The 3D Printing World Guide: FINLAND

A tour of the Finnish AM Industry

Finland is one of the most stable and innovative countries in Northern Europe. Although it has a population of just over 5.5 million, its GDP exceeds 330 billion euros, placing it among the ten most advanced economies in the European Union in terms of productivity and innovation.

Globally, Finland ranks in the fourth decade of the world’s largest economies, yet when measured by GDP per capita, it stands among the leaders—alongside countries such as Switzerland, Norway, and the Netherlands. The Finnish economy is built on high value-added production, the export of advanced technologies, a strong education sector, and a unique culture of collaboration between academia and industry.

Click to download PDF version ⤓

For decades, Finns have specialized in precision engineering, telecommunications, renewable energy, marine and shipbuilding, and materials science. The cities of Helsinki, Espoo, and Tampere form an “innovation triangle” where technology startups, research centers, and industrial plants cooperate closely with universities.

A special place in this ecosystem is held by additive manufacturing, which in Finland not only has a strong scientific foundation but also a deeply rooted industrial tradition.

The origins of the Finnish AM industry

The history of Finnish 3D printing is unique in the European context, as some of the fundamental solutions for modern additive technologies were developed precisely in this country. As early as the late 1980s and early 1990s, Finland was among the first European nations to implement industrial stereolithography (SLA) systems.

In 1989, Electrolux Rapid Prototyping imported Europe’s first SLA system manufactured by 3D Systems - just a few years after the technology debuted in the United States. Even then, 3D printing was being used by Finnish companies for rapid prototyping of components for the electronics and machinery industries.

The real breakthrough came in the 1990s, when Finnish engineer Olli Nyrhilä, working at Electrolux Rapid Prototyping, began developing the use of lasers for selective melting of metal powders. It was in Finland that the concept of DMLS (Direct Metal Laser Sintering) was born - a process now recognized as one of the cornerstones of metal 3D printing. The project was carried out in collaboration with the German company EOS.

To this day, EOS Finland Oy continues to work on the development of metal materials and process parameters, and Olli Nyrhilä is still regarded as one of the pioneers of PBF-LB/M (Powder Bed Fusion - Laser Beam / Metal) technology.

Development and structure of the modern AM industry in Finland

The modern Finnish 3D printing industry is small in absolute numbers but exceptionally advanced technologically. Finnish AM enterprises focus primarily on high-performance sectors such as marine, energy, machinery, and medicine.

Unlike in many countries where 3D printing first evolved in academia, in Finland it was industry that drove progress from the very beginning. Finnish companies quickly realized that additive technologies could serve not only as tools for prototyping but also as a means of transforming manufacturing itself. As a result, great emphasis has been placed on research into metal materials - particularly stainless steels, titanium, and aluminum alloys - and on the development of local quality standards.

A strong academic foundation gives Finland a clear advantage in additive manufacturing. Aalto, LUT, Turku, Tampere, and Oulu Universities run numerous research projects focused on laser processes, thermomechanical modeling, and new alloys for 3D printing. The first research group on AM in Finland was established at Aalto University already in 1992.

Notably, Finnish research publications on 3D printing - relative to population size - appear more frequently than in Germany or France, an impressive achievement for such a small country.

Currently, there is a dynamic increase in investments in new laboratories and AM competence centers. There is also a growing emphasis on automating data preparation, integrating with digital twins of production processes, and applying artificial intelligence to predict print quality.

Conclusion

The Finnish 3D printing industry exemplifies how a small country can play a globally significant role in the development of advanced manufacturing technologies. Through a combination of a strong research sector, open industrial collaboration, and a long tradition of technical innovation, Finland has become one of Europe’s most active centers for additive manufacturing.

It was here, more than three decades ago, that the foundations of modern metal 3D printing were laid. Today, Finland not only continues this legacy but also sets new directions for the industry - from intelligent production systems to fully automated AM lines.

In this way, the land of a thousand lakes is also becoming the land of a thousand layers both literally and metaphorically - building the next generation of the industry of the future.

FAME | Proud Sponsor of Finnish Edition

DIMECC Ltd

Åkerlundinkatu 8, 33100 Tampere, Finland

Founded: 2020

www: fame3d.fi

e-mail: fame@dimecc.com

social media: LinkedIn

Business activities: Association

Activity: World

Overview:

