Split3r – a super smart solution for large-scale 3D printing

RECODE.AM #15

Desktop 3D printing with FFF technology has undergone a true revolution over the past three years. 3D printers are now faster, cheaper, and more reliable than ever before.

However, despite major progress in quality and accessibility of hardware, there is still one barrier that cannot be overcome – the size of the build chamber.

The standard today is printers with a build volume ranging between 25–33 cm in the XYZ axis. This works great for most projects: prototypes, accessories, mechanical parts, or decorations.

But when it comes to printing something truly large – a car body panel, a piece of furniture, a cosplay prop, or an architectural model – a major challenge arises.

Of course, large-format 3D printers do exist on the market, but these are niche, expensive, and impractical solutions. Such machines can take up half a room, cost tens of thousands of euros, and print slowly.

That’s why many users ask themselves: if we can buy ten small printers and run them in parallel, why can’t we simply split a large model into smaller, well-fitted pieces?

Current solutions

Up until now, tackling large projects required a lot of patience and compromises. The simplest method was manually cutting STL models in 3D mesh editing software such as Meshmixer or Blender.

Unfortunately, this was a time-consuming task, requiring significant skill and a solid understanding of 3D geometry. Anyone who has tried preparing a complex project this way knows how many hours it can take to perfectly align cutting planes and design joints that will later allow the parts to fit together.

Dedicated software for such tasks has also been created. One of the most popular is Luban, which allows automatic splitting of objects into parts and then adds simple alignment pins.

Unfortunately, the splitting process is often random, lacking options for smart placement of cuts, making assembly harder. On top of that, the generated joints don’t always ensure precision and stability.

As a result, most makers continued using the simplest method: manually cutting STL files and painstakingly preparing the joining surfaces.

This meant hours of extra work, with final results often far from perfect.

The birth of Split3r

That’s why Split3r was created – software designed specifically with large-scale prints in mind, but on standard FFF printers.

The author of the software is Philippe Boichut, founder of Qualup SAS, a French company specializing in the design and production of industrial FFF 3D printers for working with demanding high-performance materials.

The company has been active in additive manufacturing since 2011 and first became known for its SpiderBot model – the first delta-type 3D printer with a heated chamber (thanks to delta kinematics, Qualup SAS avoided infringing Stratasys patents).

01-29-2016: Qualup introduced the first FFF delta 3D printer with a closed and heated build chamber

Later, in the Qu3-HT model introduced in 2022, they implemented innovations such as a filament compensation system and an adaptive build chamber that dramatically reduced heating time (e.g., to 245 °C in just 10 minutes).

The idea for Split3r was born during a late-night printing session: instead of endlessly searching for bigger and more expensive machines, why not try to intelligently split the model so it fits within the build volume – and then easily assemble it afterward?

This was the birth of a project that has now entered a key stage of development. A Kickstarter crowdfunding campaign for Split3r has been launched, giving the community a chance to support the solution and gain access to the beta version.

How Split3r works and what it can do

Split3r is built on a solid foundation – its geometry engine leverages proven technology from Blender, ensuring reliability and precision.

It supports large STL files (up to 250 MB), containing millions of triangles, and processes them surprisingly quickly.

In practice, this means a full-size car bumper can be split into over a hundred parts in just fifteen minutes – and on a standard PC.

