Reinforced from the inside - explaining the continuous fiber injection technology

3DP War Journal #79

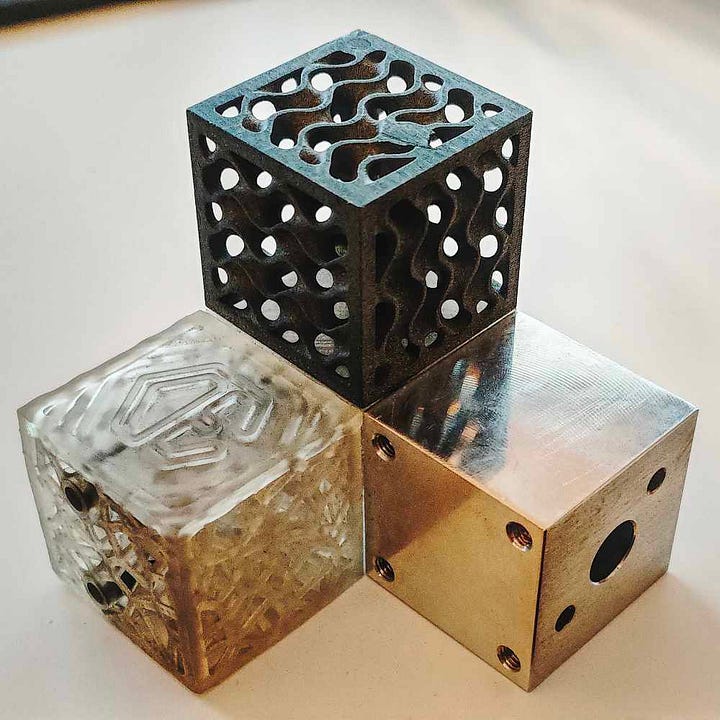

For years, 3D printing has struggled with one fundamental limitation: strength. Layer-by-layer fabrication simply couldn’t match the performance of molded or machined parts. Reinforce3D takes a radically different approach - printing parts first, then reinforcing them from the inside using continuous fiber injection.

This limitation has positioned additive manufacturing behind traditional production methods such as injection molding, casting, and CNC machining - technologies that benefit from material homogeneity and isotropic mechanical properties, something layer-based fabrication has historically been unable to deliver.

By default, 3D printing was at a disadvantage, because building objects layer by layer could not provide the same homogeneity as cast parts or components machined from a solid block of material.

The strength of a part was only as good as the bonding between layers…

Nevertheless, attempts were made to address this through the introduction of increasingly strong materials and process optimization.

In 2014, the American startup Markforged introduced the first desktop 3D printer that combined polymer 3D printing (polyamide) with continuous fiber - carbon, glass, or Kevlar.

At the time, this was a true revolution that initiated a trend toward working with high-performance and composite materials reinforced with fibers in various forms.

But ultimately, the core problem remained the same - regardless of the material used and the way it was bonded, everything came down to interlayer strength.

Meanwhile, a Spanish company decided to approach the problem in a completely different way…

What if a part were first printed from a given material and then reinforced… from the inside?

Reinforce3D

I first encountered Reinforce3D in January 2025 while preparing the Spanish edition of The 3D Printing World Guide. Initially, it was simply one of several companies that reached out to us, and apart from preparing its company profile for the catalog, it did not particularly catch my attention.

I also didn’t fully understand its technology and offering at the time… CFIP (Continuous Fiber Injection Process) was, back then, just another sophisticated acronym that didn’t mean much to me. Another “innovative technology changing the face of AM” for the collection…

However, shortly after publication, Bartu Mompeán - the company’s sales manager, with long and extensive experience not only in additive manufacturing - contacted me. Bartu had worked for many years at HP and later at BCN3D. I thought it would be a great opportunity to meet and exchange insights.

But surprisingly for me, the news and industry gossip turned out to be merely an addition to truly understanding Reinforce3D’s concept, and what the method of injecting continuous fibers really is.

