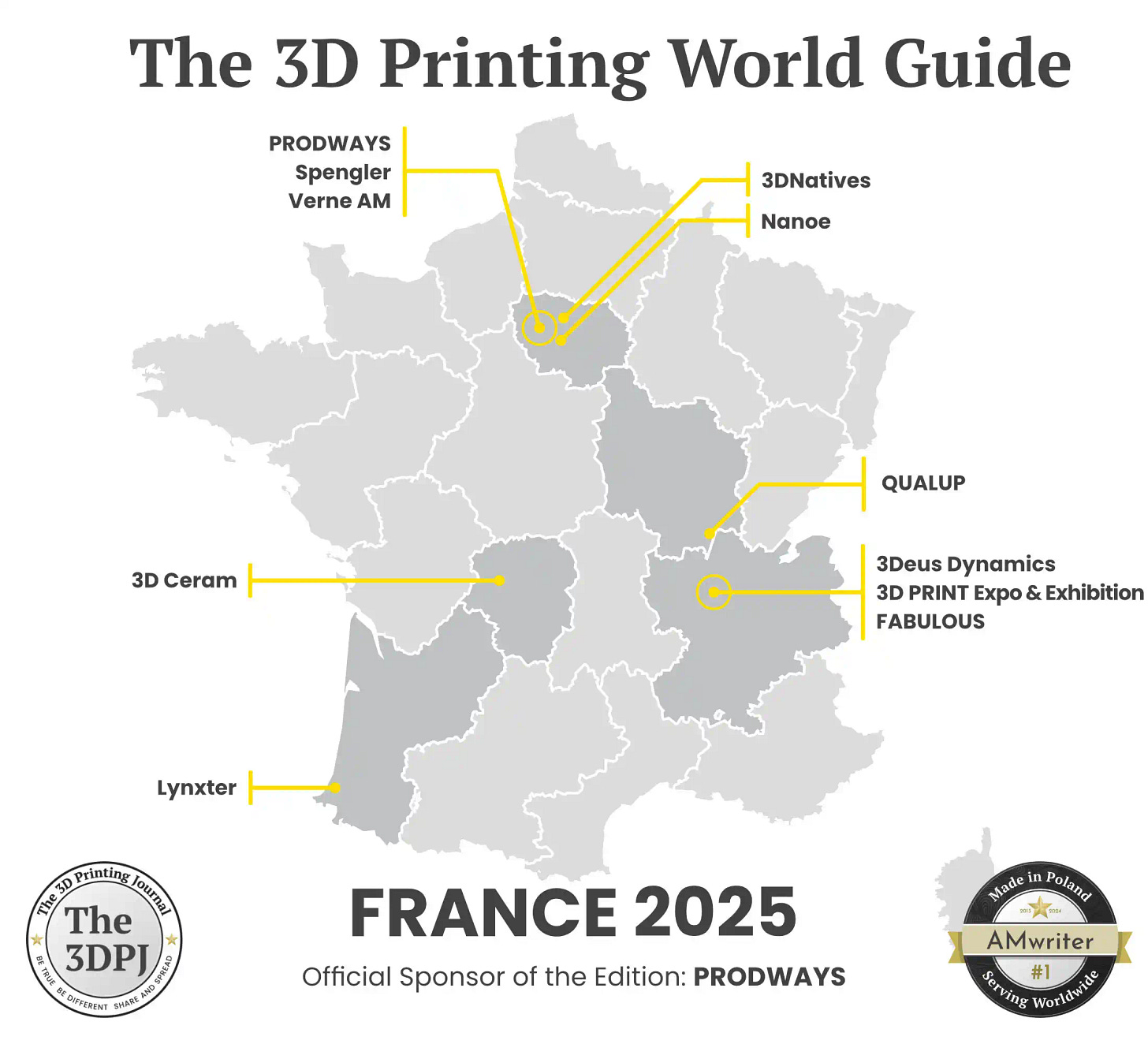

The 3D Printing World Guide: FRANCE

A tour of the French AM Industry

The following foreword is authored by the one and only Mr. Filippos Voulpiotis, Chief Business Officer of 3DNatives - one of the largest and most important AM media in the world.