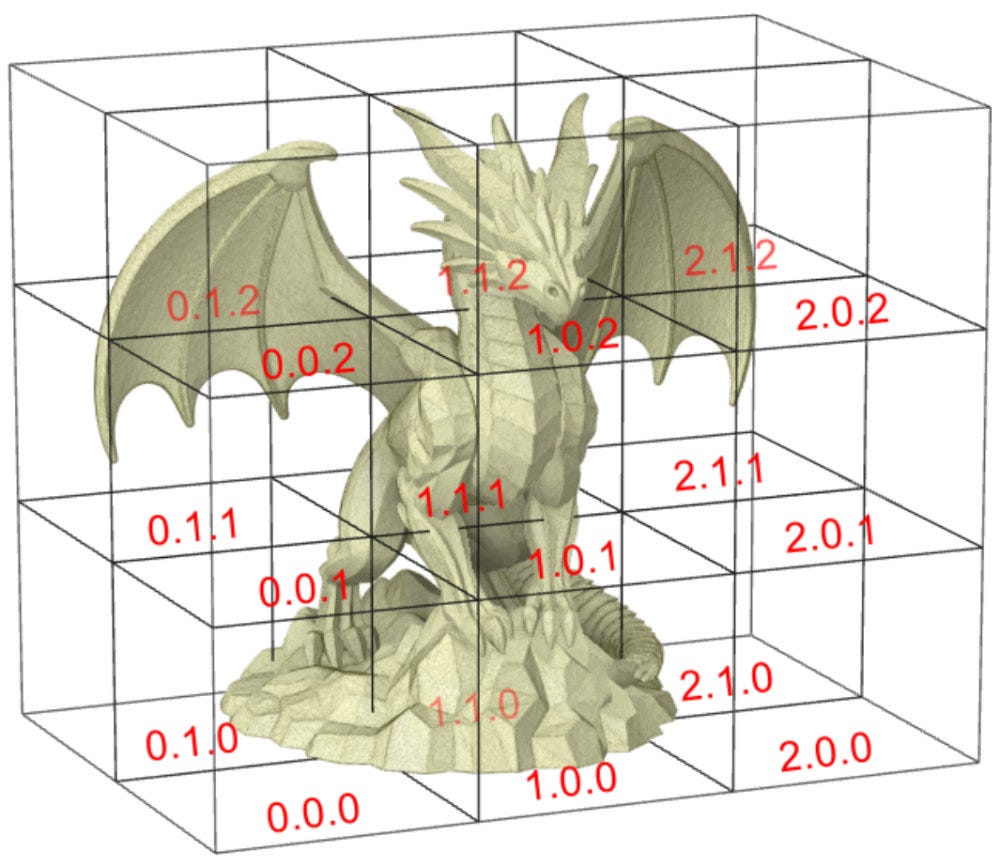

The workflow has been simplified as much as possible. The user imports an STL model, selects cutting parameters, and chooses their printer from over 150 available profiles.

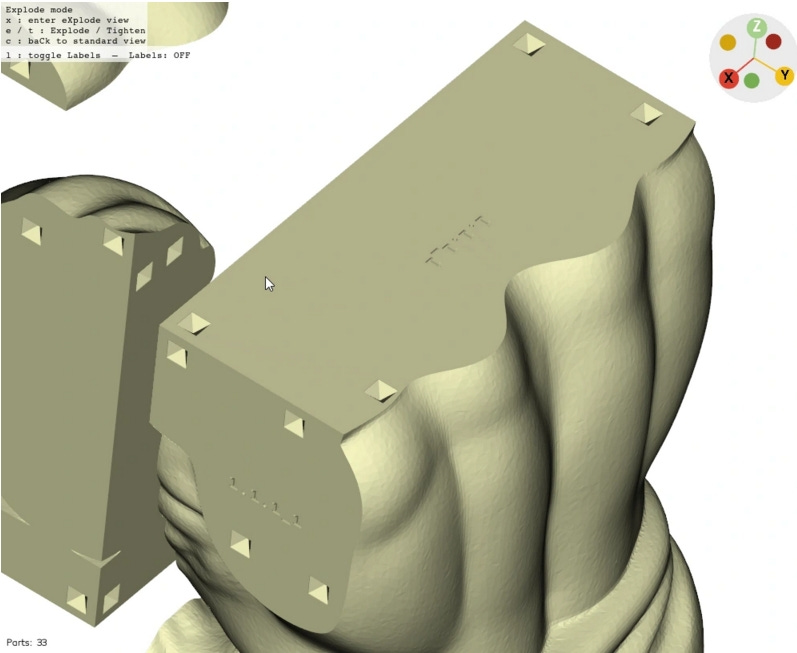

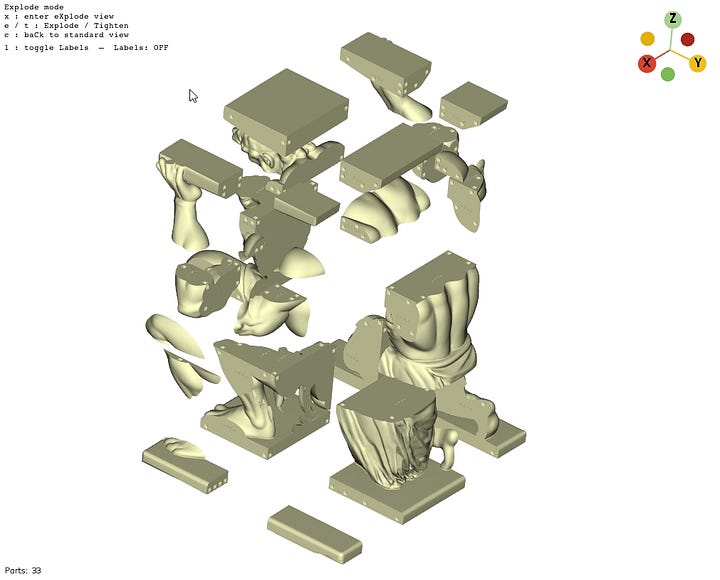

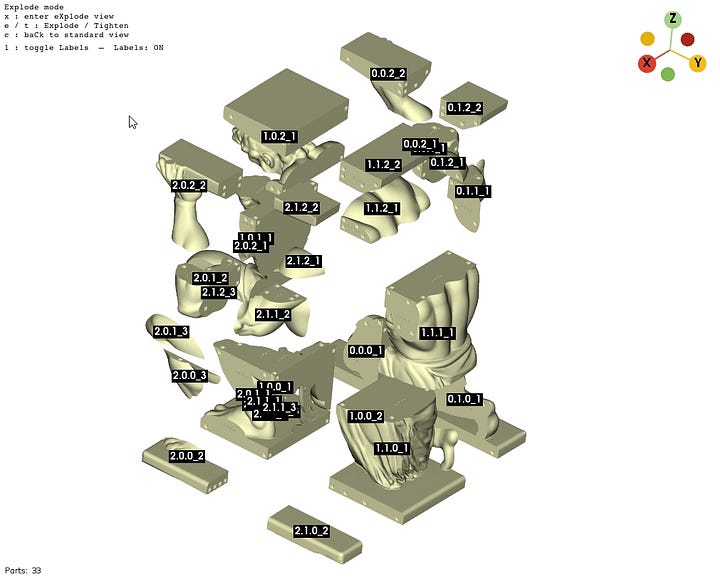

Split3r automatically divides the object into smaller parts, adds fitting joints in the form of hollow pyramids, and generates alignment pins (tenons).