During the meeting, I also met Blanca Garro - the company’s CEO, who had previously worked, among others, at Materialise.

Together, they briefly told me the company’s story, explained how the technology works, and showed me several parts…

Later, Bartu sent me one of the demo components and… that finally sold me on CFIP. I instantly became a huge fan of this solution!

In theory, Reinforce3D and I were supposed to establish some form of collaboration, but it never materialized. Instead, I quite often met Bartu for informal conversations about the AM industry, and we simply became friends.

After meeting both Blanca & Bartu at Formnext, and seeing their latest achievement, I decided to present this unusual solution to you in more detail.

What is Continuous Fiber Injection Process and where did it come from?

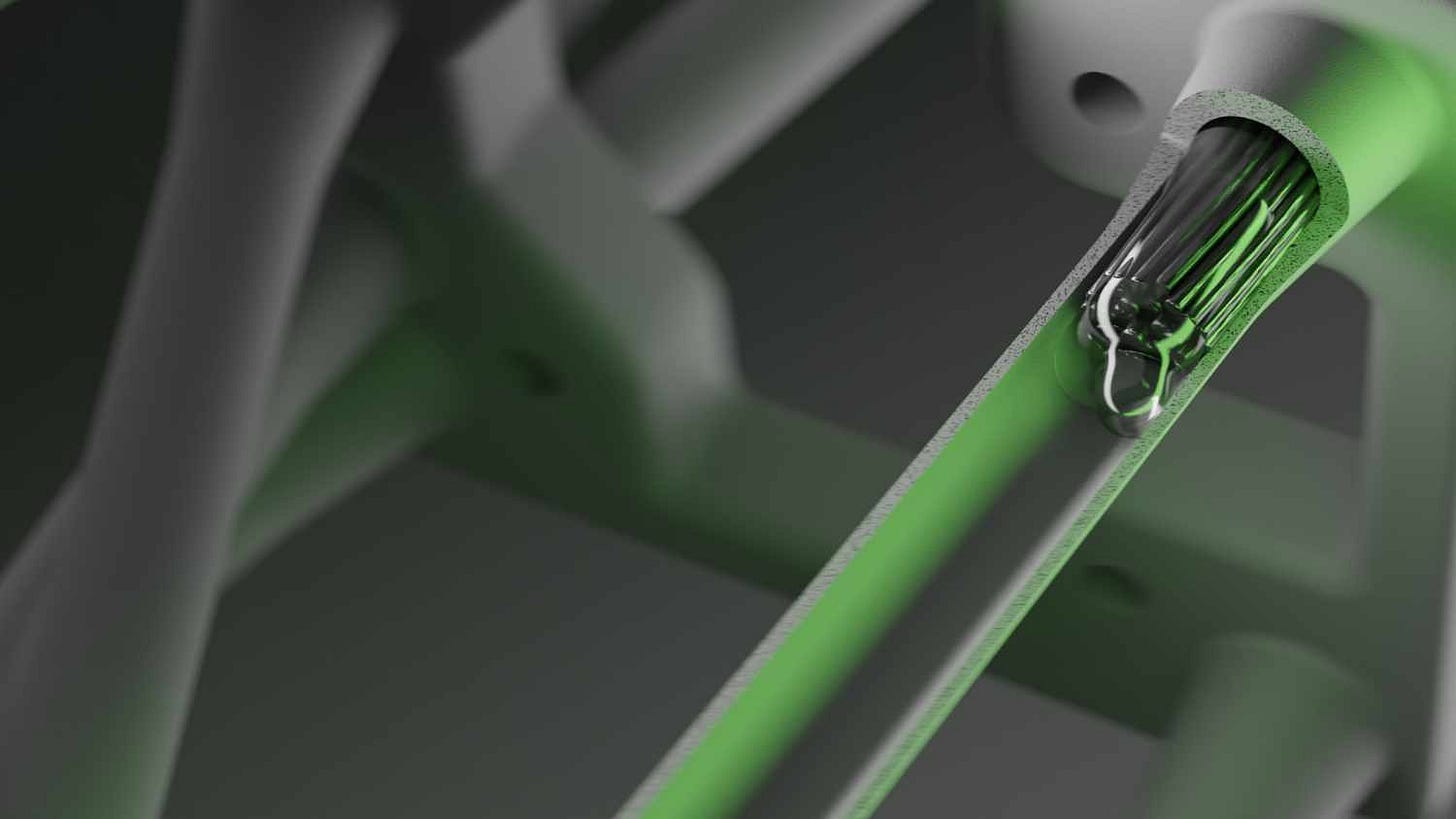

The idea behind CFIP stems from the technical observation mentioned at the beginning: 3D printing offers great design freedom and cost optimization, but in return provides limited structural strength due to weak bonding between printed layers.

Marc Crescenti, co-founder of Reinforce3D and it’s CTO, began researching this problem as early as 2011. He started using 3D printers and quickly realized that conventional AM could not provide the mechanical strength required for functional parts.

He ultimately concluded that attempting to reinforce parts during the printing process itself would not solve the issue of weak interlayer bonding.

Instead, he began working on the concept of reinforcing parts - but after printing.