In France, when we talk about 3D printing, we are not just talking about a technology; we are talking about history, innovation, and a little of that iconic French charm.

France, being one of the world’s largest economies and a usual suspect when it comes to adopting new technologies, wasn’t absent from 3D printing’s first steps. Back in the 1980s, when 3D printing was still the province of science-fiction dreams, with its storied tradition of engineering, France was diving in. With institutions like École Polytechnique tinkering on early machines and the French National Centre for Scientific Research (CNRS) playing a pivotal role in advancing 3D printing through groundbreaking research, fostering interdisciplinary collaborations, and pushing the boundaries of materials science.

Click to download PDF version ⤓

Change doesn’t happen overnight of course, but over the decades more and more applications have found their way to traditional production. French OEMs, such as Airbus and Safran, have been leading the industry in using 3D-printed metal components that make planes lighter, greener, and cooler.

This was while the luxury sector — always the one at the cutting edge of what’s next — began to employ 3D printing to make everything from haute couture to fine jewelry. Think a 3D-printed cast of a recognizable Chanel perfume bottle or a piece of experimental Hermès jewelry that appears to be from 3000 A.D. Only in France, right?

PRODWAYS: sponsor of the French Edition of The 3D Printing World Guide

Of course, there have been plenty of obstacles, too. There were challenges, such as learning how to optimize designs and navigate challenging materials. But, as the French say, “C’est en forgeant qu’on devient forgeron” (It’s by forging that one becomes a blacksmith). And forge they did, transforming adversity into opportunity. Companies like Dassault Systèmes have done immense progress in the field of design digitalization and others, like Michelin, have led exploration efforts on next-generation 3D-printed tires.

Today, France is one of the world leaders in Additive Manufacturing, with a rich ecosystem that touches aerospace, healthcare, transportation and -you guessed it- fashion. From government-sponsored initiatives to community maker movements, innovation is everywhere.

France’s 3D printing journey has been one of curiosity, collaboration, and tons of French flair. It’s about building wild ideas, one layer at a time—and really, what’s more fun than that?

by Filippos Voulpiotis (3DNatives)

Filippos Voulpiotis is Chief Business Officer of 3DNatives, associated with it since 2018. 3Dnatives is the largest international online media platform on 3D printing and its applications. With its in-depth analysis of the market, 3Dnatives gets over 1.3 million unique visitors per month and is currently available in English, French, Spanish, German, and Italian.

PRODWAYS | Proud Sponsor of French Edition

Prodways Machines

43 Av. des 3 Peuples Bâtiment G, 78180 Montigny-le-Bretonneux, France

Founded: 2007

www: prodways.com

e-mail: contact@prodways.com

social media: LinkedIn | YouTube

Business activities: Hardware Manufacturer and Material Manufacturer

AM services:

SLA / DLP

Distribution:

CERAM PRO 365

CERAM PRO 385+

CERAM PRO 405+

DENTAL PRO 200

DENTAL PRO 10

Activity: World

Overview:

Prodways Machines, part of the Prodways Group, is a leading provider of industrial and professional 3D printing solutions. Prodways offers a fully integrated approach, covering software, printers, materials, parts, and services. As a pioneer in ceramic 3D printing, the company drives innovation through strategic partnerships and advanced R&D, specializing in DLP 3D printers for industrial applications. With a global presence and over 200 machines installed, Prodways technology enables high-performance manufacturing, producing thousands of parts daily. Key applications include:

✔ Investment Casting

✔ Core Foundries

✔ Aerospace & Defense

✔ R&D

✔ Automotive

Legacy:

Prodways Machines, part of the Prodways Group, has been a key player in industrial 3D printing since its inception. The journey began in 2007 with the creation of MOVINGLight®, a patented DLP technology known for its precision and efficiency. In 2013, Groupe Gorgé acquired Phidias Technologies, renaming it Prodways, marking a major step in its expansion.

Over the years, Prodways Machines has developed a fully integrated approach, covering software, materials, and multi-technology 3D printing solutions. The company is a pioneer in ceramic 3D printing and has an exclusive partnership with SINTX for advanced ceramic slurries. It also manufactures its own high-performance resins, ensuring superior quality and reliability.

