What if AM companies always told the truth?

The Atomic Layers: S10E11 (00278)

Atomic Layer of the Day:

Many people feel disappointed with the additive manufacturing industry because they believe they were lied. They bought the stories of various 3D printing evangelists and rode the wave of their beautifully told visions.

Now, as the evangelists' companies have sunk beneath the ocean of market reality—and the evangelists themselves long ago climbed into lifeboats and safely reached shore—any reasonable and honest observer is left clenching their teeth in frustration.

Because they know there's nothing to be done. Those who were meant to lose, lost. And those who profited were often the very people most responsible for the failure.

But what if things had gone differently? What if we lived in a world where manufacturers of 3D printers, materials, software, as well as service providers always told the truth?

Just imagine… Pure facts—no bullshit.

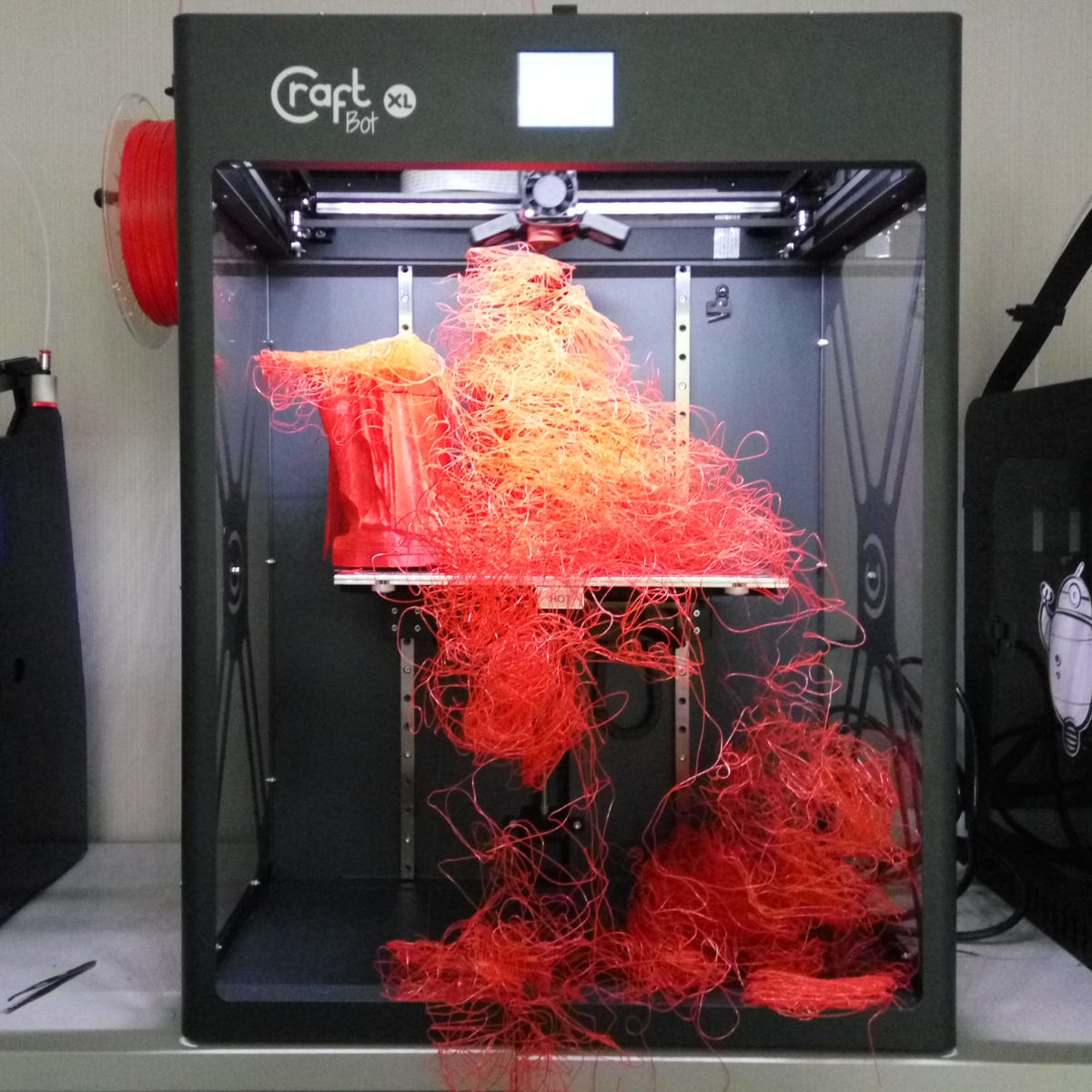

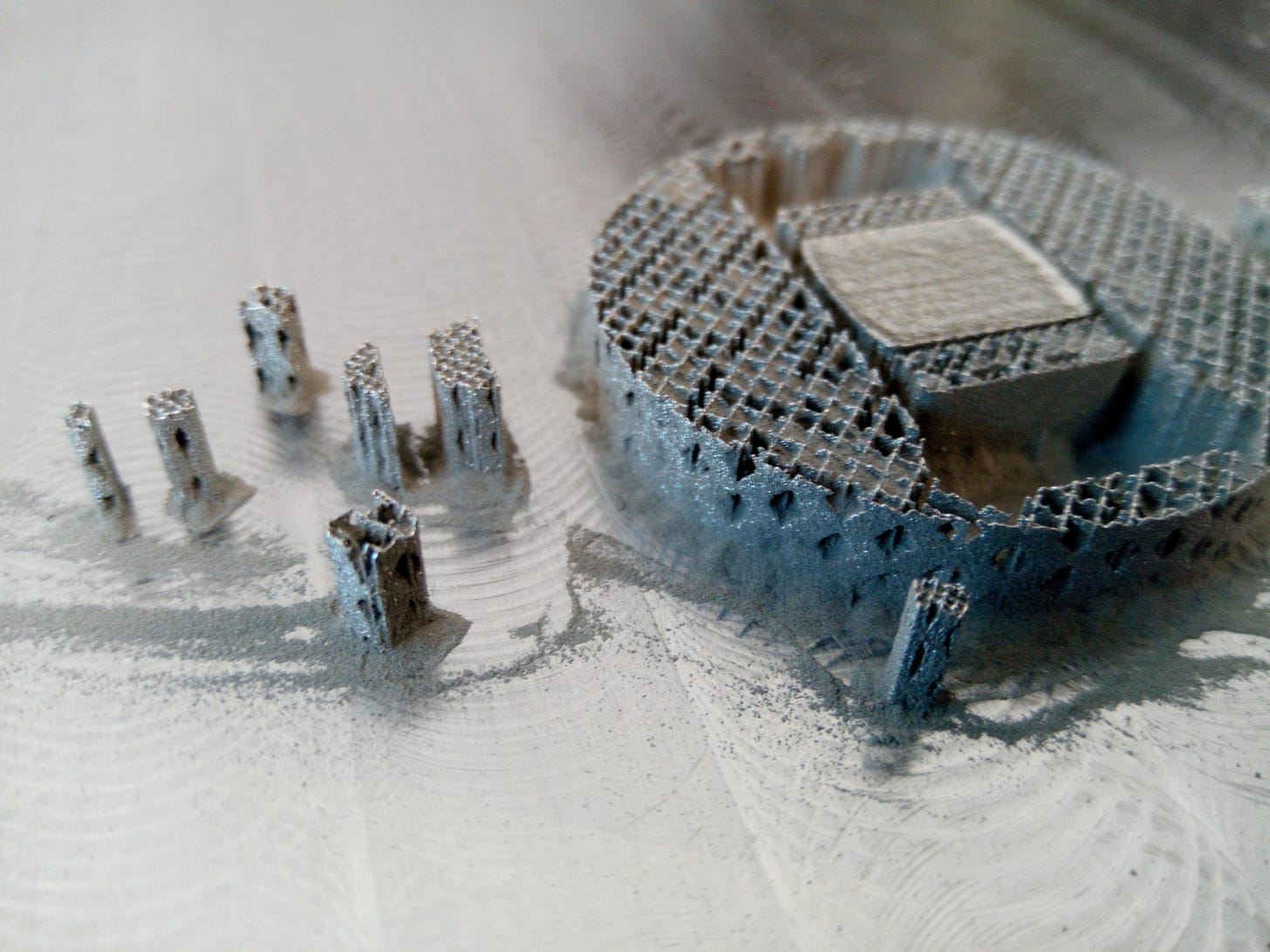

Every product brochure would look like a profit-and-loss statement. Instead of promising injection-molded or cast-quality miracle parts, manufacturers would report, with bureaucratic precision, the percentage of prints that fail and how much material ends up in the trash.

User manuals would read longer than economic treaties, and tech support would openly admit that some factory defects are the result of “engineering improvisation.”

Materials would be classified as “variable-quality raw goods,” with labels detailing moisture levels, porosity, and the probability of a failed print on the first try.

Instead of marketing slogans like “uncompromising strength” and “unmatched precision,” you'd get messages like: “This might work, or it might not—remember to calibrate and change your nozzle regularly.”

3D printing service bureaus wouldn’t show off flawless parts but would highlight their real rejection rate. Offers would include data on the percentage of projects returned to customers with geometric deformities.

As a result, every client would have to sign a disclaimer acknowledging the “risk of defect” and agreeing to pay for test prints and potential rework.