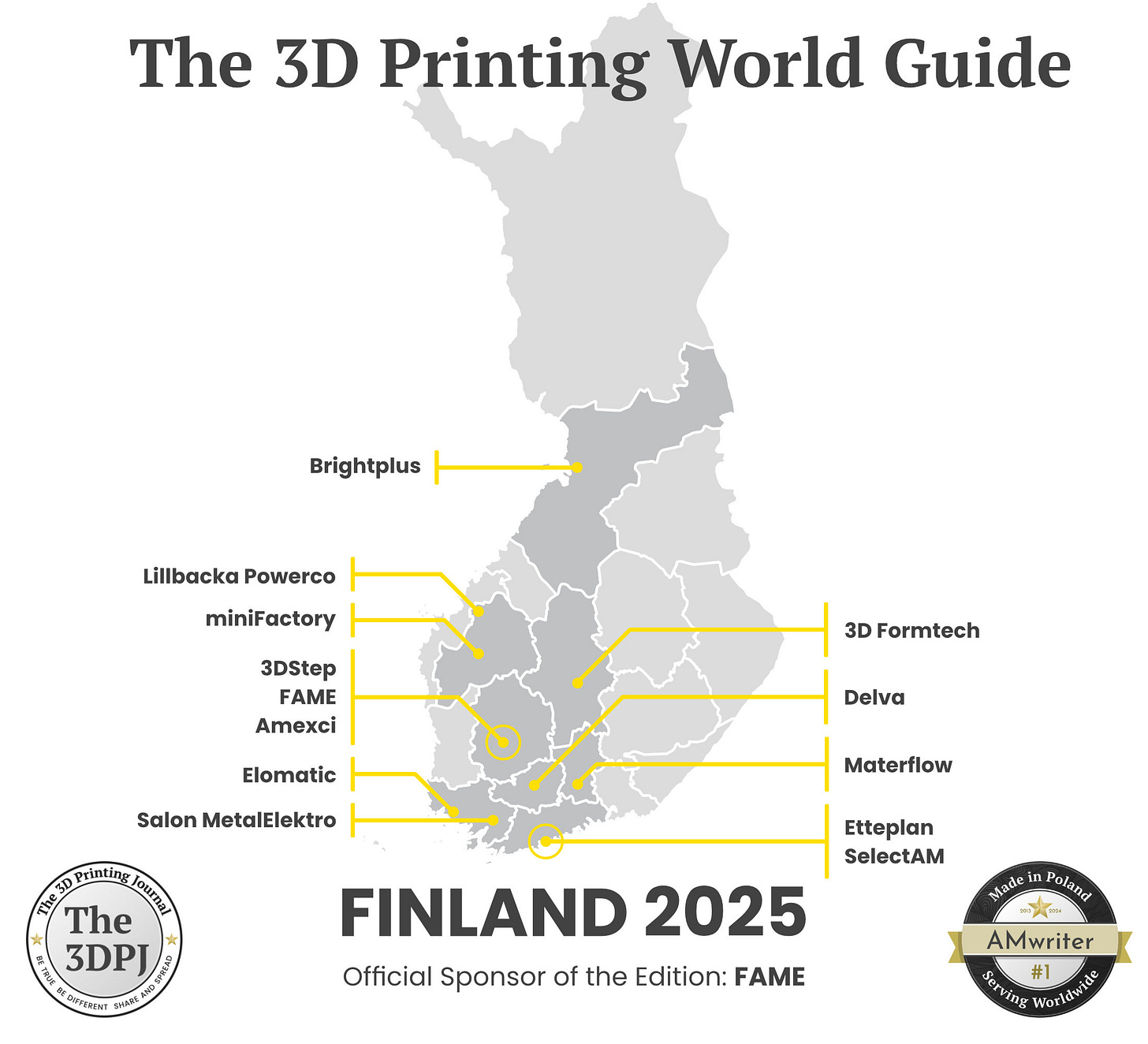

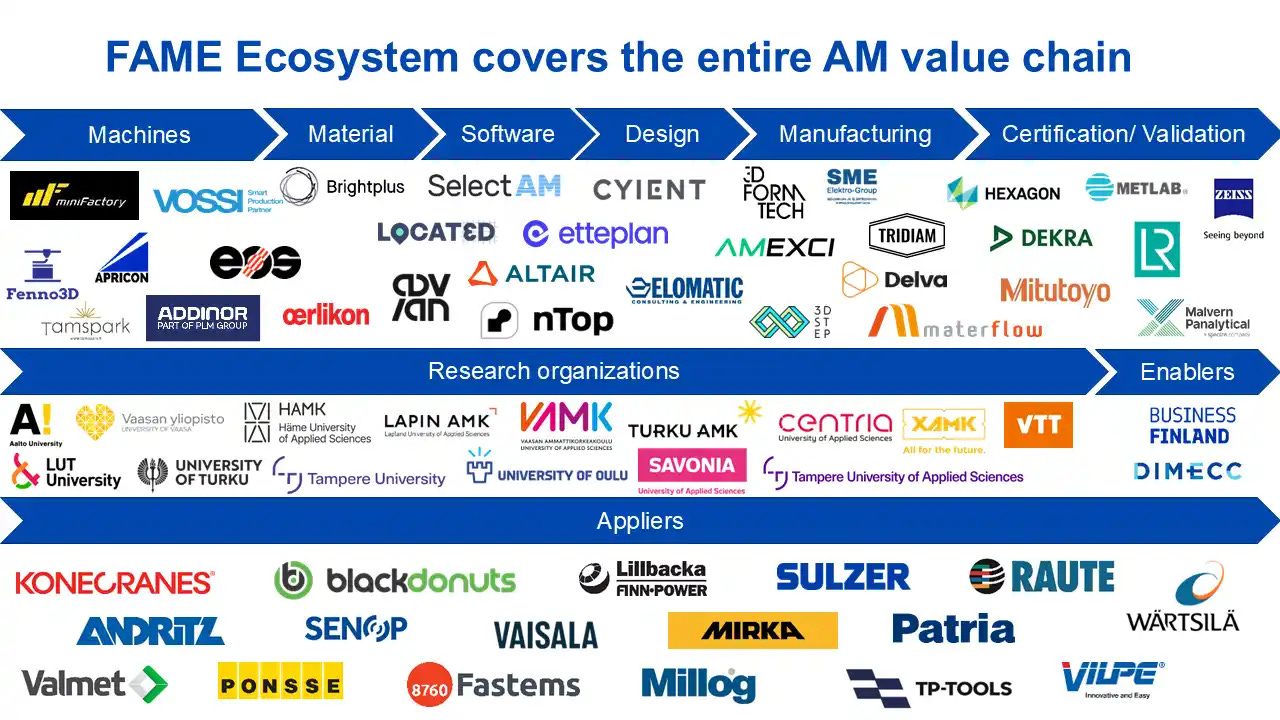

3D printing is being nationally promoted, among others, by the Finnish Additive Manufacturing Ecosystem (FAME, operated by DIMECC Ltd). FAME is a consortium of over 50 companies that covers the entire 3D printing value chain and whose vision is to create a competitive advantage for Finland through sustainable additive manufacturing.

Nearly all national 3D printing companies are involved, as well as several manufacturing industry companies that utilize 3D printing. The value chain is also supported by well-known international companies in the field, such as the software company nTop.

Through FAME, several publicly funded projects have been launched, such as the AM Campus (shared facilities for PBF-LB/M), and the DREAMS project, which studied 10,000 PBF-LB/M test specimens particularly in terms of fatigue. The FAME consortium also DED manufactured a 300-kilogram pressure vessel, which at the time was the largest DED one in Europe.

Legacy:

Finland is, relative to its population, one of the most active countries in the world from the perspective of 3D printing. For example, 3D printing research articles are published proportionally more in Finland than in Germany. One explanation for this may be that the roots of modern laser-based powder bed fusion of metals lie in Finland.

The DMLS process was developed in Finland in the early 1990s by Finnish engineer Olli Nyrhilä of Electrolux Rapid Prototyping, in collaboration with EOS. The development of EOS’s metal materials and processes still takes place in Finland under Mr. Nyrhilä’s leadership (Electro Optical Systems Finland Oy). Before EOS’s acquisition, Electrolux also had Europe’s first SLA system (3D Systems, in 1989), which already then served Finnish industry.

Today, Finland is home to AM system manufacturers and around fifteen industrial 3D printing service providers, about ten of which offer metal 3D printing services with their own equipment. There are around 60 metal 3D printers in total, almost all of which are PBF-LB/M systems. The industry in Finland is expected to grow faster than the global average.

3D FORMTECH

