Terry Wohlers’ fulfilled fear

The Atomic Layers: S10E10 (00277)

Atomic Layer of the Day:

As I’ve mentioned many times before, while researching materials for my historical series, I occasionally stumble upon real gems—additive manufacturing time capsules.

That was the case with the once-famous, now completely forgotten ING report on the 3D printing market:

That was also the case with the unfulfilled revolution that Desktop Factory was supposed to bring to 3D printing:

Today, I’ve found something else intriguing. A kind of prophecy that ended up coming true in a dramatic way.

12 years ago, Terry Wohlers feared the U.S. would lose its edge in additive manufacturing.

I recently came across an article on 3ders.org with exactly that title. The article quoted a now-defunct blog post from Wohlers Associates, where the legendary analyst and consultant described the state of the AM market back in 2013, warning that America—historically the cradle of 3D printing—might lose its dominant position.

According to 3ders.org, Terry Wohlers wrote the following:

16 companies in Europe, 7 in China, 5 in the U.S., and 2 in Japan now manufacture and sell professional-grade, industrial additive manufacturing (AM) and 3D printing systems.

This is a dramatic change from a decade ago when the mix was 10 in the U.S., 7 in Europe, 7 in Japan, and 3 in China.

In case you didn’t know or don’t remember, the U.S. president at the time was still Barack Obama. A year earlier, he had announced the launch of the new National Additive Manufacturing Innovation Institute. Its goal was to improve the state of American industrial manufacturing and, in particular, to ignite the production of industrial-grade 3D printers.

But Wohlers continued:

What's more, all of the metal powder bed fusion systems are manufactured outside the U.S. Seven manufacturers of these systems are in Europe and two are in China. Together, China, Singapore, many countries in Europe, and even South Africa, have committed hundreds of millions of dollars in AM development and commercialization over the next few years.

The U.S. continues to lead the world with the largest installed base of AM users. When Wohlers Report 2013 becomes available soon, it will report that 38% of all industrial AM installations are in the U.S. Japan is second with 9.7%, followed by Germany with 9.4% and China with 8.7%. With such a large number of systems, one could argue that the U.S. has the most experience, expertise, and know-how in AM.

The NAMII was launched by the White House with the support of several agencies, including the Department of Defense. This initiative seeks to accelerate the position of the U.S. in the development and use of AM technology. It will not be easy, given what organizations in China and other regions of the world have planned.

My recommendation to key leaders in the U.S. is to focus on the big picture with big goals, such as the development of metal-based powder bed fusion systems and other advanced AM system technology. Market forces and competitive pressures will take care of the smaller challenges and incremental technology improvements.

As we know, not long after that blog post was published, things began to change. A new generation of industrial AM system manufacturers emerged in the U.S.—Carbon, Desktop Metal, Nexa3D, and Velo3D, among others.

The problem is that most of them have since declined to such an extent that the whole story has come full circle, and we've essentially returned to square one (the point in time when Wohlers wrote his post).