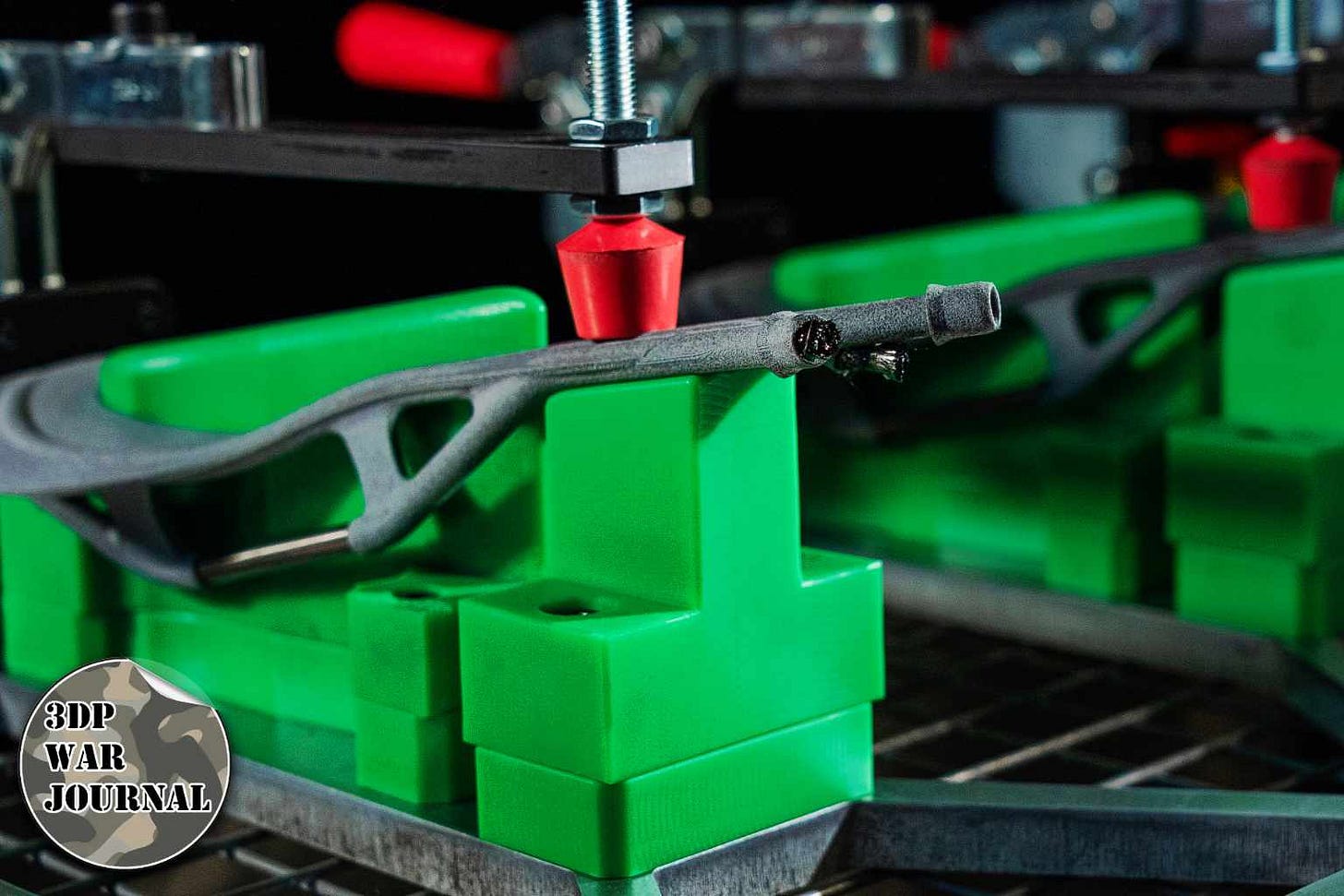

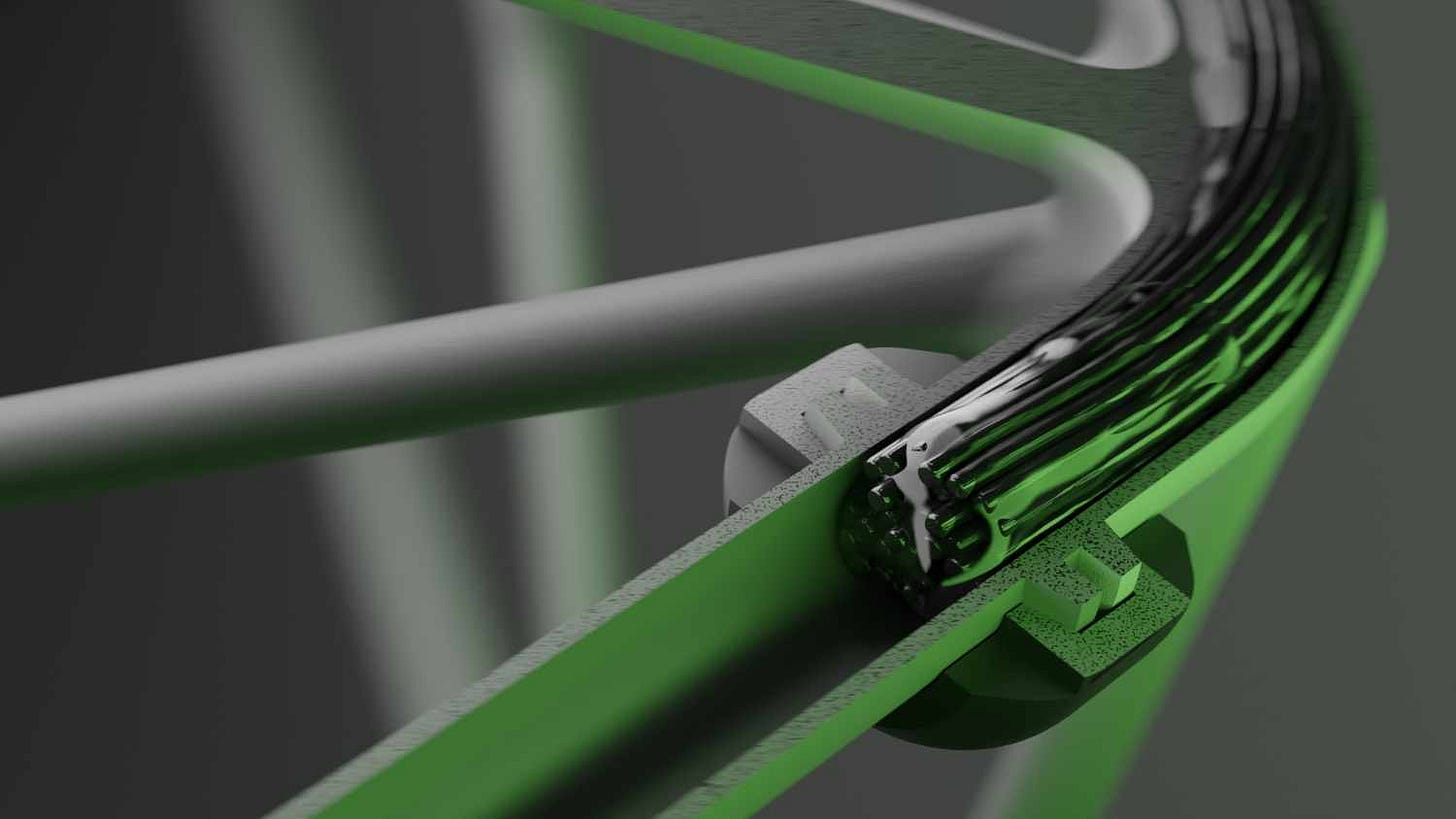

This led to the birth of CFIP - the injection of continuous fibers into internal channels of printed or cast parts, after the initial structure has been created.

Marc carried out the first experimental validations in 2013, using self-built equipment in his kitchen, successfully demonstrating the basic principle of the technology.

In 2014, he joined the CETECOM technology center (now Eurecat), and shortly thereafter the first patent for CFIP technology was filed. Years of laboratory-scale validation followed, eventually leading to an industrial version of the technology.

However, patents alone do not build companies. What changed everything was the involvement of BeAble Capital, a VC fund specializing in deep-tech solutions for industry. When BeAble discovered CFIP, it recognized not only its technical potential but also the market gap it could fill, and decided to provide the resources and support needed to turn the technology into a company. This is how Reinforce3D was founded in 2022.

Blanca Garro took on the role of CEO, having previously spent nearly four years at Materialise as a Project Manager, coordinating production for sectors such as automotive, aerospace, and ophthalmics.

The core team also includes:

Marc Roselló - Operations Manager, who played a key role in transforming CFIP from a functional prototype into an industrial process; today he oversees both Production and Customer Support.

Bartu Mompeán - Sales Manager and AM industry veteran, with experience at companies such as HP, BCN3D, and Siconova.

What is it used for?

CFIP is ideally suited for high-value sectors, including sports, UAVs, medical devices, defense, and automotive - anywhere that the combination of lightweight performance and production flexibility is highly sought after.