3D Formtech

Ahjokatu 14, 40320 Jyvaskyla, Finland

Founded: 2014

www: 3dformtech.fi

e-mail: sales@formtech.fi

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: AM Service Provider

AM services:

PBF

SLS

Activity: World

Overview:

3D Formtech helps companies in the manufacturing industry worldwide to discover the limitless possibilities of 3D printing. It is the largest industrial 3D printing company in Finland in terms of turnover, and its factory in Jyväskylä supplies a significant share of the country’s industrial 3D-printed parts.

As printing materials, 3D Formtech uses a variety of plastics and metals that can withstand even the most demanding applications - resistant to water, dirt, chemicals, sunlight, and even fire. With eight EOS machines, the company can also handle medium-series production. Its strengths include special materials such as ESD-safe polymers, flame-retardant materials, and titanium. Excellent post-processing capabilities ensure high-quality parts for customers.

3D Formtech is not just a service provider or supplier but a full-service industrial 3D printing specialist and strategic partner. It provides manufacturing, design, and finishing services with high-quality colouring and coating processes. The company meets even the most stringent quality standards.

Legacy:

3D Formtech was founded in 2014 and has grown into Finland’s largest 3D printing service provider. 19 people work in the company.

The company is focused on manufacturing demanding industrial components from both plastic and metal. The company operates internationally and has gained many customers from all over Europe.

Certificate: ISO9001

3DSTEP

3DStep Oy

Huurretie 9, 33470 Ylöjärvi, Finland

Founded: 2016

www: 3dstep.fi

e-mail: sales@3dstep.fi

social media: LinkedIn

Business activities: AM Service Provider

AM services:

SLS

MJF

PBF

Activity: Europe

Overview:

3DStep has positioned itself as a Finnish pioneer in industrial additive manufacturing. The company provides comprehensive metal and polymer 3D printing services to a diverse range of European industries, building a reputation for excellence in serial manufacturing, innovation and expert training.