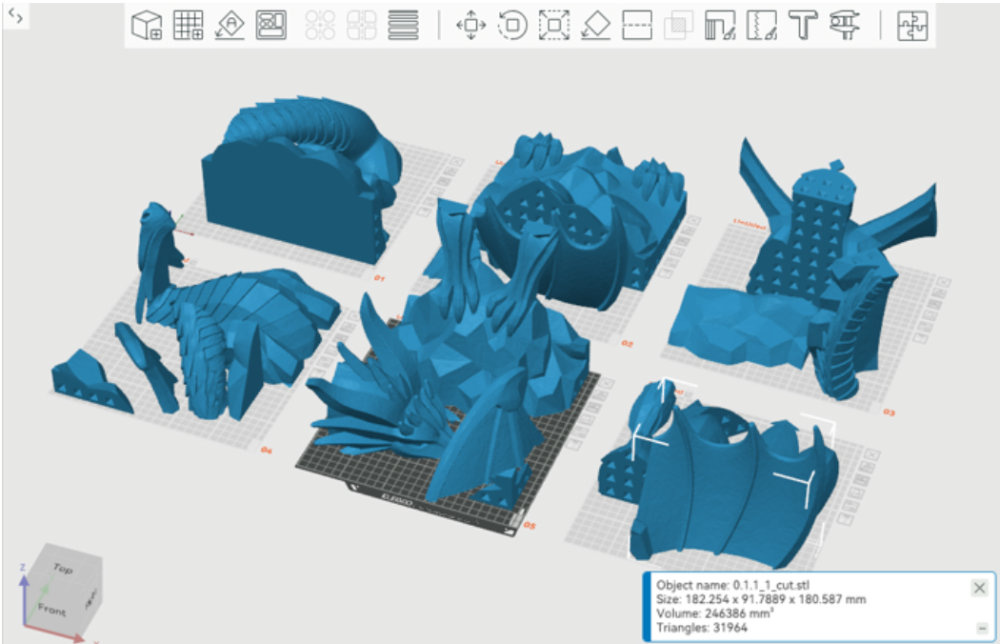

All of this can be previewed in real time in 3D view mode and then exported as ready-to-print STL files for use in a favorite slicer such as Bambu Studio, OrcaSlicer, or PrusaSlicer.

One of Split3r’s greatest strengths is its smart joint design. The software generates cutting surfaces in ways that minimize the need for supports while making final assembly easier.

Alignment pins can be placed as desired – the user decides whether to use many or just a few for axis alignment.

Additionally, all parts receive automatic labels in the form of engraved numbers and logical file naming, greatly simplifying sorting and assembly of large builds.

Another revolutionary feature is Exploded View mode. This allows the entire model to be visualized as a “blown apart” structure, not only making it easy to verify cut accuracy but also serving as an intuitive assembly guide.

In practice, Split3r transforms a farm of FFF printers into a powerful production line.

Instead of printing one huge part for 120 hours, the model can be split into sections and printed in parallel on several machines within a dozen hours.

If a failure occurs, a single part can quickly be reprinted without having to restart the entire project. This saves huge amounts of time, material, and frustration.

Crucially, the program does not require advanced CAD skills. Everything comes down to three steps:

preparing the cuts,

generating files,

and exporting to a slicer.

Built-in repair tools handle minor mesh errors, and advanced options are available for power users, such as adjusting clearance for joints, designing custom tenons, or setting the number of pins per face individually.

The Future of large-scale 3D printing

Split3r is not just software – it represents a new philosophy in 3D printing. Instead of fighting hardware limitations, we use smart software to bypass them and turn them into advantages.

Instead of one giant, expensive printer, we can use multiple smaller, more affordable machines that, together, achieve more than a single device could.

The Kickstarter campaign is intended to help the creator fine-tune the final details: optimizing multithreaded performance, polishing the interface, adding translations, and running stability tests.

The plan is to release the beta version in fall 2025 and a full release by the end of the year. Importantly, Split3r will not require subscriptions – only a one-time license.

This gives makers, artists, educators, and small businesses access to technology that was previously reserved for the most expensive industrial machines. It becomes possible to print life-size figures, vehicle components, large architectural models, or industrial prototypes – all on equipment that many people already have in their homes and workshops.

Perhaps the time has finally come when the question “But what if I want to print something really big?” will no longer be a problem.