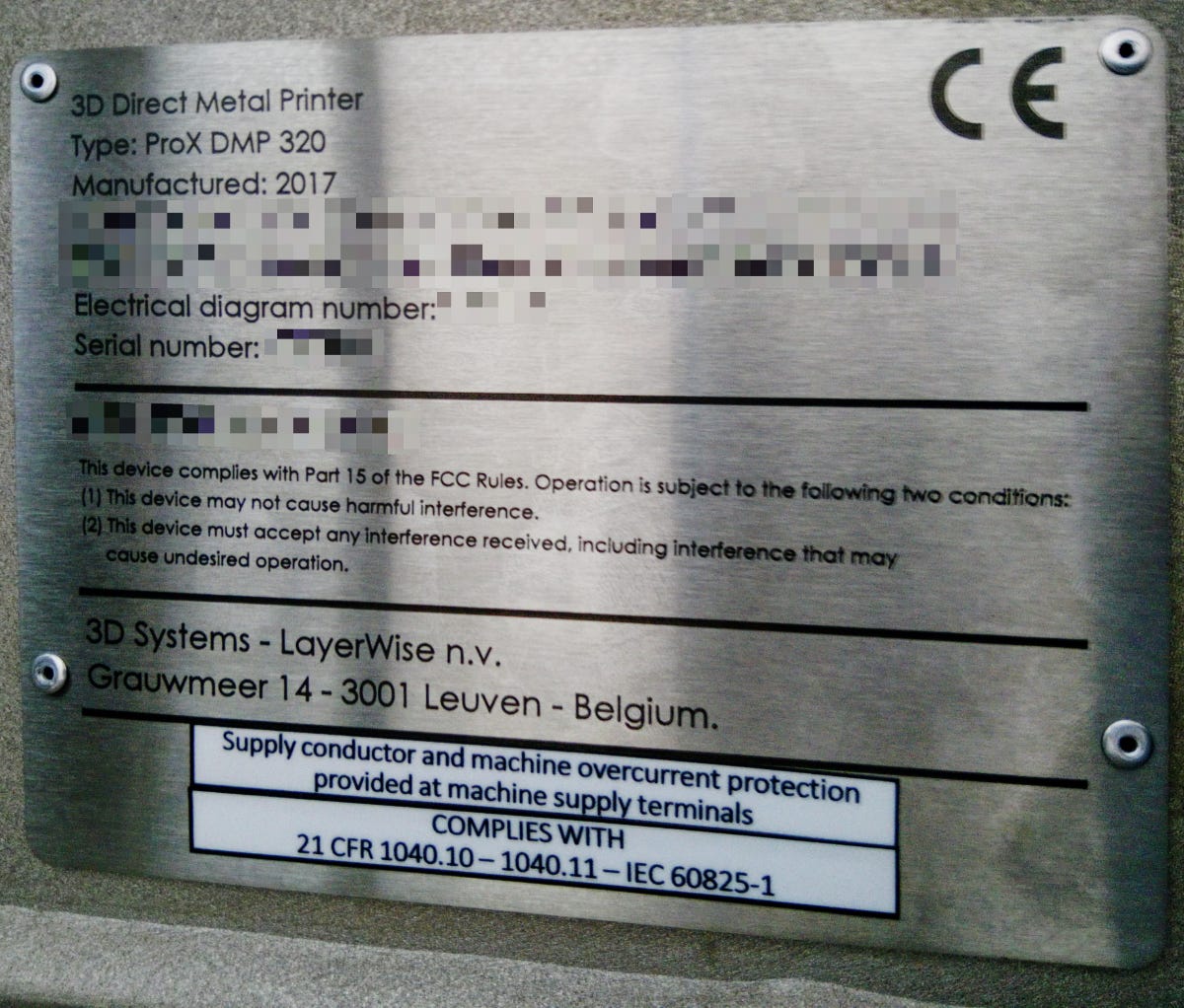

When it comes to metal, PBF systems on American soil are now primarily manufactured by German companies—EOS and SLM Solutions (though the latter is now essentially Japanese). Velo3D is theoretically still producing them (at least I assume so, however lately they mostly talk about providing AM services). Meanwhile, 3D Systems has always manufactured its metal printers in Belgium.

On U.S. soil, you can still find companies like B9 Creations, Carbon, Formlabs, Markforged, and smaller metal AM system manufacturers such as ADDiTEC, 3DEO, FormAlloy, and Xact Metal, along with a handful of desktop-grade FFF printer makers (FAME 3D / LulzBot, Airwolf 3D). I’m not sure exactly what Stratasys manufactures in the U.S.—most of their production seems to be based in Israel and other regions—and HP is similarly vague in that regard.

Among AM system manufacturers, there’s also Sciaky, though it’s a very specific case—they produce both parts and machines in equal measure.

That said, the majority of machine manufacturers are now based elsewhere—Europe, Asia (China, Taiwan, Japan), or even Australia.

As for industrial 3D printer installations, the leaders in sheer numbers are the Chinese companies UnionTech (~800 systems, mostly polymer-based but also metal PBF) and BLT (several hundred metal 3D printing systems).

American and European companies simply can’t compare or compete in that area.

So unfortunately, Terry Wohlers was right. While for a time it seemed like the winds of history were pushing things in the direction he had hoped, in the end, everything has reverted to how it was 12 years ago.

A real shame.

Atomic Layer from the Past:

05-10-2012: Michael Joyce launched a Kickstarter campaign for B9 Creator.

News & Gossip:

AddUp Inc.’s partner, Acuity Surgical Devices, received FDA 510(k) clearance for its 3D printed Ventris Interbody Fusion System, produced on the FormUp 350 LPBF system. The implant improves osteointegration and surgical outcomes, demonstrating how advanced additive manufacturing supports both innovation and regulatory compliance in spinal surgery solutions.

Thermwood Corporation has appointed Jason Susnjara as President and Jennifer Watt as Executive VP, marking a generational leadership shift. The move supports Thermwood’s strategic focus on large-scale additive manufacturing, especially in tooling and aerospace, as the company continues to evolve its hybrid 3D printing and CNC machining capabilities.

ESA has awarded Caracol a grant to lead the AIMIS LFAM project, focused on developing AI-powered large-format additive manufacturing for space. In partnership with Politecnico di Milano and OBO Space, the project aims to create autonomous, self-monitoring 3D printing systems for use in orbit and extreme environments.