Core services and capabilities:

Industrial-scale additive manufacturing with metals and polymers: 3DStep is a leader in on-demand manufacturing and digital spare parts.

Metal 3D Printing: 3DStep produces high-performance parts in a variety of industrial-grade metals. Materials include stainless and acid-proof steels (e.g., 316L), aluminum alloys (e.g., AlSi10Mg), maraging tool steels, and other specialized alloys, complemented by a full range of post-processing and finishing services.

Polymer 3D Printing: The company offers extensive capabilities in polymer AM, producing high-quality plastic components for applications ranging from functional prototypes to end-use parts.

Design, Innovation, and Training: At the forefront of AM advancement, 3DStep actively assists clients in harnessing the full potential of 3D printing through specialized services:

Design for Additive Manufacturing (DfAM): 3DStep’s experts collaborate with clients to optimize designs for 3D printing, unlocking benefits such as part consolidation, weight reduction, and enhanced performance.

Innovation and Consultation: 3DStep is a key partner in co-creation and innovation, helping industries to develop novel applications and business models centered around additive manufacturing.

Training and Education: Demonstrating a commitment to knowledge sharing, 3DStep is actively involved in educational initiatives, including specialized workshops and collaborative programsing the leap (yet), let us show you what Blackbelt can do.

Legacy:

3DStep stands out as a pioneer in Finnish industrial 3D printing, specializing in shifting manufacturing from physical warehouses to digital ones. The unique focus is on serial production and creating digital spare parts on-demand, which significantly enhances supply chain resilience for their clients.

A key achievement is their successful establishment as a profitable and comprehensive service provider offering everything from Design for Additive Manufacturing (DfAM) to finished, post-processed metal and polymer components.

3DStep is for the expertise in helping companies redesign products to unlock the full potential of 3D printing, such as improved performance and reduced weight. Their active role in the Finnish Additive Manufacturing Ecosystem (FAME) underscores their influential position in advancing the industry within the Nordic region.

AMEXCI

AMEXCI

Ajurintaival 10, 33880 Lempäälä, Finland

Founded: 2017

www: amexci.com

e-mail: info@amexci.com

social media: LinkedIn

Business activities: AM Service Provider

AM services:

PBF

Activity: World

Overview:

AMEXCI is a leading Additive Manufacturing company specializing in industrial metal 3D printing. With world-class production facilities in Sweden and Finland, the company offers expertise from early development to full scale serial production through our team of experts in design, simulation, production, and material analysis.

AMEXCI’s services include comprehensive training programs and research services that cover several areas, including different high-performance materials and consultancy on evolving topics within additive manufacturing.

Legacy:

On January 19, 2017, Marcus Wallenberg hosted a seminar in Stockholm on Additive Manufacturing, aiming to raise awareness of this disruptive technology and foster collaboration. AMEXCI AB was founded on December 1, 2017, with a mission to accelerate its shareholders’ adoption of Additive Manufacturing. Recognizing its broader potential, AMEXCI soon expanded its scope to support all companies, not just shareholders, promoting widespread adoption through collaboration.

Today, AMEXCI serves a diverse customer base across industries like space, aerospace, defense, and automotive. Offering services from R&D to production and training, AMEXCI empowers businesses to integrate 3D printing, enhancing efficiency and innovation. As a trusted partner, AMEXCI drives advancements in Additive Manufacturing, helping clients unlock new possibilities in product development and manufacturing.

BRIGHTPLUS

Brightplus Oy

Gneissikuja 5-8, 90620 Oulu, Finland

Founded: 2014

www: brightplus.com

e-mail: info@brightplus.com

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: Material Manufacturer

AM services:

FDM / FFF

Activity: World

Overview:

Brightplus transforms waste into profitable materials through a scalable innovation process. From initial research and material testing to pilot-scale production and industrial implementation, the company offers expert services at every stage. Its flexible solutions - including lab studies, small-scale production, and modular minimills - help businesses efficiently develop and commercialize sustainable materials with minimal risk and maximum impact.

By collaborating with Brightplus, companies can advance the use of renewable materials in their processes. The company’s dedicated team of experts works closely with clients to design and develop biomaterial solutions tailored to their specific requirements.

Legacy:

Brightplus was founded by a group of enthusiastic scientists and innovators who began their journey in a frozen van in Lapland, united by a shared mission to help save the planet. The founders aimed to prevent global warming, reduce pollution by removing harmful substances, and recycle industrial waste - preserving the Earth for future generations. Their vision was to create truly disruptive technological innovations at the intersection of materials science, green chemistry, synthetic biology, sustainability, and recycling.