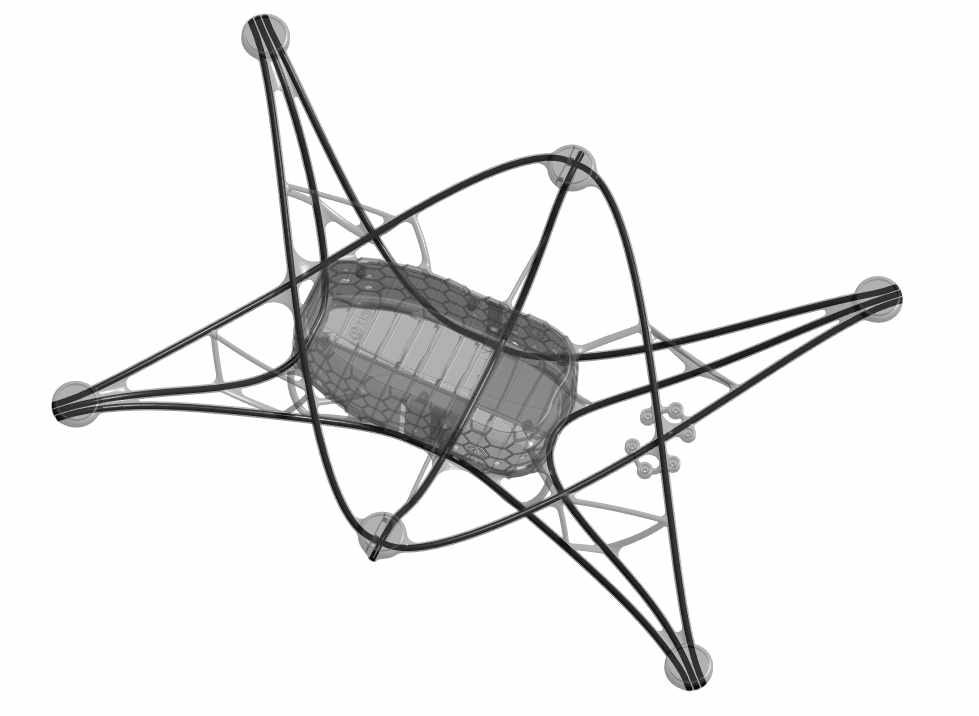

In 2023, the company introduced its first CFIP-based machine - the Delta system. This marked the first time continuous fiber injection was presented as a standalone reinforcement method, enabling internal reinforcement without molds, adhesives, or co-printing.

Additionally, CFIP enables permanent joining of components without additional bonding, which is particularly useful, for example, when joining plastics to metal or polymers with different specific properties (e.g., photopolymer resin parts with ABS or PA).

Reinforce3D systems began to be used by leading companies in the aforementioned manufacturing sectors.

