What can you do with 50 units of outdated 3D printers?

3DP War Journal #81

I don’t know if I’ve ever mentioned this, but Bambu Lab 3D printers - a company I’ve been working with for over half a year now - had earlier contributed to the collapse of one of my businesses…

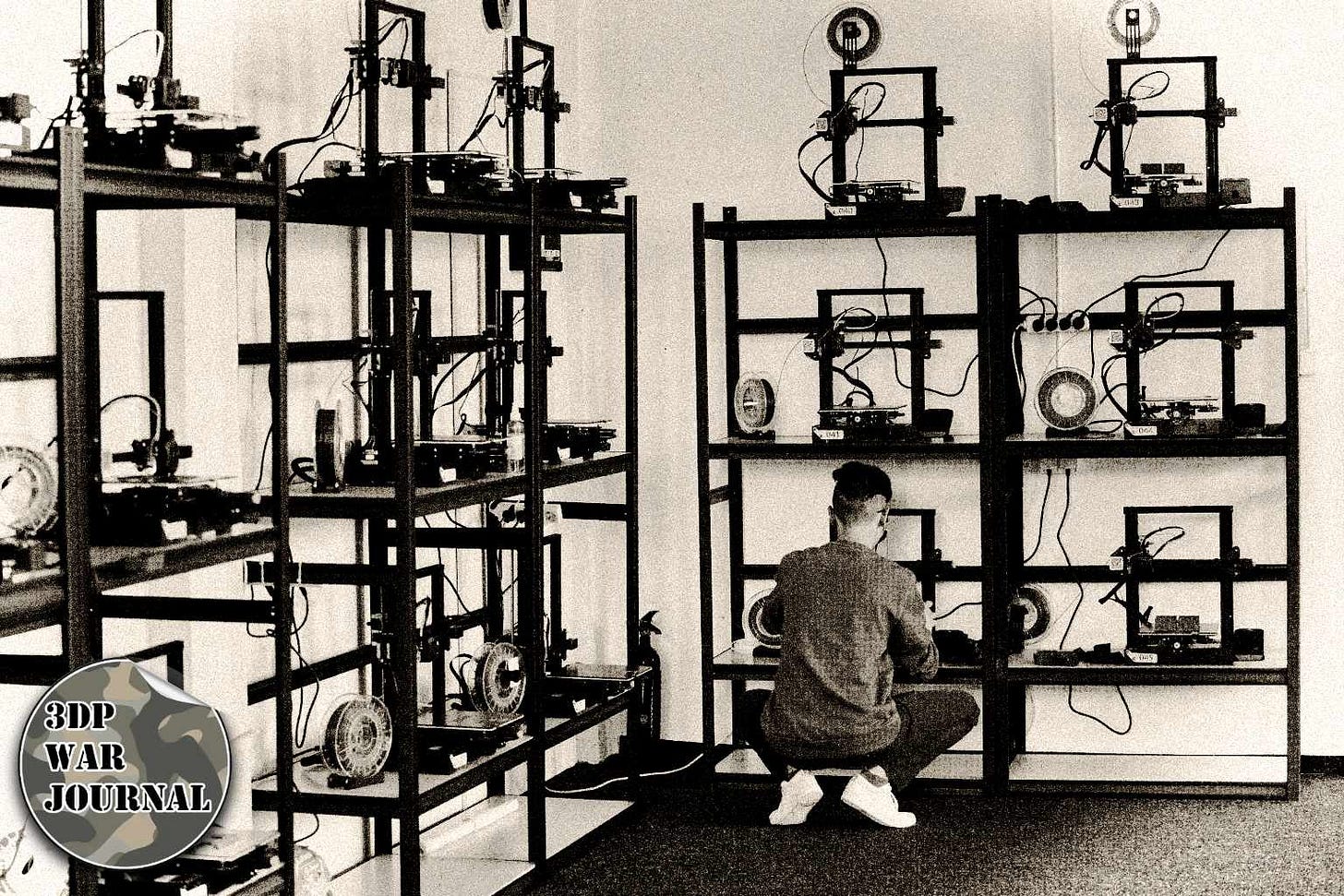

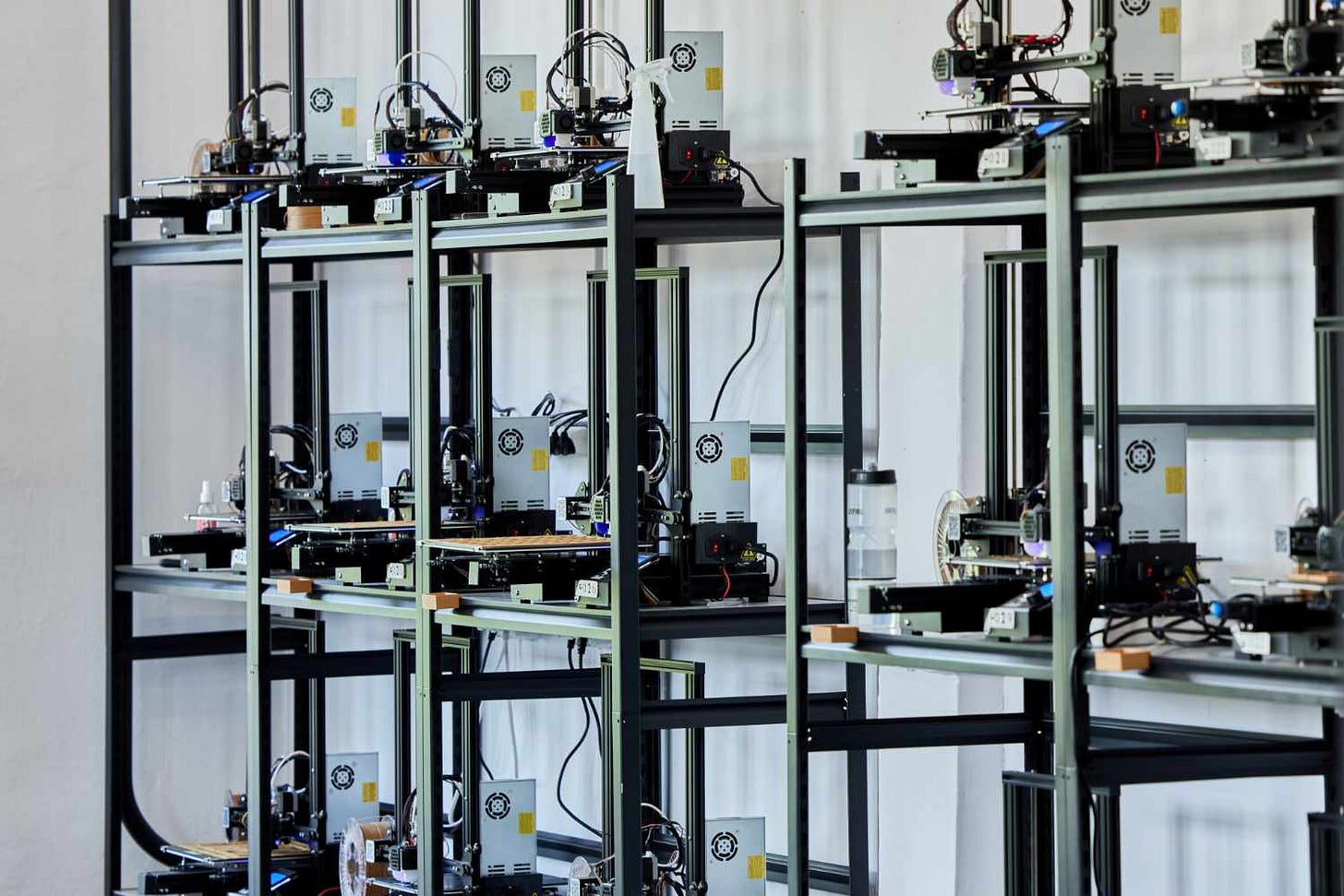

Of course, not directly - there were many more reasons. But yes: the mass expansion of the X1 Carbon, followed by the P1P and A1, made my proud fleet of over 50 Creality Ender 3 MAX and V2 machines practically useless...

Instead of ordering prints, companies gradually started buying their own 3D printers and producing parts in-house. The economics of those decisions were merciless for us... In the end, outsourcing those 3D prints to us simply stopped making sense - it just wasn’t profitable. For them, and for us as well…

But before we go any further, a few important words of clarification:

Our original business model behind the decision to purchase all those 3D printers was not traditional 3D printing services; the Ender 3 MAX and Ender 3 V2 were printing innovative advertising stands made from our proprietary biodegradable material based on wheat bran; I described this here:

Unfortunately, that business model collapsed because the limitations of 3D printing at the time (this was 2021-2023); technology did not allow for fast, efficient - and large-format - production of this type of advertising application; we could produce 100-120 such stands per month; clients expected 1,000-1,200... In fact, even today this is still barely realistic…

Then we switched to producing our own original products based on biodegradable eco-materials, but that also turned out to be a failure; customers had expectations that were impossible to meet; I described this here:

And yes, eventually we returned to what we never wanted to do in the first place - producing ordinary parts from ordinary materials - PLA, ASA, or PETG - for industrial clients.