DELVA

Delva Oy

Laajamaentie 2, 13430 Hämeenlinna, Finland

Founded: 2017

www: delva.fi

e-mail: info@delva.fi

social media: LinkedIn

Business activities: AM Service Provider

AM services:

PBF

Activity: World

Overview:

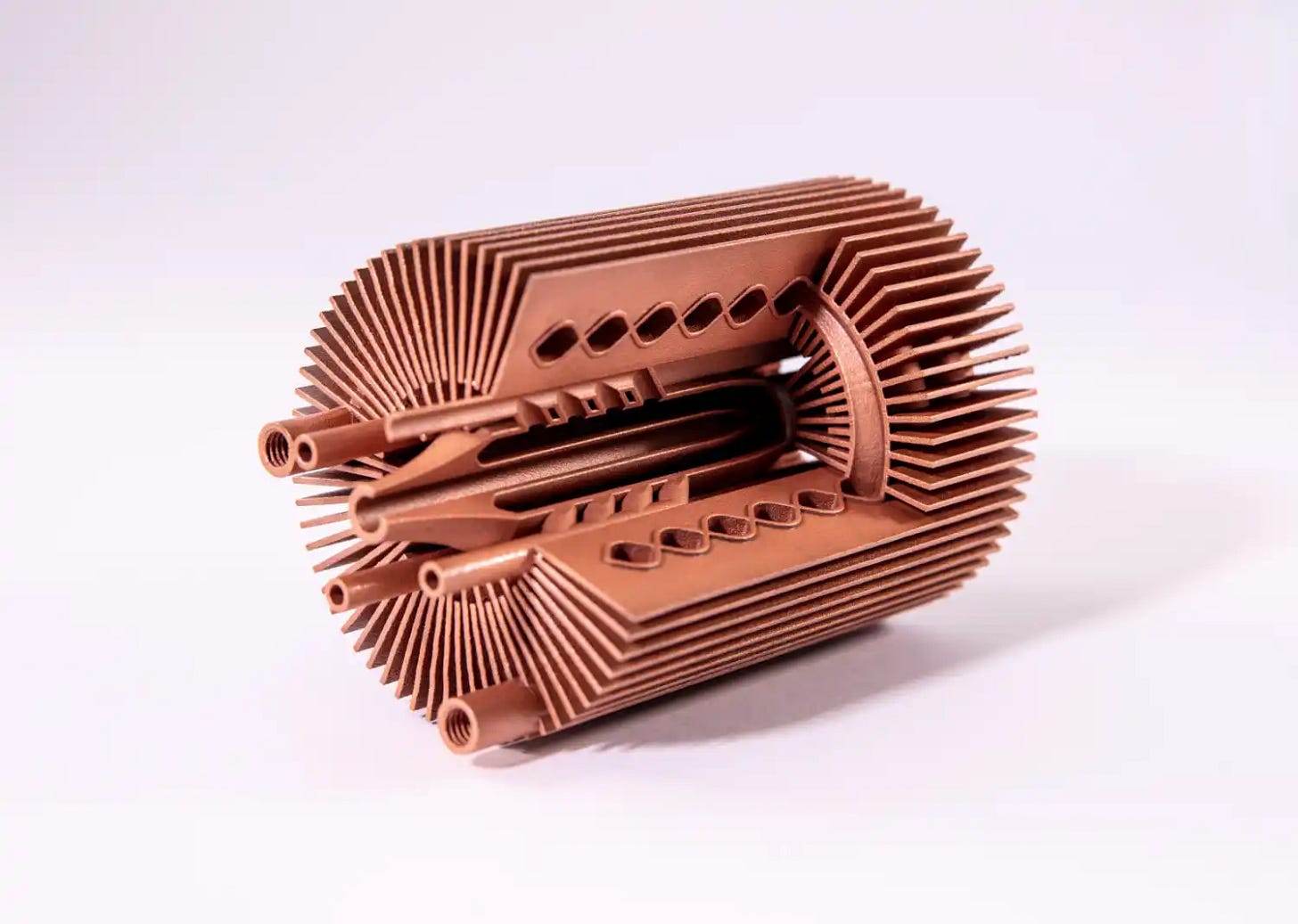

Delva Oy is the biggest metal AM service provider in Finland, focusing in 3D printing of metals. Delva has strong 3D-printing experience in nickel-alloys, copper-alloys, pure Cu, aluminium-alloys, steels and dedicated AM machine for Ti64-alloys. Currently Delva has fleet of 5 metal AM printers from EOS and AMCM. Cu-, Ni- and Al-alloys can be 3D-printed very fast by 2×1 kW AMCM industrial AM-machine added in Delva’s fleet in 2024.

In addition to 3D-printing, Delva has strong +40 years experience in in supporting global customers in their design optimization work for AM and adopting metallic 3D-printed parts to be essential parts of their final customer products and/or manufacturing equipment. Reference customers are SSAB in steel making industry and VR (Finnish Railways) in maintenance of transportation equipment.

Legacy:

Delva has been founded in 2017 by AM enthusiast and current CTO Mr. Markku Lindqvist. In 2018 Mr. Jarmo Kastell strengthened the team by bringing in his strong experience from steel making industry to Delva as CEO. At the same time Delva started own metal 3D-printing activities by investing in two EOS industrial metal 3D-printers in row. Team was developed by adding more AM specialist knowhow. And dedicated operations team lead by Mr. Marko Prinkkilä in 2023.