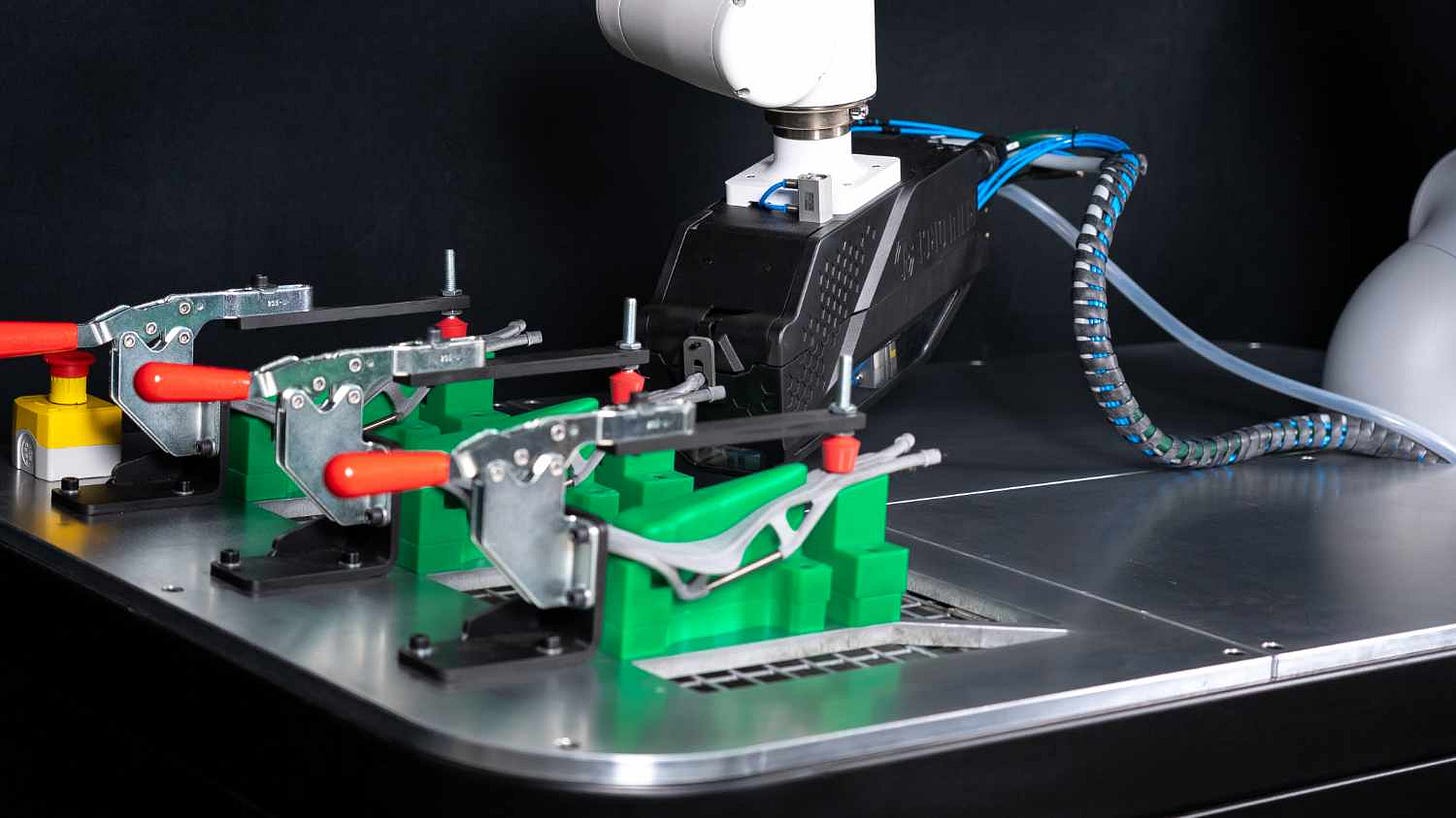

As a result, customers requested more automated and scalable reinforcement solutions. This led to the development of the Modular Delta system - an integrated, robot-based, fully automated reinforcement cell designed for continuous operation in production environments. The system was showcased at Formnext 2025.

Modular Delta integrates the Delta hardware with a robotic system for autonomous part handling, positioning, and reinforcement. This configuration enables continuous operation with minimal human intervention, allowing manufacturers to scale their reinforcement processes with higher throughput, repeatability, and process control.

The cell is equipped with a closed-loop monitoring system that tracks key parameters in real time - such as injection pressure, fiber flow, and reinforcement length - ensuring repeatability and full traceability, even for complex geometries.

In this configuration, Modular Delta can process multiple parts sequentially or in batches, adapting to production environments.

Finally, it’s worth stating something that may seem obvious but is sometimes overlooked - CFIP can be applied in any industrial manufacturing sector, not only in 3D printing. It’s just that 3D printing enables the creation of the most complex internal channels, where continuous fiber injection is unmatched.

And that’s it…

I encourage you to explore the topic further, because it truly stands apart from everything else in 3D printing. It also represents a very interesting counterbalance to solutions that use continuous fiber directly within the 3D printing process itself.

Afterword:

This is the first issue of the 3DP War Journal newsletter in 2026 and an announcement of several new features and changes. The first is that we are ending the publication of weekly news summaries here. This section is moving to the relaunched ATOMIC LAYERS series on The 3D Printing Journal, which was restarted last Friday.

Yes - NEWS & GOSSIP are back. From now on, they will be published weekly, every Friday:

The second change I’ll be testing over the coming weeks is a subtle shift in the format here. Instead of the usual industry and market analysis articles, I want to focus more on profiling interesting people and companies from the industry and highlighting their achievements.

First up are my good friends at REINFORCE3D. In the coming weeks, I hope to present other equally interesting companies and their projects.

Industry and market-focused articles will move to the Friday ATOMIC LAYERS. At least, that’s the plan for now… Ultimately, it’s up to you whether this approach resonates.

This is exciting! I had thought that this might be a better approach but I didn't know it was possible.

I am designing an FFF slicer that can do overhangs up to full 90 deg. Aside from overhangs it will enable printing hollow objects which could then be filled with other materials. (And it looks like carbon fiber could be one of them!)