The market's reaction could actually be surprisingly constructive: the rate of price negotiations would rise in proportion to the number of disclosed flaws, and 3D print shops would micro-adjust their pricing daily based on quality stats.

All trade show presentations would become audit-style briefings, featuring charts on material waste and reports on average machine downtime.

The word “innovation” would lose its magical aura and become a synonym for “lengthy validation process.”

The likely consequence of this truth revolution? Market consolidation. Smaller players unable to maintain full cost transparency would collapse faster, while big players—armed with legal and analytics teams—would monopolize the high-end printer market.

Instead of a startup festival, we’d have quarterly earnings reports and 24/7 legal hotlines for concerned users.

No one would actually miss the marketing fairy tales. The industry would become boringly reliable—but rock-solid.

And the customers? Those who survive the initial shock would become the most loyal ambassadors of 3D printing.

Wouldn’t that be something…?

Atomic Layer from the Past:

05-11-2021: Grupa Azoty introduced Tarfuse Envi.

News & Gossip:

restor3d has launched the Aeros Modular Stem Total Ankle System, the first anteriorly inserted modular tibial implant for total ankle replacement. FDA-cleared for primary and revision use, it offers improved efficiency, reduced wear, and compatibility with Kinos components, with full commercial release planned for 2026 after limited rollout in 2025.

LEAP 71 is developing two large reference rocket engines—a 200kN aerospike and 2000kN bell-nozzle—using its Noyron computational model and metal 3D printing. Hot fire tests are planned by 2027 and 2029. The scalable approach aims to reduce part counts, speed up development, and adapt to increasing engine size demands.

And finally – tomorrow, in my weekly LinkedIn newsletter, I’ll be sharing a rather important announcement from my side. As they say – one chapter ends, another begins...

We are on the cusp of a huge market shift. Instead of oodles of companies flush with investor dollars blowing sales and marketing budgets and doing free application development and sales engineering, you’ll have a much smaller group of companies much more focused on profitability, telling customers they are going to have to pay for the sales engineering and application development.