In early 2024 investment on new AMCM M290 2×1 kW of two 1kW lasers was done to be able to 3D-print Cu-alloys and pure Cu for high conductivity applications. And increase productivity in Ni- and Al-alloys at the same time.

The latest additions to the personnel fleet in 2025 were AM Specialist Mr. Jarno Välikangas and CCO Mr. Juha Kotila, who brought their long, professional experience from metal AM equipment and process development work to Delva in early 2025. In addition to that, Delva invested in summer 2025 in two more industrial metal 3D-printers and larger premises enabling transition to bigger equipment in future.

ELOMATIC

Elomatic Consulting & Engineering Oy

Itäinen Rantakatu 72, FIN-20810 Turku, Finland

Founded: 1970 (2020 entered the AM business)

www: elomatic.com

e-mail: info@elomatic.com

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: Consulting & Engineering

Activity: World

Overview:

Elomatic’s AM engineering helps customers optimize structures to reduce mass, energy consumption, and costs in machinery and equipment. The company has extensive experience in engineering and optimizing structures while meeting multiple performance requirements.

Together with its 3D printing partners, Elomatic offers turnkey solutions for part and structural engineering as well as rapid prototypes for product development projects. The ability to combine parts already during manufacturing enables shorter delivery times for tailored structures and reduces both the number of components and the required assembly work.

With its advanced technical analysis expertise and comprehensive engineering services, Elomatic empowers customers to rethink their products and production processes.

Legacy:

Elomatic has decades of experience in performing demanding FEM and CFD analyses, applying these methods to optimize structures. Since 2020, the company has expanded its expertise in additive manufacturing (AM) technologies, recognizing their value in producing complex parts and structures. Additive manufacturing is now an integral part of Elomatic’s mechanical design services.

Elomatic is an international consulting and engineering company that provides high-level expert services, products, and turnkey solutions for the process, machinery, marine, energy, and pharmaceutical industries. The company is committed to continuous improvement and sustainable development, designing solutions that enhance the wellbeing of people and the environment.

Founded in 1970, Elomatic employs around 1,300 professionals and serves customers in more than 80 countries worldwide.

ETTEPLAN

Etteplan Oyj

Tekniikantie 4 D, 02150 Espoo, Finland

Founded: 1983

www: etteplan.com

e-mail: info@etteplan.com

social media: LinkedIn | Instagram | YouTube

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

PBF

DED / WAAM

BinderJetting

Activity: World

Overview:

Etteplan is not just another player in additive manufacturing — the company is a team of problem-solvers, designers, and innovators. With more than 4,000 experts across nearly every industry, Etteplan brings deep domain knowledge to additive manufacturing, ensuring that solutions are not only printable but also impactful in their end use.

The company’s Advanced Manufacturing & Optimization (AMO) team specializes in Design for Additive Manufacturing (DfAM), AM consulting, and training. Etteplan helps companies unlock the potential of 3D printing by:

Identifying the right applications and pairing them with the appropriate AM technology,

Overcoming technical and organizational barriers,

Creating innovations that generate real business value.

What sets Etteplan apart is the strength of its engineering analysis and simulation capabilities. By combining these with AM expertise, the company delivers optimized, validated designs that perform reliably in real-world conditions — an approach it calls simulation-driven design.

Etteplan connects additive manufacturing with the broader engineering ecosystem, ensuring that customers receive solutions that are robust, manufacturable, and tailored to their specific industry.

Legacy:

Founded in 1983 in Finland, Etteplan has grown into a global engineering services company with more than 4,000 experts supporting customers across aerospace, automotive, energy, machinery, and medical technology. Etteplan’s legacy is built on solving complex engineering challenges and applying new technologies to create smarter, more sustainable solutions.

Additive manufacturing became a natural extension of this journey. Etteplan was among the first engineering companies in Northern Europe to establish a dedicated AM team, developing capabilities in Design for Additive Manufacturing (DfAM), simulation-driven optimization, and AM consultation. Over time, Advanced Manufacturing & Optimization (AMO) team has supported customers from feasibility studies to industrialization, while training organizations to adopt AM with confidence.

Today, Etteplan is the leading engineering office with AM know-how in the Nordics, where the expertise lies in bridging technology with industry reality—delivering optimized designs, innovative applications, and strategies that stand up to real-world performance.

LILLBACKA POWERCO

Lillbacka Powerco Oy

Konepajantie 4, 62300 Härmä, Finland

Founded: 1969 (2018 entered the AM business)

www: finnpower.fi

e-mail: powerco@lillbacka.com

social media: LinkedIn | Facebook | YouTube

Business activities: AM Service Provider

AM services:

FDM / FFF

PBF

Activity: World

Overview:

Lillbacka Powerco is the manufacturer of market-leading Finn-Power crimping machines. In addition to its high-quality crimping equipment, the company offers industrial-grade 3D printing / Additive Manufacturing services to support a wide range of customized tooling and subcontracting needs. Alongside its AM services, Lillbacka Powerco provides 5-axis machining and comprehensive post-processing of printed parts.

