Why do the Chinese copy Western software when they had far superior patterns at home?

The Atomic Layers: S6E30 (00177)

Atomic Layer of the Day:

Ok. This will be a longer post. But I assure you—it’s a very interesting one and quite thought-provoking…

Two days ago, I mentioned in News & Gossip that a small drama had erupted once again within the desktop FFF 3D printing community. This time, it started when Canadian user PhiltyPhil posted on X that Creality claimed in the description of its software—Creality Print—that it was "self-developed." However, according to Phil (and a number of other users, including Josef Průša himself), it is clearly a copy of the open-source OrcaSlicer.

As usual, this sparked a big debate about who copied whom and to what extent. Eventually, another well-known content creator, Joel Telling (3D Printing Nerd), posted a picture of the preloader from Flsun Slicer, where its Chinese developers openly credited the origins of the software.

The list of contributors was so long that instead of rewriting it, I’ll just share Telling’s picture here:

It’s honestly hilarious—this long train of companies copying each other, each independently emphasizing how unique their software is. But that’s not what I want to talk about…

As I was looking at all this, something completely different came to mind—old software from three different Chinese companies that looked nothing like anything created in the Western world!

These programs were:

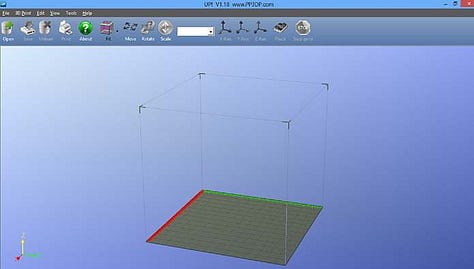

Up! by PP3DP (which was actually Tiertime)

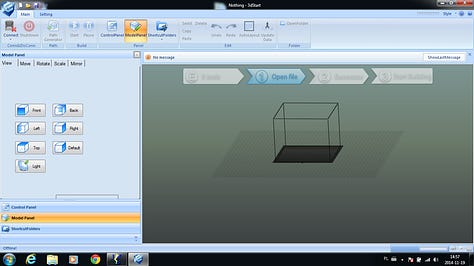

3D Start by Shining3D (a respected 3D scanners manufacturer)

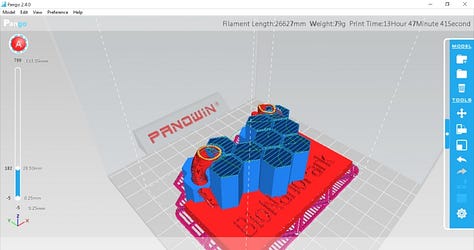

Pango by Panowin.

And here’s something important—each of these was developed in China before 2013. That’s a crucial detail we’ll come back to later.

What made this software unique?

Let’s start with the fact that Up! 3D printers from Tiertime/PP3DP were years ahead of their Western counterparts. When MakerBot introduced the first Replicator in January 2012—still with a wooden frame—Up! was already made entirely of metal components, featured automatic bed leveling, and had a removable perforated print platform.

Guys, automatic bed leveling didn’t appear in Western desktop 3D printers until about three years later!

The Up! software was incredibly simple—it had a handful of basic settings, which were more than enough to operate the printer efficiently. It generated high-quality toolpaths, resulting in excellent 3D prints.

Do you know who was the first Western company to take the same approach and develop equally good software? Zortrax, in 2014.

That’s the same Zortrax that, along with Up!, was the only other company to use perforated print beds. (Yes, this is a very deep rabbit hole—maybe someday, I’ll guide you all through it.)

3D Start by Shining 3D was used in the Einstar-S 3D printer. I worked with it in 2014, but both the printer and the software were older.

Visually, 3D Start looked excellent—setting an unmatched standard for CURA, Slic3r, and KISSlicer, the leading Western slicers at the time. Functionally, it was a bit clunky, and its algorithms weren’t top-tier, but overall, I have very good memories of working with it.

Now, let’s move on to Panowin - one of the most mysterious companies in the Chinese desktop 3D printing sector. But first, a bit of background…

In 2015, a company called Kodama Inc. launched a Kickstarter campaign for an innovative 3D printer called Trinus. It was relatively small but entirely made of metal, using solid, durable components. Additionally, despite being a DIY kit, it consisted of just a few pre-assembled parts—an unheard-of feature at the time. Assembly took a maximum of 20-30 minutes, whereas other kits required 2-3 days to put together.

