A secret oldtimers don't want to talk about: How early AM software slowed down an entire industry

The Atomic Layers: S9E27 (00264)

Atomic Layer of the Day:

As you all know very well, I specialize in searching, describing, and diagnosing the problems the AM industry is struggling with. There are tons of people out there who focus on the opposite—listing the advantages and strengths of 3D printing. But not me… I focus on the negatives. I look through grey glasses, not rose-colored ones.

Heh, and that’s exactly why you subscribed to my newsletter and read what I have to say every day 😆

Tired of the success propaganda, you’re looking for a sober and honest perspective on the industry. No sugarcoating, no BS. Straight edge to the core.

Alright then, Pawel, so why don’t you tell us about the problems the AM industry is dealing with? What have you come up with this time?

My friends, I’m glad you asked! One of the many issues is software. More specifically—its historical mismatch with user needs.

To put it briefly: for years, the driving force behind the industry was hardware, while software was always treated as an afterthought. Software was just an accessory to the hardware—not the other way around.

Historically, every press release showcasing a new 3D printer focused on its technical specs (build volume, accuracy, number of print heads/lasers, material processing temperatures, etc.), and rarely mentioned the software, which was treated on par with the power cable. It had to be there for the 3D printer to work—but that was it.

When I started my career in the industry back in 2013, every desktop 3D printer used one of three free, open-source programs: Slic3r, Cura, or KISSlicer. They differed in visual design and interface, but functionally they all worked the same way.

No one really questioned it back then—everyone was just happy that something existed at all. The programs were deeply imperfect, but there was no alternative.

As I began to explore the topic more deeply, I started uncovering the background behind the development of each of these programs. Do you even know where these slicers originally came from?

The first slicer for desktop-grade FFF 3D printers was RepRap Host, written in Java by RepRap project creator Adrian Bowyer. It was very primitive and simple, but true to the RepRap project's philosophy, it was meant to be just a base for the community to build on.

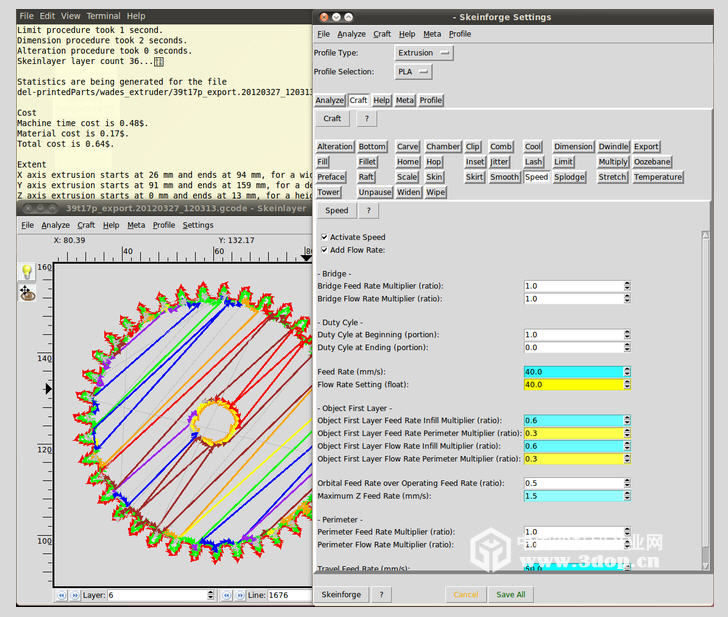

Next came Skeinforge, created by Brazilian developer Enrique Perez. Most of the subsequent slicers (Slic3r, Cura, KISSlicer) were based on Skeinforge’s architecture. From the beginning, G-code generated by the slicer was interpreted using Pronterface.

Here's a fun fact: Perez wrote the code without access to a 3D printer. That’s right—Skeinforge, the mother of all FFF slicers, was created by someone who didn’t even use 3D printing.

Skeinforge was very complicated to use and required actual knowledge of 3D printing to operate. On top of that, it wasn’t GUI-based—it was controlled via command line, with specific commands you had to know.

In parallel, the MakerBot team developed ReplicatorG, which was based on Bowyer’s original RepRap Host and was also quite complex to use.

In 2011, work began on the first alternative slicers that addressed the needs of new, beginner users. David Braam started developing Cura, and Alessandro Ranellucci began creating Slic3r. The former became the official software for Ultimaker (and was also used by countless other companies, including Creality), while the latter became the foundation for PrusaSlicer and Bambu Studio.

Each of these programs already offered a graphical user interface and, compared to their predecessors, were easier and more intuitive to use. However, they still required the user to have a solid understanding of what 3D printing was and how a 3D printer actually worked. Slicers at that time allowed users to prepare models for 3D printing, but when it came to configuring individual settings, users were entirely on their own.

This is largely why the consumer 3D printing revolution—and the promise of a 3D printer in every home—never really materialized.