Legacy:

Lillbacka Powerco’s commitment to innovation, quality, and customer satisfaction has been the key to its success for more than 50 years in producing crimping machines. Since 2018, the company has applied the same principles to offer industrial-grade metal 3D printing services.

Lillbacka Powerco Oy specializes in high-quality metal additive manufacturing solutions for diverse industrial needs. The company uses ultra-high-strength maraging steel, suitable for the most demanding applications.

MATERFLOW

Materflow Oy

Ilmarisentie 13, 15210 Lahti, Finland

Founded: 2013

www: materflow.com

e-mail: info@materflow.com

social media: LinkedIn

Business activities: AM Service Provider

AM services:

SLS

Activity: Europe

Overview:

Founded in 2013, Materflow is one of the leading additive manufacturing and 3D printing technology service providers in the Nordic region. The company’s clients operate in the industrial sector, aiming to develop their products, supply chains, and processes toward more profitable and sustainable solutions.

In addition to 3D printing services, Materflow helps customers harness the full potential of additive manufacturing in their business operations, product development, and design and engineering processes.

Legacy:

Out-of-the-box thinking since 2013. Flexible partner for component manufacturing, and starting new production with special materials. Achieved 100% usage efficiency on PA12 material.

MINIFACTORY

miniFactory Oy Ltd

Tiedekatu 2, 60320 Seinäjoki, Finland

Founded: 2012

www: minifactory.fi

e-mail: sales@minifactory.fi

social media: LinkedIn | YouTube

Business activities: Hardware Manufacturer and AM Service Provider

AM services:

FDM / FFF

Activity: World

Overview:

miniFactory is a Finnish 3D printing solution provider specializing in high-performance polymers and composites. Founded in 2012 and headquartered in Seinäjoki, Western Finland, the company designs and manufactures all its products in Finland, ensuring uncompromising quality and reliability.

miniFactory’s technology is developed for industries that demand extreme material performance and certified quality, including aerospace, defense, energy, and transportation. With an open material system, customers gain flexibility and reduced operating costs while maintaining reliability and compliance with industry standards.

Every miniFactory system features an integrated quality assurance platform that verifies the consistency of printed parts to ensure they meet strict performance requirements. This capability positions additive manufacturing as a viable alternative to traditional methods in critical applications where traceability and reliability are essential.

With proven technology, global reach, and a strong industrial focus, miniFactory serves as a trusted partner for companies seeking a complete additive manufacturing solution.

Legacy:

Since its founding in 2012, miniFactory has pursued a clear mission: to make industrial 3D printing with high-performance polymers accessible, reliable, and certifiable. Today, more than 100 miniFactory systems are installed across Europe, serving leading companies in the aerospace, defense, energy, and rail sectors. While the company’s compact and efficient technology is valued across industries, it has gained particular recognition in defense applications and spare part production for the railway sector.

Quality assurance has been at the core of miniFactory’s innovation. The company’s integrated monitoring system ensures that every part is produced with full traceability and documented reliability — features that distinguished miniFactory from competitors early on.

A major milestone was achieved at Deutsche Bahn’s Neumünster AM facility, which became one of the first sites in the world to receive certification under the ISO/ASTM 52920:2023 standard by TÜV NORD GROUP. This certification process confirmed the compatibility of miniFactory Ultra printers with the highest global benchmark for additive serial production, reinforcing the company’s position as a trusted technology leader in high-performance polymer 3D printing.

SALON METALELEKTRO

Salon Metalelektro Oy

Kiertokatu 21, 24280 Salo, Finland

Founded: 1990 (2020 entered the AM business)

www: smegroup.fi

e-mail: sales@salonmetalelektro.fi

social media: LinkedIn

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

PBF

Activity: World

Overview:

Salon Metalelektro is a contract manufacturer specializing in demanding mechanical components. The company operates a metal 3D printer dedicated to titanium and aluminum printing.

With a diverse and modern machinery base, extensive experience from a wide range of complex projects, and a deep understanding of customer needs, Salon Metalelektro has become a trusted partner for clients with high technical requirements.

The company’s production facilities include nearly 50 CNC machine tools, a wide range of finishing capabilities, as well as one metal 3D printer and approximately 15 polymer 3D printers. This enables Salon Metalelektro to provide complete contract manufacturing services — from product design to finished components.

Legacy:

Salon Metalelektro was founded in 1990 and has remained under the same ownership ever since. The company is privately owned and specializes in the production of demanding machined components and contract manufacturing for numerous international clients.

With highly automated production and the use of the latest technologies, Salon Metalelektro has established itself as a competitive manufacturer, even for mass-produced products.