Kodama raised $1.6 million and successfully fulfilled all orders. Later, they launched a second campaign for a more advanced model, Obsidian, but that ended in disaster…

Now, back to Trinus.

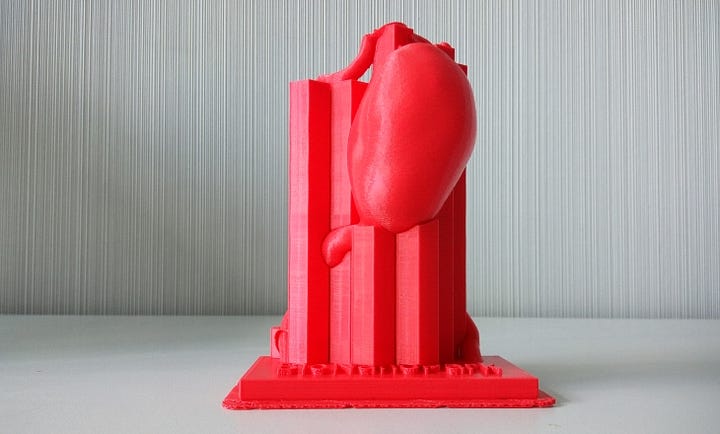

In 2016, I was contacted by a Chinese company called Panowin Technologies Co., Ltd. They asked if I’d be interested in reviewing their 3D printer on my former portal, Centrum Druku 3D.

To my surprise, the printer they wanted to send me was… Trinus.

When I asked about it, they brushed it off, saying that Kodama was merely a reseller, selling their printers in the West. I took their explanation at face value and agreed to review it. The printer arrived about two weeks later…

And it was amazing! At least for that time.

It was a bit noisy, but overall, fantastic. Oh, and it came with a swappable laser head, meaning it could also be used as a laser engraver!

I assembled my Panowin in the promised 20 minutes and launched the software—Pango.

Again, this was something completely different from anything I had seen before.

But the interface wasn’t even the most important part. What really mattered were the supports and raft.

Guys, the logic behind it was entirely different… Supports were built as independent column-like structures on separate hexagonal bases forming the raft. It was genius.

For the first time, I could print models that had previously been impossible to produce with FDM.

And now, the craziest part!

While digging through the documents on the USB drive that came with the printer, I found information stating that both the printer and the software were developed in 2012—or earlier!

How on earth did Chinese companies have such advanced software at a time when Western 3D printers were still built from wooden frames and relied on primitive, clunky slicers like Repetier Host, early CURA, or Slic3r?

My theory?

They simply started working on it many years earlier—before they were even officially allowed to. You know… patents.

But hey, that’s just my theory. Don’t take it too seriously. I’m sure the real story is completely different—I just don’t know what it is.

So, back to the big question:

Why did Creality, Elegoo, Bambu Lab, and earlier companies like Tronxy, Anet, and Tevo copy Western software, when much more advanced programs had already been developed locally?

I honestly don’t have an answer…

Because they didn’t know about it? That makes no sense.

Because the local software was closed-source while Western slicers were open-source?

Because the Chinese software was restricted by copyright laws?

I have no idea… But if you’d like to learn more about any of the slicers I mentioned—just let me know. Pango runs as a standalone program without requiring installation. I might still have it somewhere (if I dig around).

Atomic Layer from the Past:

01-30-2018: EOS opened a new 3D printer factory in Maisach-Gerlinden.

News & Gossip:

Roland DG has introduced two ceramic binder jet 3D printers, the PB-600 and PB-400, designed for creative and educational applications. Using Brightorb artificial ceramic powder, they enable high precision with minimal shrinkage. Originally teased in 2016, the technology is now showcased at TCT Japan.

Dimanex has introduced a CO2e Reduction Indicator to quantify the environmental benefits of additive manufacturing. By reducing waste, scrapped parts, and long-distance transport, companies can lower emissions. One customer cut CO2e by 80 kg annually by sourcing locally. The tool helps businesses optimize sustainability and support ESG reporting.

And finally - people cry about Bambu Lab closed firmware issues. Meanwhile, Dubai-based UltraTec, has expanded its FDM farm with 50 high-performance Bambu Labs printers, increasing production capacity. UltraTec provides top-tier additive manufacturing solutions in the Middle East.

Regarding Roland’s new binder jet printers, what is “reasonable shrinkage? Theoretical packing density is ~65%