How Bambu Lab made 3MF the standard in desktop FFF without giving much in return

The Atomic Layers: S8E2 (00208)

Atomic Layer of the Day:

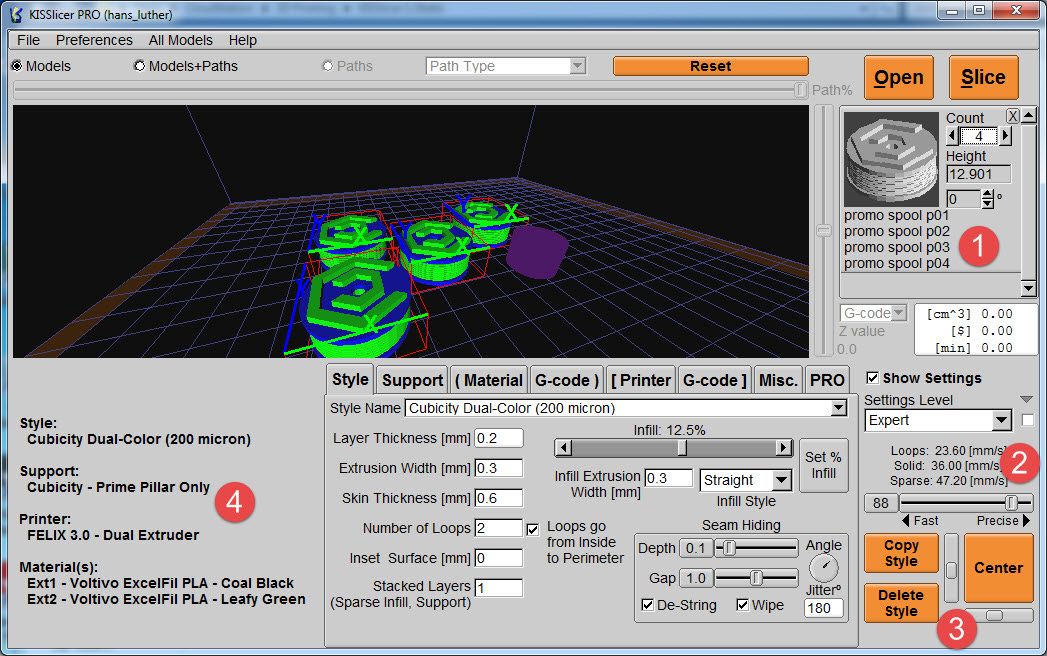

Back in the day, my wife Anna used to use 3D printers quite a lot—mostly an old-school Polish Prusa i3 clone, the Monkeyfab Prime. The software she was using was just as old-school: KISSlicer (hands up if you used it and still remember it!).

Then, after the pandemic, her interest faded. Even though we had more 3D printers than ever (~70), someone else was always handling the printing, while Anna just assigned the jobs.

But last year, there was an urgent need for something, and we sat down together to work with a slicer again. This time, though, it wasn’t the archaic KISSlicer or even CURA—it was the latest version of Bambu Studio.

