04-27-2021: Stratasys introduced the H350, powered by SAF technology, and the large-format F770 FDM 3D printer

SAF technology was presented just a month earlier

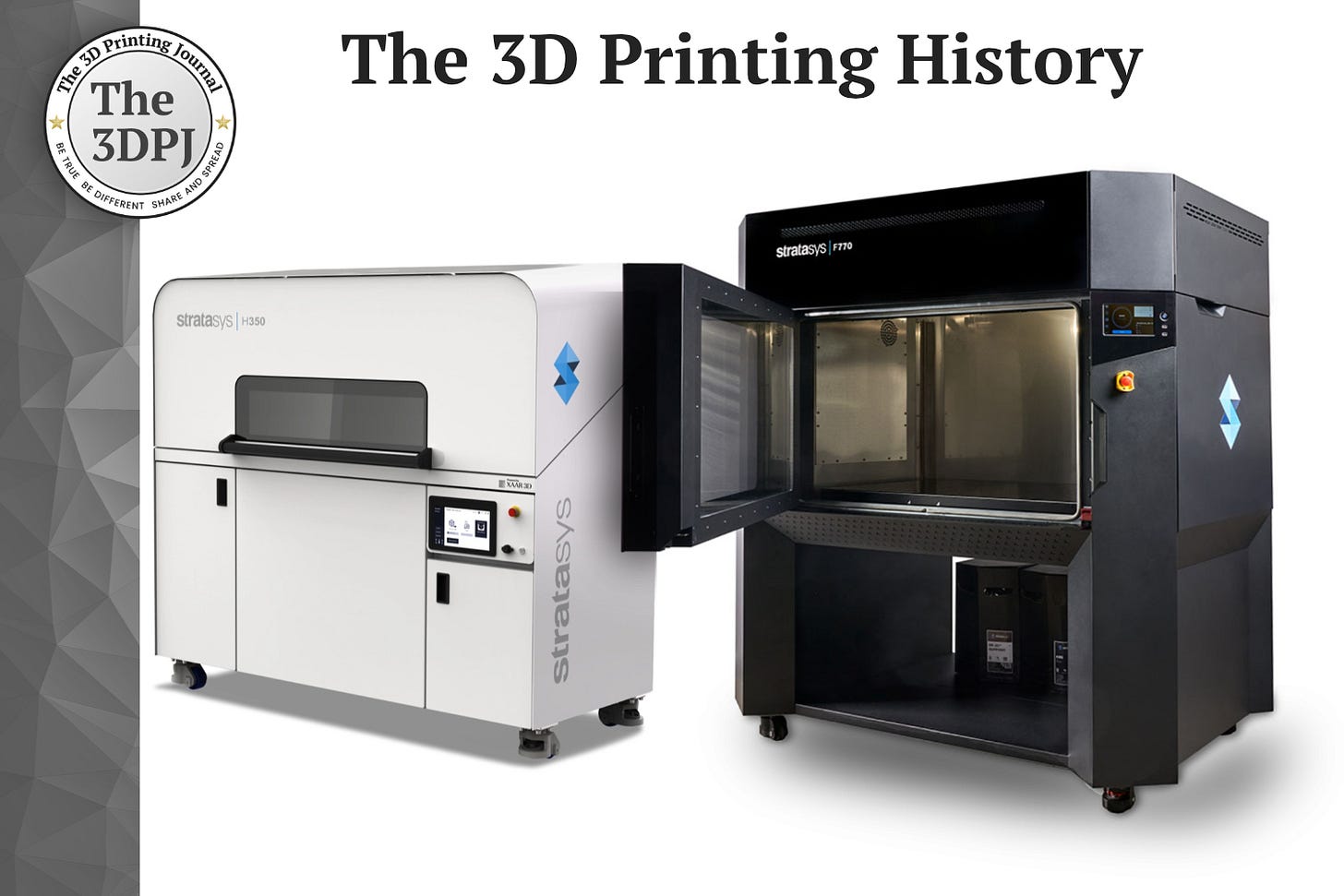

On April 27, 2021, Stratasys unveiled two new 3D printers, with the first significantly expanding its portfolio. The H350 was the company’s first 3D printer utilizing powder-based SAF (Selective Absorption Fusion) technology, which had been introduced a month earlier, on March 27, 2021. The second innovation was the large-format FDM system, the F770, which extended production capabilities in thermoplastic processing.

The Stratasys H350 was developed specifically for the serial production of end-use parts. SAF technology worked by selectively applying an energy-absorbing fluid (HAF) to layers of polymer powder in a single pass. The process used industrial piezoelectric print heads for precise fluid dispensing, followed by an infrared lamp to fuse the selected areas. The Big Wave system ensured even powder distribution and recirculation of excess material, minimizing powder aging and reducing costs.

The H350 supported certified third-party materials, with the first available material being Stratasys High Yield PA11 — a bio-based polymer with a lower environmental impact and superior mechanical properties compared to conventional PA12. Additionally, the printer offered advanced process tracking and data logging features, high packing density for parts, and open integration with manufacturing software platforms such as Materialise Magics and Siemens NX.

At the same time, Stratasys introduced the F770, the largest FDM printer in its portfolio in terms of build chamber size. The system offered a build volume of more than 13 cubic feet (372 liters) and featured the longest fully heated build chamber in the industry, with a 46-inch diagonal. The F770 was designed for printing large prototypes, functional production parts, and extensive industrial tools and fixtures.

Supporting standard thermoplastics like ASA and ABS-M30, along with SR-30 soluble support material, the F770 enabled the creation of complex geometries with minimal post-processing. With integration to GrabCAD Print and support for the MTConnect standard, the printer offered a simple and intuitive CAD-to-print workflow, along with remote device monitoring via mobile applications.

With high precision of less than 0.25 mm on the XY axis and the ability to operate for up to 140 hours of unattended printing, the F770 became an attractive alternative to traditional manufacturing methods, helping to eliminate the high costs and long lead times typical of machining.

Source: www.stratasys.com & www.stratasys.com