Prodways Machines delivers innovative solutions for the industry alongside key sectors such as aerospace, automotive, and healthcare. Through continuous innovation, strategic partnerships, and a strong global presence.

3DCERAM

3DCeram SAS

4, rue du Parc de Maison Rouge 87270 Bonnac-La-Côte, France

Founded: 1997

www: 3dceram.com

e-mail: info@3dceram.com

social media: LinkedIn | YouTube

Business activities: Hardware Manufacturer

AM services:

FDM / FFF

SLA / DLP

Distribution:

C101 EASY

C1000 FLEXMATIC

C3601 ULTIMATE

M.A.T.

ALUMINA

Activity: World

Overview:

3DCeram is a turnkey provider specializing in 3D printing ceramics, consistently innovating to offer a range of advanced 3D printers for the development and large-scale production of both small and large ceramic components. Leveraging a cutting-edge 'top-down' printing technology, 3DCeram ensures precision and efficiency in its additive manufacturing processes.

The company features the C1000 FLEXMATIC, an industrial printer designed as a semi-automated production line to meet industrial needs, and the C3601 ULTIMATE, specifically designed to produce large parts in a single dense piece or a high volume of small dense parts, thanks to its exceptionally large printing platform.

Recently, 3DCeram introduced CERIA, an artificial intelligence solution that helps manufacturers adopt additive manufacturing for cost-efficient production. This AI also facilitates the technological transfer necessary for industrialists to produce using 3D printing.

Legacy:

At 3DCeram, the company is driving innovation in the 3D ceramic printing process through the integration of automation, enabled by 3DCeram’s top-down stereolithography (SLA) technology.

Thanks to this cutting-edge approach, 3DCeram can automate several critical tasks within the printing process, ensuring efficiency and meeting the needs of industrial applications.

Automation is essential for scaling production, and it’s not something every technology can achieve. 3DCeram’s top-down SLA process eliminates the need for support structures, allows for uniform shrinkage during firing, and delivers unmatched precision — key benefits for industries such as aerospace, biomedical, and automotive.

Additionally, 3DCeram’s embedded artificial intelligence (AI), CERIA, optimizes the 3D ceramic printing process, combining with automation to pave the way for the industrialization of additive manufacturing in technical ceramics.

These breakthroughs demonstrate 3DCeram’s commitment to advancing 3D ceramic printing technology, providing robust, efficient solutions for today’s industrial challenges.

3D PRINT CONGRESS & EXHIBITION

3D PRINT Congress & Exhibition

Eurexpo – Lyon – France (Avenue Louis Blériot - 69680 Chassieu)

Founded: 2014

www: 3dprint-exhibition-lyon.com

e-mail: stephanie.collot@infopro-digital.com

social media: LinkedIn | YouTube

Business activities: Congress & Exhibition

Activity: World

Overview:

As the only professional event in France exclusively dedicated to additive manufacturing, 3D PRINT has established itself as the leading event in France. Year after year, this trade show has gathered together the entire 3D printing ecosystem, from major industrial players to startups. Beyond the exhibition area with many exhibitors, it serves as a unique networking platform where companies, experts, and decision-makers can explore the latest trends and solutions in additive manufacturing through its conference program and high-level panel discussions.

At the forefront of trends and innovations, 3D PRINT is now recognized as the national leader among the top three most influential events in the industry at the European level. It provides a premier showcase for technological advancements and industrial applications in additive manufacturing.

Legacy:

In 2025, two new highlights:

🔹 Thematic Visit Tours

Four thematic tours will guide visitors through the latest innovations in aerospace, automotive, healthcare & medical, and sports & leisure. By following these tours, participants will gain direct access to the most recent solutions offered by exhibitors and engage with experts shaping the future of their industries.

🔹 Business Connect

Developed in partnership with France Additive, aims to facilitate networking between industry players. This dedicated space will provide an ideal setting for companies to bring their additive manufacturing projects into reality and accelerate their growth.