But soon even that stopped making sense - both for the clients and for us - when it turned out that the Bambu Lab X1 Carbon and P1P (and the A1 and A1 Mini introduced at the beginning of 2024) completely outclassed our Enders, rendering them obsolete. As if they came from a different era…

It got to the point where, after buying just three P1Ps, we were fulfilling most orders on them.

Struggling with unreliable and painfully slow Ender 3s no longer made sense. Even the Prusa i3 and Prusa Mini machines we were using began to gather dust…

And we also had over a dozen Zortrax machines (M200, M300 DUAL, Inventure), plus several Wanhao, XYZPrinting units, and other more niche brands. All of it suddenly became old. Downright primitive.

And so - month after month, quarter after quarter - customers naturally started disappearing... No one said it out loud, no one bragged about it to us, but we knew that most of them had simply started deploying easy-to-use and highly reliable printers themselves.

Economics, man, economics... 5 P1Ps > 25 Ender 3 MAX machines...

This story isn’t new at all

What I’m describing has happened many times in the past...

At the beginning of the 20th century, the world entered one of the most violent technological transformations in the history of modern civilization.

People switched from horses to cars.

The automotive revolution, initiated by Henry Ford’s mass production of passenger cars, was not merely a change in means of transportation - it was a transformation of the entire economic system.

A system that for centuries had been built around horses as the fundamental element of communication and logistics.

Before the widespread adoption of automobiles, nearly entire cities functioned around horse-based transport.

Stables were an integral part of urban infrastructure, blacksmiths were among the key professions, and manufacturers of carriages, saddles, reins, and harnesses formed a powerful industrial sector. A massive market for horse feed, barn construction, storage facilities, and logistical back-end infrastructure drove agriculture and heavy industry.

Yes - although it may seem surreal today - just 100 years ago the horse was not only a means of transportation, but also the foundation of the global economy.

With the emergence of cheap, reliable, and mass-available automobiles, this world began to disappear at a pace no one had experienced before.

Within just a dozen or so years (in some cities even faster), horse-drawn transport was almost completely displaced. Companies that had recently been essential to the functioning of society became unnecessary.

The entire horse-based market shrank into a recreational, sporting, and hobbyist niche. The horse ceased to be an economic tool and became a symbol of tradition, luxury, or passion.

This story was one of the first of many similar phenomena that appeared with subsequent waves of innovation. At the end of the 20th century, a similar fate befell fax machines, which for years had been a fundamental tool of business communication until they were almost completely replaced by the internet and email.

At the same time, pagers - indispensable in the work of doctors and technical services - disappeared along with the popularization of mobile phones.

Analogous processes can be observed in other areas as well:

Film cameras and the entire industry associated with film production and photo development were reduced to a niche after the spread of digital photography.

Music carriers such as reel-to-reel tapes, cassette tapes, and CDs were pushed to the margins by streaming and digital distribution.

Video and DVD rental stores, which were still a common element of the urban landscape in the 1990s - and working in one of them was one of the coolest jobs a young person could have - have practically disappeared.

Each of these cases shows the same mechanism: technology does not destroy the old market gradually and gently; it often does so quickly, ruthlessly, and on a massive scale.

Products and business models that seem durable and irreplaceable can lose their reason for existence in a very short time.

In the world of technology, there is no such thing as a “safe” product or a secure business.

Old 3D printing

Today, CoreXY-based 3D printers are dominant. A 3D printing speed of 35 mm/s - an absolute standard up to 2023 - is no longer used even for printing the first layer…

What’s more, with the popularization of the 3MF format, which contains the complete set of information required for 3D printing (part orientation on the build plate, supports, distribution across build plates when needed, colors, filaments), most of the advantages once offered by a “3D printer operator” have lost their relevance.

Finally, after all these years, the STL format has become just as obsolete as PostScript once was in text printing.

And I’m left with a rather peculiar problem…

For over two years now, I’ve been doing something completely different with my life, but several dozen - still fully functional - 3D printers are sitting in my home warehouse. Yes, I slept through the moment when selling them would still have had value.

But today? Hobbyists who build their own 3D printers are an endangered species:

Converting them to FGF makes a little sense, as it’s still a very niche specialization. Besides, 3D printing from pellets only makes sense at large formats - not 20–30 cm on the axes…

So what should I do with them today…?

Any ideas?