AMIS Runtime promises to automate AM build preparation workflows

RECODE.AM #38

As I have repeated many times, for decades the industrial 3D printing industry has focused primarily on increasing machine productivity and adding or validating new materials, while the software layer remained largely in the background.

As a result, stages such as build preparation were often left to fend for themselves - meaning that users simply had to figure things out on their own.

This is precisely the area targeted by a new solution developed by the Belgian company AMIS.

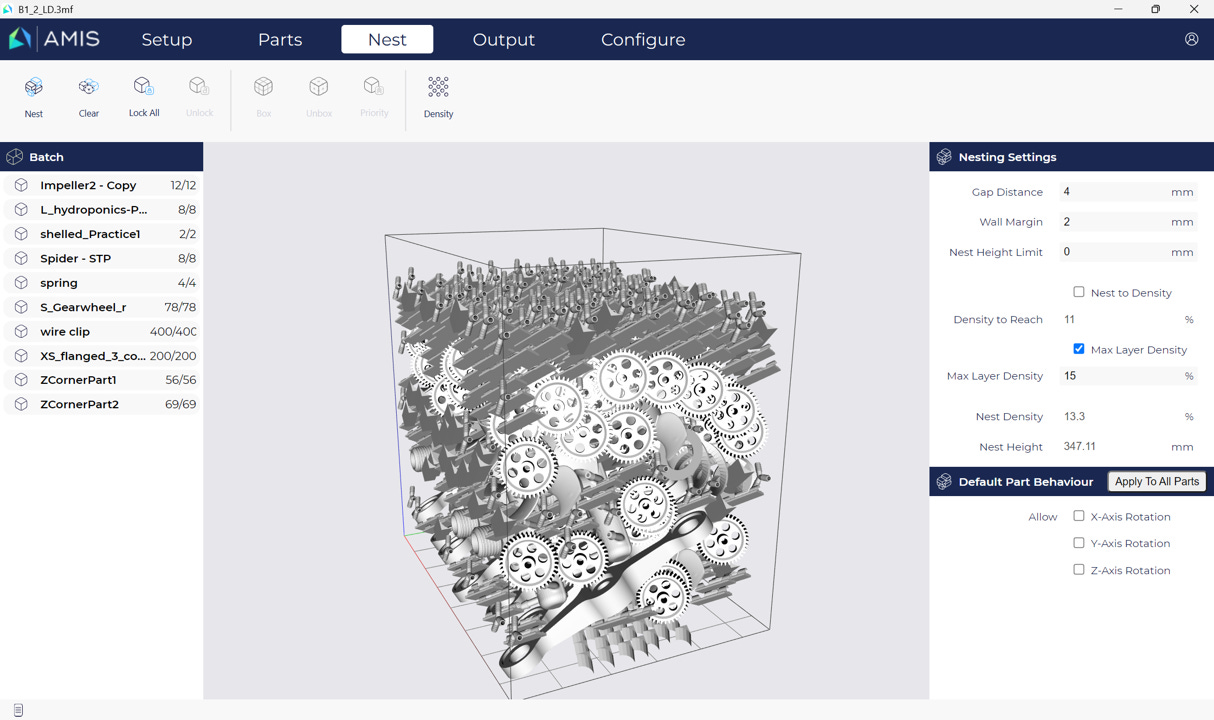

The firm has introduced the AMIS Runtime platform, an automation and scripting engine designed to reduce manual operations in preparing production jobs for powder-based additive manufacturing technologies.

The new software has been designed as an extension of the capabilities known from the AMIS Pro system, but its role goes beyond typical tools supporting nesting or slicing.

Runtime is intended to function as an automation layer, allowing users to define fully configurable and repeatable production preparation procedures - from model import all the way to exporting machine-ready files.

In practice, this represents an attempt to move additive manufacturing closer to an industrial production model, where processes are predictable, controlled, and scalable without a proportional increase in operator workload.

As I have described in numerous articles in this series, one of the key challenges in industrial 3D printing remains the fact that many operations are still performed manually or semi-automatically.

Model imports, metadata corrections, batch preparation, or manually arranging parts in the build chamber consume a significant amount of time and remain prone to human error.

AMIS Runtime aims to eliminate exactly this category of tasks. The system allows users to program nesting rules and production preparation logic based on part characteristics, geometry, size classes, or business tags.

As a result, different types of components can be automatically assigned to different optimisation strategies, enabling better use of machine build space and reducing preparation time.

An important aspect of the solution is also the concept of continuous re-nesting. Until a job physically starts printing, the system can automatically rebuild the layout of parts, taking into account new models, shifting priorities, or schedule adjustments.

In practice, this means treating parts as a virtual inventory from which the system independently creates optimal production batches.

The developer emphasises that Runtime is not limited to isolated automation features, but instead provides full programmable access to the build preparation process.

The platform is built around an API that enables control over operations on batches, parts, and nesting or slicing parameters. This allows production preparation to be described as a set of scripts that execute identically every time they are run.

AMIS also claims the ability to support fully autonomous, continuous preparation of production batches. The company presents it as the first AM solution capable of completely automated and dynamically rebuilt part layouts without operator involvement.

If these claims hold up in practice, it could signal a shift toward more autonomous production environments, where job preparation runs in the background, parallel to machine operation.

From a manufacturing economics perspective, such a change could have meaningful consequences. Denser packing of parts, fewer rebuilds, and more predictable workflows translate directly into lower cost per component.

At the same time, automation enables companies to handle larger job volumes without proportionally increasing headcount - a factor that can be critical in facilities experiencing growing production demand.

This does not mean, however, that the solution is without potential limitations. Automating build preparation always requires trust in algorithms and a precise definition of the rules according to which the system makes decisions.

In practice, implementing such an approach may require an initial investment of effort to configure processes and integrate with MES, ERP, or reporting tools. Only after this stage can the full benefits of automation be realised.

From the perspective of the AM software market, the launch of Runtime fits into a broader trend of shifting focus from the printing process itself toward production management. Increasingly, it is data flow, automated decision-making, and system integration that determine the competitive advantage of companies using additive technologies.

Ultimately, AMIS Runtime attempts to bring order to a stage that has long represented a bottleneck in many industrial implementations. If the system truly delivers operational stability and predictable workflows across diverse production environments, it may become an important component of the digital infrastructure supporting industrial 3D printing.