3DEUS DYNAMICS

3Deus Dynamics

466 rue des Mercières, 69140 Rillieux-La-Pape, France

Founded: 2020

www: 3deusdynamics.com

e-mail: celia.halimi@3deusdynamics.com

social media: LinkedIn | YouTube

Business activities: AM Service Provider

AM services:

LDM (Liquid Deposition Modeling)

Dynamic Molding

Activity: World

Overview:

3Deus Dynamics revolutionizes manufacturing with its patented Dynamic Molding process, enabling 3D printing of high-performance soft materials, silicone, and polymer parts. 3DDeus’s unique approach eliminates tooling constraints, offering unmatched design flexibility and production scalability.

Specializing in aerospace and medical applications, the company delivers certified, high-precision parts that meet the most demanding industry standards, including ISO 13485 and ISO 9100 (in progress). 3Deus’s industrial-scale production facility in Lyon integrates cutting-edge technology to manufacture components up to 1 meter in size, ensuring rapid, cost-effective, and high-quality production.

With a strong R&D foundation and collaborations with leading research institutions, the company pushes the boundaries of advanced materials for sealing, shielding, and structural applications.

Legacy:

Founded in 2020, 3Deus Dynamics pioneered the patented Dynamic Molding technology, revolutionizing additive manufacturing for soft materials. By eliminating tooling constraints, 3Deus introduced a new era in high-performance silicone and polymer 3D printing. The company's breakthrough approach quickly gained recognition, securing ISO 13485 certification in 2023 for medical applications and expanding into aerospace with ISO 9100 certification in progress.

In just a few years, 3Deus established an industrial-scale production site in Lyon, collaborated with top-tier research institutions, and engaged with major industry leaders. The company's innovations have been showcased at leading trade fairs, including CES and the Paris Air Show, demonstrating the transformative potential of Dynamic Molding™.

Today, 3Deus continues to push the boundaries of materials science, delivering certified, scalable, and cost-effective solutions for the most demanding applications.

3DNATIVES

3Dnatives

157 blvd MacDonald, Paris 75019, France

Founded: 2014

www: 3Dnatives.com

e-mail: filippos@3dnatives.com

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: News Media

Activity: World

Overview:

3Dnatives is a leading global platform dedicated to 3D printing and additive manufacturing, attracting over 1 million visitors monthly. It serves as a trusted resource for professionals, including those from OEMs, who rely on its in-depth news, market insights, and expert analysis to stay ahead in the industry.

Offering a mix of articles, reports, and webinars, 3Dnatives bridges the gap between technology providers and end-users, fostering innovation and knowledge-sharing. It is a go-to hub for understanding trends and advancements in 3D technologies.

Legacy:

3Dnatives is the largest media in the additive manufacturing space, consistently getting over 1,000,000 people visiting the platform every month. The platform is available in English, French, German, Spanish and Italian, where the content is produced by creators from the respective markets, making the connection between audience and content smooth and natural.

Additionally, 3Dnatives owns ADDITIV, a virtual event brand hosting events available for all professionals interested in the world of AM. Last but not least, 3Dnatives was acquired by the Society of Plastics Engineers (SPE) back in 2023, widening its impact to the North American markets and the polymer world overall.

FABULOUS

FABULOUS

2 avenue Roger Salengro 69120 Vaulx-en-Velin, France

Founded: 2014

www: fabulous.com.co

e-mail: arnault@fabulous.com.co

social media: LinkedIn

Business activities: Material Manufacturer

AM services:

SLS

PBF

Distribution:

BLUECARE

DETECT

ACTIVE

Activity: World

Overview:

FABULOUS is an expert company in powder materials for 3D printing, supplying polymer materials globally. Its powders are compatible with 95% of SLS 3D printers on the market.

Specializing in PA11, FABULOUS is both a leading supplier and developer of new technical materials based on PA11.

The company innovates in a market now focused on production by developing technical materials that meet the application needs of end users. Its flagship materials include BLUECARE and DETECT for the food and pharmaceutical industries, and ACTIVE for the drinking water industry, all with the highest certifications required for these technical sectors.

Additionally, FABULOUS is actively developing new materials for high-value markets, with ongoing advancements targeting the electronics and defense sectors, as well as segments for industrial and desktop 3D printers.

This commitment to innovation ensures that FABULOUS remains at the forefront of the 3D printing industry, continuously expanding its offerings to meet the evolving demands of various industries.