SELECTAM

SelectAM

Lapinlahdenkatu 16, 00180 Helsinki, Finland

Founded: 2020

www: selectam.io

e-mail: hi@selectam.io

social media: LinkedIn

Business activities: Software Developer

Activity: World

Overview:

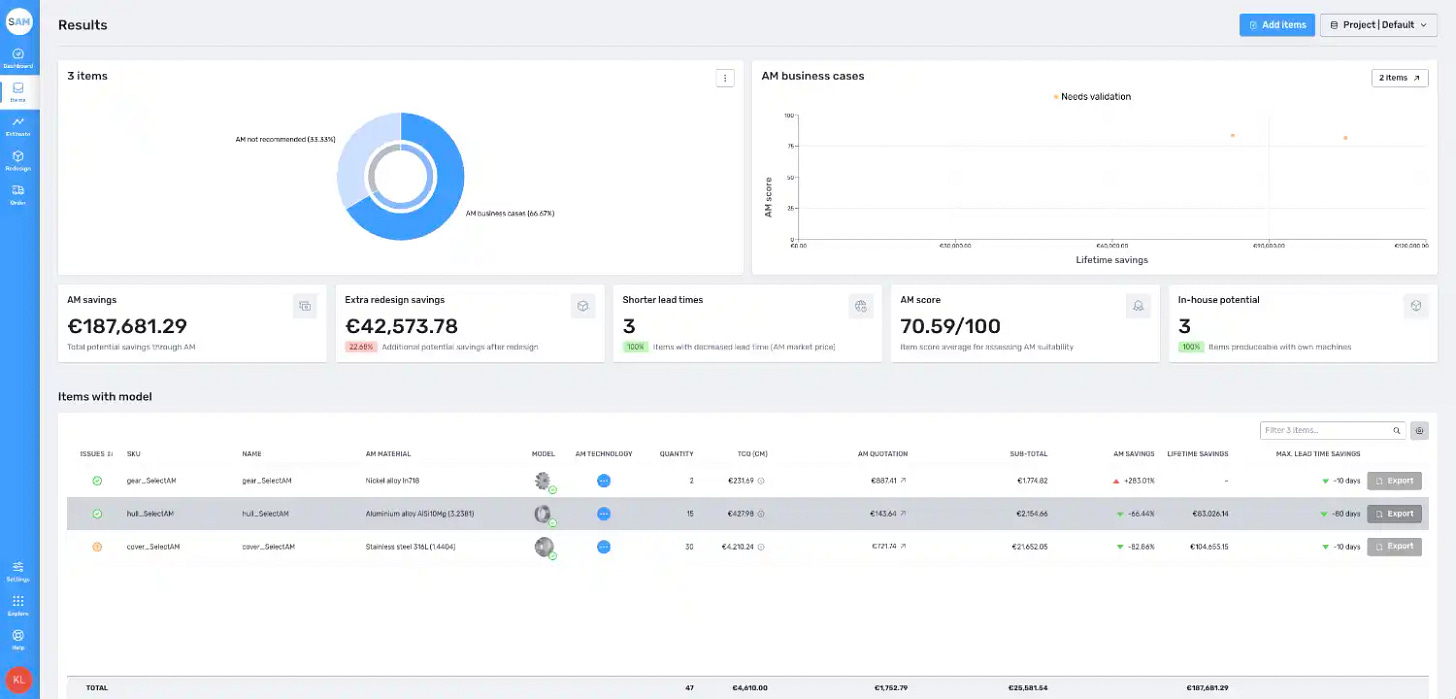

SelectAM’s AI-powered „AM co-pilot” software fundamentally changes how companies approach additive manufacturing by automating the part identification process. Their specialisation is screening large digital inventories (without CAD models) for viable business cases, replacing a slow, manual approach. The platform is highly customisable, allowing users to configure a bespoke machine and material portfolio with specific parameters, ensuring accurate evaluations based on their unique capabilities.

For OEMs and AM appliers, this provides a clear, data-driven path to integrate AM, identifying parts suitable for cost reduction and improved lead times. Also, their AI-based engines like the redesign impact analysis, or the 2D drawing to 3D model conversion tool are available for faster digitalisation and decision making.

For 3D printing service bureaus, the software is a powerful quotation tool. It enables them to provide rapid, accurate quotes by instantly analysing part files and simulating production, reducing quotation times by up to 90% and significantly boosting their operational efficiency.

Legacy:

SelectAM’s unique AI-powered software is a critical solution for the additive manufacturing (AM) industry. With a growing customer base of hundreds of users, the platform automates a key bottleneck, saving hundreds of man-hours by screening tens of thousands of parts at once. This top-down process provides a data-driven path to adoption, accelerating a company’s return on investment (ROI) in AM.

By incorporating a customisable material and machine portfolio, the software enables OEMs to achieve significant cost savings and reduced lead times, while empowering service bureaus with rapid, accurate quotes. The software’s robust capabilities have been proven in the defence sector.

SelectAM was chosen for a defence accelerator, and its system has been tested against NATO standards, underscoring its reliability for critical military applications.