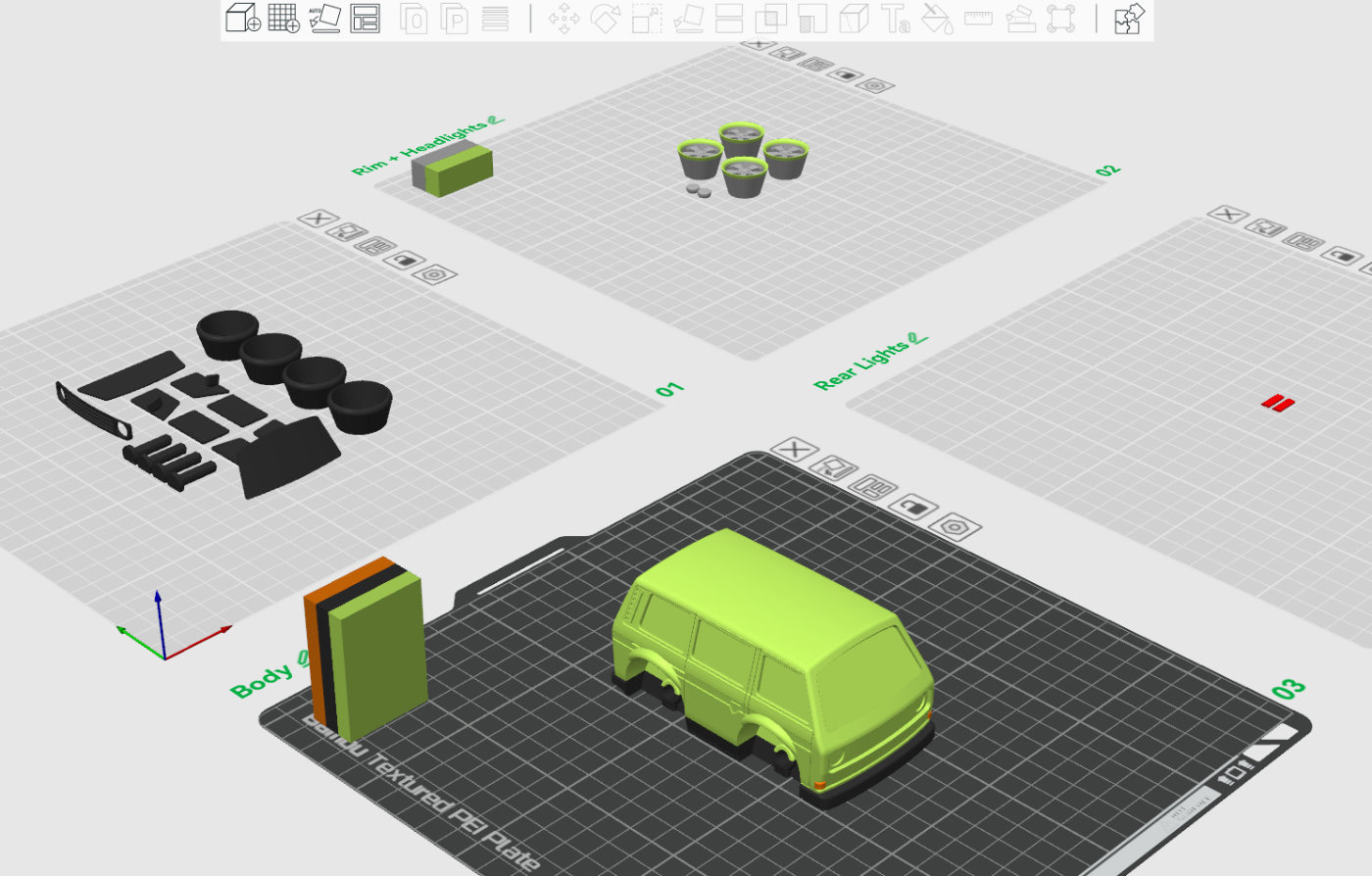

For the first time, Anna saw full-color .3MF files in action, and it was a huge surprise for her—a true technological leap. You see, the last time she worked with a slicer, things like generating support structures, orienting 3D prints on the build plate, or arranging assembly prints were all standard manual tasks.

Today, all of that is stored in a single 3MF file.

Those who print regularly know this. Those who are just starting out assume it’s always been this way.

But here are two facts:

The 3MF format has been around for a good decade.

It’s only really become widespread in the last two years.

Bambu Lab popularized it with Bambu Studio. But, as is often the case, they built on existing work… while those who put in the real effort were left behind.

Let’s start the story from the beginning…

The .3MF format (3D Manufacturing Format) is an open-source file format designed specifically for AM. It was developed by the 3MF Consortium, which was created by software giants in form of Microsoft, Autodesk and HP. Others soon joined, including Siemens and Dassault Systèmes, as well as top AM companies like 3D Systems, Stratasys, SLM Solutions or EOS.

The goal was to address the limitations of legacy formats like STL and OBJ.

The .3MF format aimed to support advanced features such as multi-color and multi-material data, textures, metadata, and precise geometry, making it more suitable for modern 3D printing workflows.

For years 3MF format was a thing widely discussed but little used. Despite lot of contribution from Ultimaker and Prusa Research, in the sphere of desktop FFF 3D printing, the STL file ruled uninterrupted.

Then in 2022, Bambu Lab, has integrated the 3MF format into its ecosystem. Bambu Lab has leveraged the capabilities of .3MF to enhance the user experience and streamline the 3D printing process.

Bambu Lab’s printers, such as the X1 series, support multi-material and multi-color printing. The 3MF format’s ability to store information about multiple materials and colors in a single file aligns perfectly with Bambu Lab’s hardware capabilities.

Bambu Studio uses 3MF as its native file format, enabling seamless integration of design, slicing, and printing. This eliminates the need for file conversions and ensures that all relevant data (e.g., supports, settings, and metadata) are preserved in a single file.

The 3MF format allows for the inclusion of metadata, such as printer settings, material information, and slicing parameters. Bambu Studio utilizes this feature to store and retrieve print settings, making it easier for users to share and reproduce prints accurately.

Given the gigantic popularity of Bambu Lab printers, the 3MF usage spread like wildfire!

However, we need to be aware, that while Bambu Lab has effectively utilized the 3MF format, the company did not develop the format itself.

Bambu Lab’s contributions are primarily in the application and optimization of the format for their specific hardware and software.

The company’s role is more about adoption and optimization rather than innovation or development of the format itself.

Bambu Lab took an existing solution, adapted it, and now everyone is using it. Kind of like how with FFF 3D printing in the first place. Or firmware.

So yeah...

Atomic Layer from the Past:

03-02-2022: BCN3D introduced a new resin-based 3D printing technology.

Join AM World Map and fill your country or region with Additive Manufacturing!

News & Gossip:

Creaform has launched Scan-to-CAD Pro, an advanced module in the Creaform Metrology Suite, enhancing reverse engineering workflows. With 2D sketching and 3D modeling tools, it simplifies scan-to-CAD conversion, reducing reliance on external software.

Bright Laser Technology has overtaken Farsoon as the most valuable publicly traded Chinese 3D printing company. Farsoon’s stock dropped 4% after last week’s surge, likely due to profit-taking, while Bright Laser gained 10%. Market valuation of both of them exceeded two billion dollars ($2,432 of BLT and $2,312 of Farsoon).

On American stock market Xometry’s stock fell 15% despite reporting 20% revenue growth, despite record revenues. Meanwhile, 3D Systems dropped 17% ahead of its financial report, with no major news explaining the decline.