Legacy:

The company FABULOUS is renowned for being the first to develop patented materials compliant with food contact regulations for powder bed technologies. These materials also feature detection functionalities essential for safety in food and pharmaceutical production lines: optical detection with a blue safety indicator within the material's mass and metal detection using a composite polymer magnetite material.

The materials are developed from bio-based PA11, granting them the highest food contact certifications (EU 1935-2004 / 10-2011 & FDA CFR 21). Additionally, FABULOUS is the first material development company to make its food-safe DETECT material available on the Formlabs Fuse1+ 3D printer since it was opened to third-party materials (Open materials mode).

LYNXTER

LYNXTER

Technocité – Atelier 4, 9 Rue Pierre Georges Latecoere, 64100 Bayonne, France

Founded: 2016

www: lynxter.fr

e-mail: sales@lynxter.fr

social media: LinkedIn | YouTube

Business activities: Hardware Manufacturer, Material Manufacturer and AM Service Provider

AM services:

FDM / FFF

Distribution:

Lynxter

COP Chimie

Synthene

Activity: World

Overview:

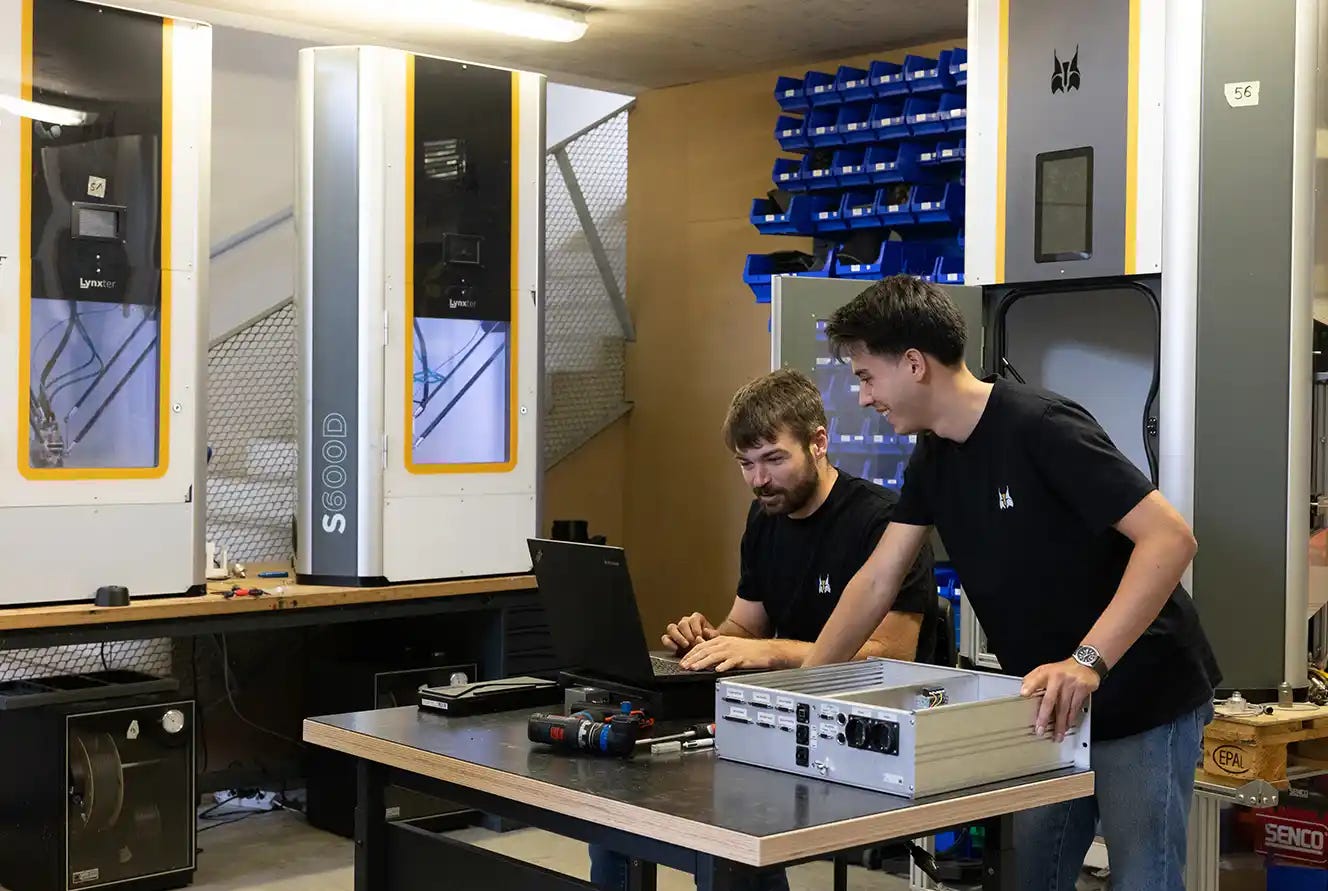

Lynxter is an industrial 3D printer manufacturer and a global leader in elastomer 3D printing. Based in France with fewer than 50 employees, the company develops machines, materials, and software. Recognized for its expertise in silicone additive manufacturing, Lynxter has received multiple innovation awards and actively contributes to scientific advancements.

Its product range includes the S600D, a modular, universal 3D printer, and various versions of the S300X, a high-performance, specialized IDEX 3D printer capable of printing silicone, polyurethane, thermoplastics, and even ceramics. Lynxter offers an open ecosystem with industrial standards in service, quality, and performance.

Operating internationally, the company serves leading industries in aerospace, healthcare, defense, luxury, and scientific research.

Legacy:

Driven by young engineers from ENIT who wanted to shake up the norms, Lynxter has reinvented local manufacturing by creating ultra-versatile 3D printers capable of producing virtually anything in a decentralized, fast, and eco-friendly manner.

