.voxelmatters.com

#6. Nano Dimension reported 72% year-over-year revenue increase

Nano Dimension has reported a 72% year-over-year revenue increase to $25.8 million in Q2 2025, largely driven by its recent acquisition of Markforged. Despite this growth, the company posted significant losses and a reduced gross margin. The quarter was marked by major changes, including the acquisition and subsequent Chapter 11 filing of Desktop Metal, which resulted in a substantial impairment charge.

READ MORE: www.voxelmatters.com

#5. Tencent unveiled Hunyuan 3D 3.0 AI platform for automated 3D content generation

At the Global Digital Ecosystem Summit in Shenzhen, Tencent introduced Hunyuan 3D 3.0, the latest version of its AI-powered 3D content generation platform. Designed for gaming, media production, and design, the toolset aims to significantly reduce modeling and texturing efforts for developers. The company also launched Hunyuan 3D AI and Hunyuan 3D Studio, integrating them into enterprise SaaS workflows to enhance efficiency. Tencent reported its open 3D models have been downloaded over 2.6 million times on Hugging Face, ranking among the world's most widely used.

READ MORE: www.3druck.com

#4. Sinterit secured major printer order and financing from FIT AG

Sinterit has received a significant order for over thirty Lisa X and Suzy 3D printers from its key shareholder, FIT Additive Manufacturing Group. The German-based company has also provided Sinterit with a working capital loan to support its next growth phase.

READ MORE: www.voxelmatters.com

#3. Desktop Metal relaunched under new ownership after asset sale to arc impact

Desktop Metal is being relaunched under new ownership after investment group Arc Impact Acquisition Corporation acquired select assets from its Chapter 11 bankruptcy proceedings. The purchased intellectual property includes binder jet technologies, Adaptive3D's DuraChain elastomers, and FreeFoam resins. The new leadership plans to deploy these assets through a distributed R&D-as-a-Service network with universities, focusing on advanced manufacturing for economic competitiveness and national security.

READ MORE: www.tctmagazine.com

#2. Formlabs launched Form Now 3D print-on-demand service

Formlabs has announced Form Now, its new web-based 3D print-on-demand service. Initially available in the U.S., the service allows customers to order printed parts directly from Formlabs, with delivery promised in less than a week. The service is currently in a beta phase, requiring interested users to join a waitlist.

READ MORE: www.fabbaloo.com

#1. Divergent Technologies secured $290 million in series E funding

Divergent Technologies has raised $290 million in a Series E round led by Rochefort Asset Management. The financing includes $250 million in equity and $40 million in debt, valuing the company at $2.3 billion. The funds will be used to scale its Divergent Adaptive Production System (DAPS) manufacturing platform and develop new capabilities for aerospace, defense, and automotive customers. The company has significantly expanded its customer base, now manufacturing over 600 part numbers for clients including Lockheed Martin, Raytheon, and Aston Martin.

READ MORE: www.tctmagazine.com