Mid-2010s 3D printers may have been reasonably functional, aesthetically pleasing, and relatively easy to use, but in terms of software, they still demanded a lot of knowledge—and most importantly, experience. Every beginner made the same set of common mistakes (such as incorrectly orienting the model on the build plate), and the results were either failed prints or print quality that fell far short of expectations.

It wasn’t until 10 years later, around 2023–2024, that companies like Bambu Lab and Prusa Research simplified this process. With their respective software—Bambu Studio and PrusaSlicer—they made working with a 3D printer easier and far less dependent on deep knowledge or prior experience.

But this all applies to low-cost desktop 3D printers. In that segment, we can assume that for many, many years, software was treated as a secondary matter, because companies producing cheap 3D printers simply didn’t have the financial resources to invest heavily in software development.

What came as a major discovery for me early in my career (around 2014) was that the software used in large, expensive, industrial 3D printing systems was also far from perfect.

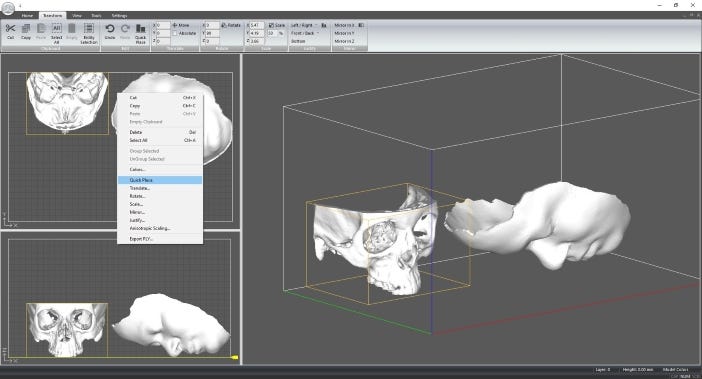

In those systems as well, users were left on their own when it came to job parameterization, defining print settings for materials, generating support structures, or even just orienting the model properly on the build plate—just like with desktop FFF printers.

I remember in 2017, when I first encountered gypsum powder 3D printing on the 3D Systems ProJet 660 Pro, I was really surprised by how raw and limited the software was. It looked like it had been taken straight out of the early 2000s!

I had the exact same impression a year later in 2018, when I briefly worked with the metal 3D Systems ProX DMP 320. Again, the software was a big disappointment. Considering how expensive the machine itself was, the fact that you had to manually configure such a large number of technical parameters felt completely unreasonable.

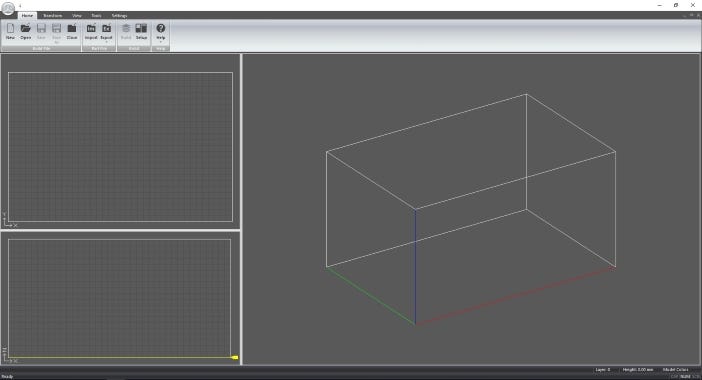

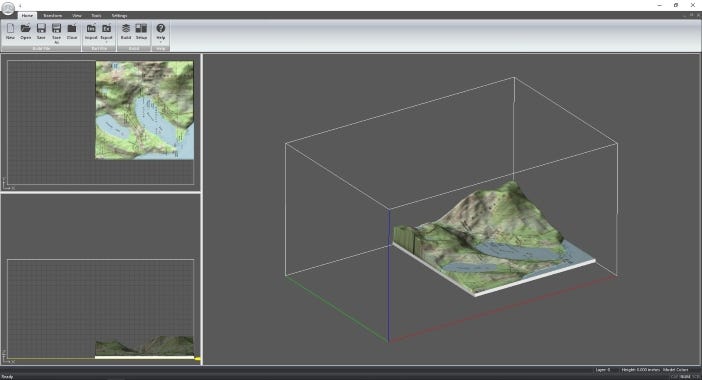

For many years, the standard software used in L-PBF 3D printers (polymer-based SLS and metal-based SLM or DMLS) was Materialise’s Magics . However, its primary role was nesting—arranging 3D models within the printer's build chamber—and setting global 3D printing parameters.

Just like with open-source FFF software, here too, everything was placed on the user’s shoulders.

The only difference was that the cost of mistakes was incomparably higher—sometimes amounting to the value of several 3D printers!

Here’s another anecdote: colleagues from e-Prototypy—the first Polish company offering 3D printing services, acquired by Materialise in 2014—told me that when they purchased their first SLS 3D printers from EOS in the late 2000s and early 2010s, it took them almost two years of trial and error before they finally mastered the machines enough to make the work predictable. It was a combination of 3D printing parameters set in the software and the environmental conditions of the production room (such as temperature and humidity).

No one wrote this down or defined it precisely. Every company had to figure it out for themselves back then.