With an unrivaled catalog of materials—particularly its world-leading expertise in 3D printing elastomers (medical and industrial silicone)—Lynxter supports Airbus, Renault, Sanofi, as well as the luxury and defense sectors across Europe, North America, and Asia.

Their technology enhances responsiveness, fosters innovation, and reduces carbon footprints. Entirely designed and manufactured in Bayonne, in the Basque Country, this French-made innovation exemplifies a new economic and ecological model, directly addressing the challenges of sovereignty and customization.

NANOE

Nanoe

6 rue des Frênes, 91160 Ballainvilliers, France

Founded: 2008

www: nanoe.com | zetamix.com

e-mail: contact@nanoe.com

social media: LinkedIn | YouTube

Business activities: Material Manufacturer

Distribution:

Zetamix ceramic and metal filament

Zetamix Epsilon filament for RF applications

Activity: World

Overview:

Nanoe is a supplier of advanced ceramic and metal materials. Through its brand Zetamix, Nanoe offers filaments for 3D printing of ceramic and metal parts, and with partners, the company also supplies debinding and sintering equipment for these. Nanoe also launched a line of ceramic-filled filament for RF applications under the brand Zetamix Epsilon.

Legacy:

Nanoe was founded in 2008 by 3 engineers. The main focus of Nanoe for the first 10 years was the development of advanced ceramic raw materials for traditional processes. In 2018, Nanoe launched Zetamix brand of ceramic and metal filaments, since them became the leader in ceramic and metal FFF filaments.

QUALUP

QUALUP SAS

42, Rue du Château, 71260 Lugny, France

Founded: 2010

www: qualup.com

e-mail: info@qualup.com

social media: LinkedIn

Business activities: Hardware Manufacturer

AM services:

FDM / FFF

Activity: Europe

Overview:

Manufacturer of high temperature 3D printer designed to work with high-performance materials like Polycarbonate (PC), PEI 9085, PEI 1010, PEKK, PEAK, PPSU. At the same time, it offers a range of exceptional features.

Large print volume: 400 x 400 x 400 mm, with other sizes available on request.

Ultra fast heating time: the adaptive chamber ensures minimal warm-up time, so the printjobs start quickly (7 min. heating time for PEI1010 -220°C)

High temperature printhead camera: a camera in a high-temperature enclosure which offers exceptional image quality and nozzle visualization.

Legacy:

Original ideas that are very different from the others. One of Qualup’s greatest advantages is innovation, creativity, and true out-of-the-box thinking. Qualup is one of the first companies in the global AM industry to develop:

variable HT build chambers (heats in minutes)

laminar flow chamber

rotating pellet/filament heads

HT camera with zoom on the nozzle.

These and many other unique functionalities, combined with Qualup’s high-performance 3D printers, make the company’s offering exceptional in the entire AM market.

Qualup has four decades of experience. QUALUP SAS created the first proprietary 3D printers back in 2011, consistently pushing boundaries in FFF technology. Thanks to the company’s transparency, agility, and integrity towards its customers, major and established industrial enterprises use QUALUP SAS machines on a daily basis. Leveraging its experience and skills, the Qualup team produces machines that meet the highest standards and regulations required by modern companies.

SPENGLER

SPENGLER

52 Rue Pierre Curie, 78370 Plaisir, France

Founded: 2021

www: spengler.tech

e-mail: info@spengler.tech

social media: LinkedIn

Business activities: Hardware Manufacturer and Distributor

Distribution:

IntegrAM suite

Activity: World

Overview:

Spengler specializes in automated post-processing solutions for plastic (SLS, MJF) and metal (SLM, MBJ, DMLS), optimizing efficiency, quality, and sustainability.

The IntegrAM suite covers the entire workflow:

DCK Series for automated decaking, depowdering, and powder recovery, VibroBLAST for gentle depowdering and pre-finishing, and SurfPro MF for precision microfluid surface finishing.

For surface enhancement, SurfPro SD steam dyeing enables eco-friendly mass coloring, while Ecosonic ultrasonic cleaning ensures medical and food-grade part cleanliness. SVR powder sieving systems support material reuse in SLS/MJF processes.

Spengler's Systems Key Advantages:

Automation & Cost Efficiency: Reduces manual labor and increases consistency in post-processing.

Innovative Surface Finishing: The Microfluid technology allows precise, non-destructive polishing.

Eco-Friendly Dyeing: Steam-based coloring reduces water and dye consumption by 90% and 95%, respectively.

ROI-Driven Solutions: Automated systems, such as the DCK 01, provide rapid return on investment (e.g., break-even in 7-12 months depending on production volume).

Legacy:

The Spengler team has driven additive manufacturing innovation for over a decade. Their journey began in 2012 with Norge Systems, developing ICE9, the first low-cost CO₂ SLS printer. Following Norge’s acquisition, the team spent six years at one of Europe’s leading 3D printing manufacturers, gaining deep expertise in R&D, market strategy, process development and application engineering.

In 2021, they founded Spengler to automate AM post-processing. The IntegrAM DCK 01 system, revolutionized SLS/MJF automatic depowdering and finishing, making it scalable and cost-efficient.

Building on this expertise, the Spengler founders also co-founded Verne AM, introducing the STROM SLS printer, designed to democratize high-temperature PEKK 3D printing. This step reinforced their commitment to pushing the boundaries of AM accessibility, efficiency, and automation.

VERNE AM

VERNE AM

52 rue Pierre Curie, 78370 Plaisir, France

Founded: 2024

www: verne.am

e-mail: contact@verne.am

social media: LinkedIn

Business activities: Hardware Manufacture and AM Service Provider

AM services:

SLS

Activity: Europe

Overview:

VERNE AM was born from the fusion of critical expertise in electronics, optics, and advanced system development, acquired by its founders over the past decade, with the goal of making SLS printing with high-performance PEKK materials accessible to everyone.

Thanks to its STROM powder-bed fusion 3D printer, Verne AM is democratizing the printing of high-performance polymers (PEEK, PEKK), designed to replace metal in critical applications where biocompatibility, thermal resistance, and chemical resistance are essential.

In addition to developing and commercializing printers for research centers and laboratories, Verne AM offers a specialized 3D printing service for manufacturing high-performance polymer (HPP) parts.

Legacy:

The VERNE AM team key contributions to the evolution of 3D printing include the Norge Systems ICE9, the first low-cost CO2 SLS printer, the Promaker P1000, the first industrial open SLS printer priced below €100K, and the IntegrAM DCK01 system, the first machine for automated de-caking, cleaning, finishing, powder recovery, and mixing of SLS cakes.