Honestly, those old industrial-grade machines weren’t that different from the early RepRap-based FFF 3D printers. Except, of course, for the price, which was drastically different.

In fact, until 2019, the industrial AM sector operated under a status quo very similar to that of desktop 3D printing. Only with the introduction of Dyndrite that year did a real revolution in 3D printing software begin. The company introduced a completely new approach to processing geometric data and developing manufacturing tools.

Dyndrite’s founder, Harshil Goel, observed that hardware capabilities in 3D printing had far outpaced available software. Users struggled with all the aforementioned issues, which consumed time and limited efficiency.

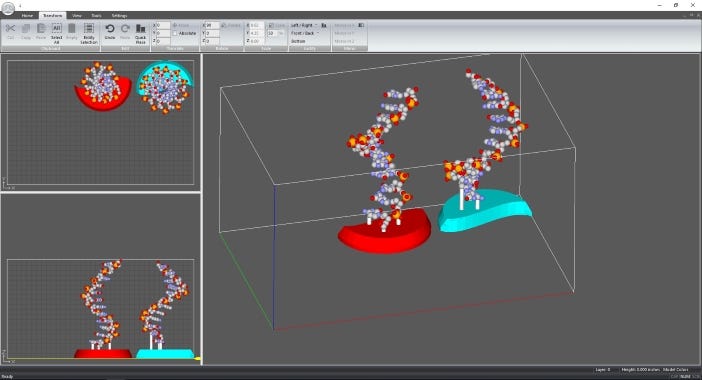

Dyndrite set out to change that. They first created their Accelerated Computation Engine (ACE)—a modern, GPU-based geometry engine capable of processing complex 3D models and native CAD data much faster than traditional solutions.

The company then developed an App Development Kit (ADK), allowing 3D printer manufacturers and software developers to build their own tools tailored to their specific needs. In November of 2020 they released their first end-user and flagship application, Dyndrite LPBF Pro, enabling advanced path planning and precise process parameter control for metal printing.

Thanks to its high computational power, new features are emerging, one example is 3D volume segmentation, which allows different parts of a model to be assigned different parameters making it possible to print parts with thin walls, small features, and low overhangs without the need for supports—resulting in higher quality prints, faster..

Another key aspect of Dyndrite is their use of Python.

Even if you’re not a programmer the importance of this capability cannot be over stated. Python is an easy to use, human readable language that’s pretty standard fare in most schools - it’s also the language of AI. Just about every aspect of Dyndrite has a Python API, it’s even built into the dialogs so you can modify the code directly.

Dyndrite’s deep Python integration means you can write very elaborate programs or “build recipes" that programmatically define parameters, integrate and generate production data, and define rules that drive automation - the holy grail of digital manufacturing.

This level of openness means you can innovate - create new tools based on new machines, materials, or process workflows, and eliminate tribal knowledge by sharing scripts.

Nearly every aspect of Dyndrite is exposed through a Python API—even the user dialogs allow direct code modification. This deep Python integration means you can create sophisticated programs or "build recipes" that can define parameters, generate production data, and automate processes—delivering on a promise of digital manufacturing.

It will enable users to innovate freely: developing new tools, techniques and workflows.

We could even see the elimination of tribal knowledge as users begin sharing standardized scripts across their teams and ultimately the industry.

It’s pretty clear Dyndrite isn’t just another slicer. They’re intent onchanging the way the AM industry thinks about software—from being a supporting tool to becoming an integral part of the manufacturing process. Let’s wish them well!

Atomic Layer from the Past:

04-27-2021: Stratasys introduced the H350, powered by SAF technology, and the large-format F770 FDM 3D printer.

News & Gossip:

RUMOR ALERT! Apparently, a well-known company from the Netherlands that produces large FFF 3D printers (no, not UltiMaker) has shut down. There’s no information about it on their website or LinkedIn profile. But people are saying it’s already over…

As we know, the status of Desktop Metal is highly uncertain. At the same time, similar reports are coming in from different parts of the world: selected distributors are still offering the company's 3D printers as if nothing had happened — as if everything were operating as usual. Maybe they’re living in denial, or maybe they’re just clearing out leftover stock? The same seems to be happening with some representatives of Nexa3D around the world, who also don't seem ready to acknowledge the news about their "scaled down operations."

South Korea’s DN Solutions has entered the metal AM market, unveiling its DLX series of laser powder bed fusion printers at DIMF 2025. The flagship DLX 450 prints aluminium, Inconel, and titanium with up to four lasers. DN Solutions also launched an AM Solution Center in Germany, expanding global support.

Once again, excellent recap Pawel. Thank you for the trip down memory lane.

On the software side, cura actually helped a lot of companies to make the production environment better, the markplace never worked as it shod but it was still a great gateway for developers create solutions s for 3D people ters, smartslicer the first free CAE software for FFF parts was first introduced there (I still have the email saying that I was the first to review it in whole world. Shame it never took ot full potential. On the rumors side please don't say another company has "drop" from the pantheon